Normal-temperature desulfurizer and preparation method thereof

A desulfurization agent, normal temperature technology, applied in separation methods, chemical instruments and methods, copper compounds, etc., can solve the problems that other properties have not been studied, performance has not been studied, and desulfurization is not involved, so as to increase production costs and high precision , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

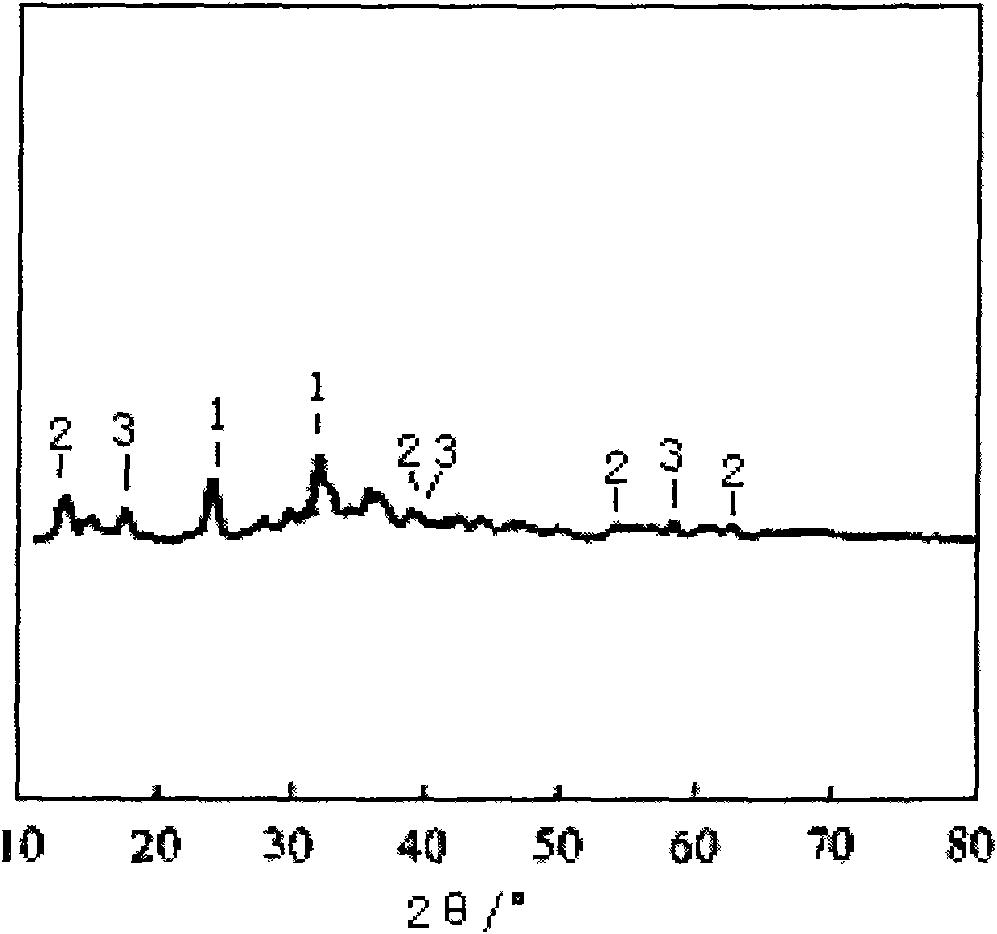

Image

Examples

Embodiment 1

[0020] Weigh 136.4 grams of CuCl 2 .2H 2 O and 27.2 g ZnCl 2 , Placed in a 2000ml reactor with stirring, add 800ml of water, and stir at room temperature until the copper salt and zinc salt are completely dissolved. Weigh 90 grams of solid ammonium carbonate and 13 grams of kaolin, slowly add them to the above mixed solution, then use solid ammonium carbonate to adjust the pH of the solution to 7.5, and continue to stir for 10 minutes. Filter the precipitate, wash the precipitate with water until NH in the eluent 4 + The elution is stopped when the ion mass percentage is less than 0.5%. The precipitate is dried to obtain a filter cake.

[0021] Weigh 95 grams of the above filter cake and 5 grams of binder and mix them with water, wetting and kneading, molding on a small twin-screw extruder, extruding a strip desulfurizer with a diameter of 4mm, drying at 80°C for 8 hours, and making the sulfur content Evaluation showed that the sulfur capacity of the desulfurizer was 33.6%.

[00...

Embodiment 2

[0024] Weigh 181.2 grams of Cu(NO 3 ) 2 ·3H 2 O and 43.6 g Zn(NO 3 ) 2 ·6H 2 O, put in a stirred reactor, add 800ml of water, and stir at room temperature until the copper salt and zinc salt are completely dissolved. Weigh 100 grams of solid sodium carbonate and 11.6 grams of diatomaceous earth, slowly add them to the above mixed solution, then adjust the pH of the solution to 8 with sodium carbonate, and continue to stir for 10 minutes. Filter the precipitate, wash the precipitate with water until Na in the eluent + Stop when the ion mass percentage is less than 0.5%. The precipitate is dried to obtain a filter cake.

[0025] Weigh 99 grams of the above filter cake and 1 gram of binder and mix them with water, wetting and kneading, molding on a small twin-screw extruder, extruding a strip of desulfurizer with a diameter of 4mm, drying at 70°C for 10 hours, and making the sulfur content Evaluation shows that the sulfur capacity of the desulfurizer is 40%.

Embodiment 3

[0027] Weigh 150 grams of CuSO 4 .5H 2 O and 57.5 g ZnSO 4 .7H 2 O, placed in a 2000ml reactor with stirring, add 800ml of water, and stir at room temperature until the copper salt and zinc salt are completely dissolved. Then weigh about 105 grams of solid potassium carbonate and 16 grams of diatomaceous earth, slowly add them to the above mixed solution, then use solid potassium carbonate to adjust the pH of the solution to 8.5, and continue to stir for 15 minutes. Filter the precipitate, wash the precipitate with water until K in the eluent + Stop when the ion mass percentage is less than 0.5%. The precipitate is dried to obtain a filter cake.

[0028] Weigh 97 grams of the above filter cake and 3 grams of binder, mix them with water, knead them, and shape them on a small twin-screw extruder. Extrude a strip desulfurizer with a diameter of 4 mm, dry at 90°C for 4 hours, and make the sulfur capacity It is evaluated that the sulfur capacity of the desulfurizer is 30.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com