Preparation method and application of micro/nano structured LiFePO4 compound

A technology of micro-nano structure and function, applied in structural parts, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of difficult operation of the coating process, and achieve the effects of low price, high gram capacity and good follow-up processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

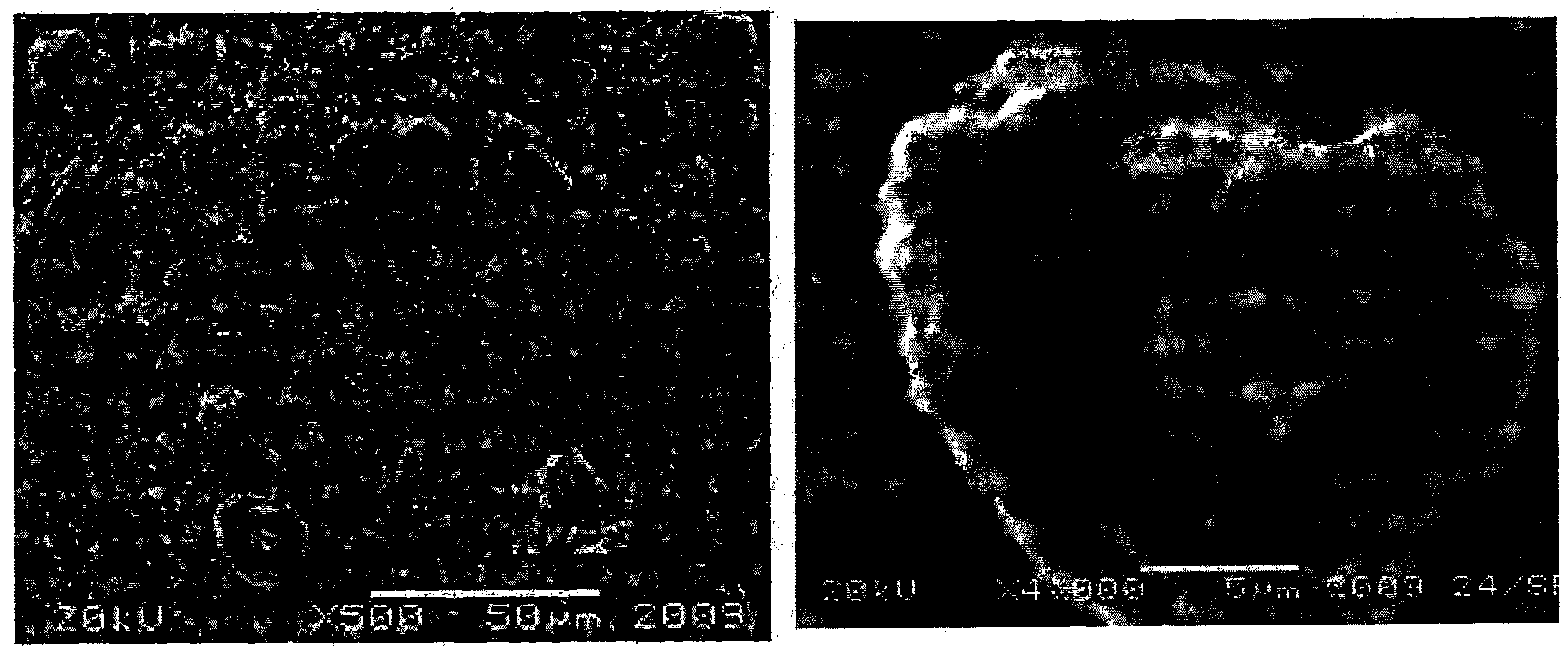

[0035] The preparation method of the invention is simple and easy, and the materials used are cheap and convenient for large-scale production. Prepared LiFePO 4 It has high purity and micro-nano structure, and has good electrochemical performance. When used as a cathode material for lithium-ion batteries, due to its structural characteristics of nano-scale primary crystal grains agglomerated to form micron-scale particles, on the one hand, it retains the advantages of high gram capacity of nano-scale materials, and on the other hand, micron-scale particles are convenient Subsequent coating operations.

[0036] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

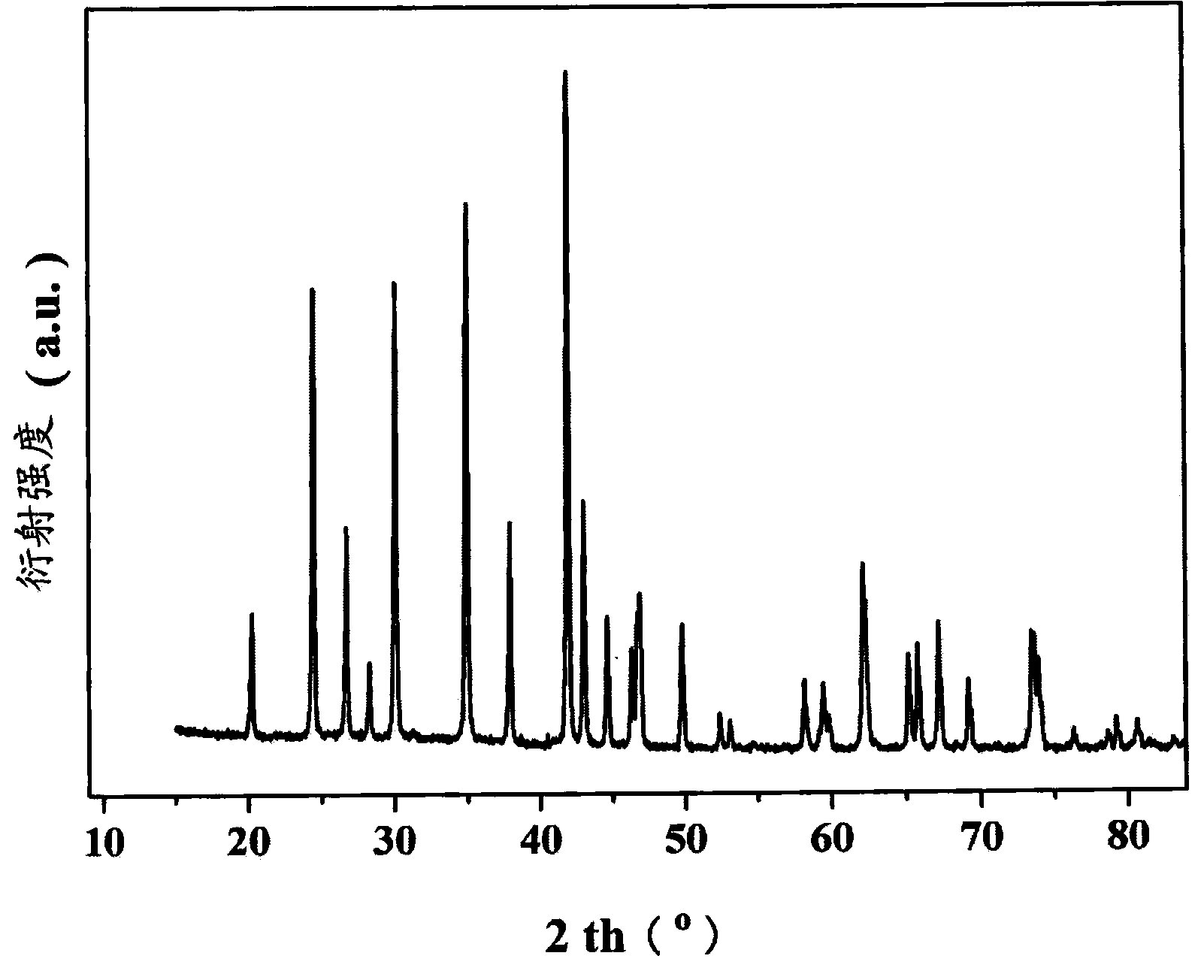

Embodiment 1

[0038] Fe:Li:PO 4 = The ratio of 1:1.05:1 is respectively called ferrous oxalate and LiOH·H 2 O, and NH 4 h 2 PO 4 After mixing evenly, add a small amount of Li which has the effect of molten salt 2 CO 3 , adding an appropriate amount of water to make a slurry, and then roasting under an argon atmosphere to obtain a lithium-ion cathode material - high-purity LiFePO 4 Compound; Li added above 2 CO 3 for LiFePO 4 1% of the product mass, the calcination temperature is 650°C, and the calcination time is 10 hours, then LiFePO with high-purity micro-nano structure can be obtained 4 compound.

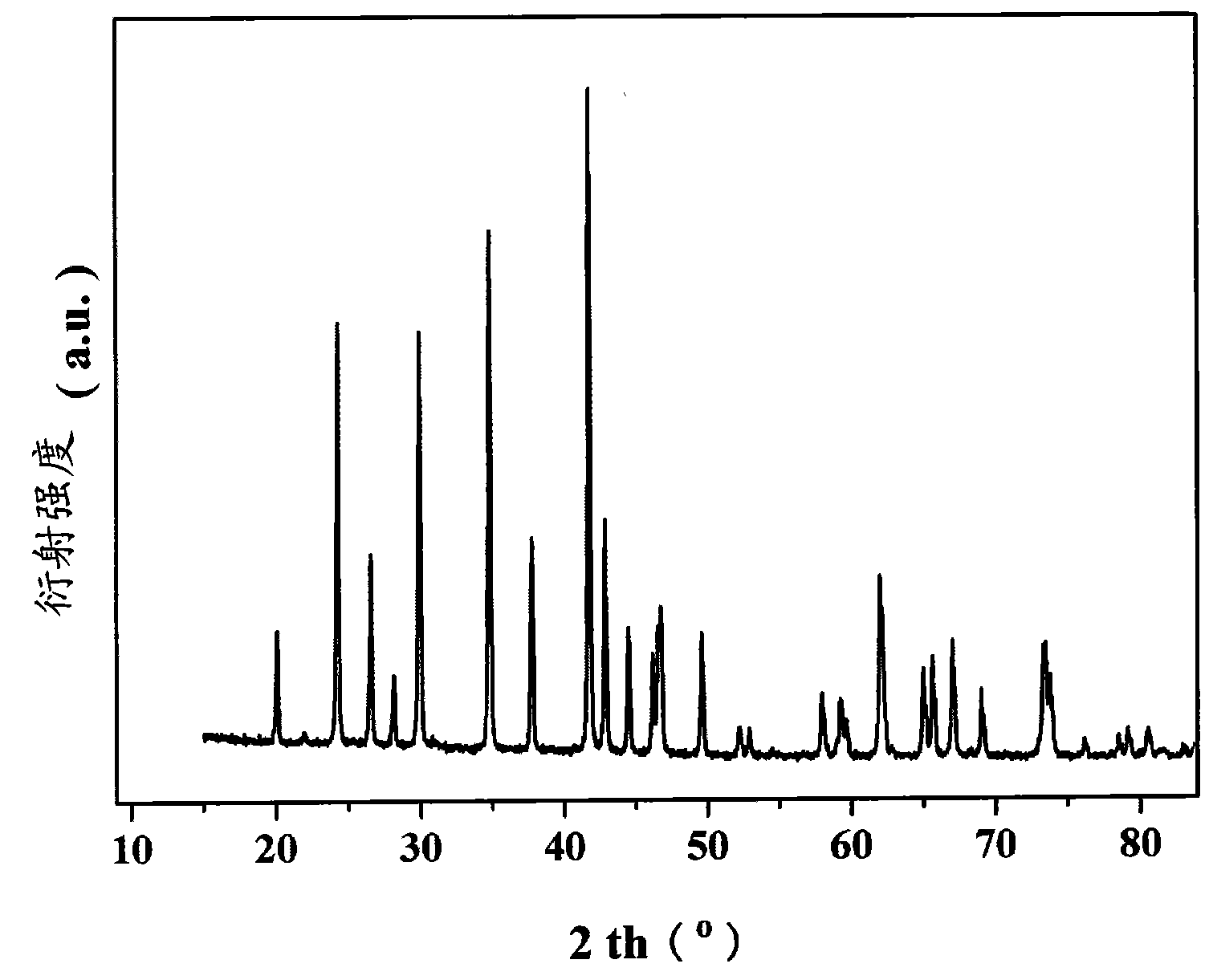

Embodiment 2

[0040] Fe:Li:PO 4 = The ratio of 1:1.05:1 is respectively called ferrous oxalate and Li 2 CO 3 , and NH 4 h 2 PO 4 After mixing evenly, add a small amount of TiO with molten salt effect 2 , adding an appropriate amount of water to make a slurry, and then roasting under an argon atmosphere to obtain a lithium-ion cathode material - high-purity LiFePO 4 compound; the TiO added above 2 for LiFePO 4 3% of the product mass, the calcination temperature is 800°C, and the calcination time is 5 hours, the LiFePO with high-purity micro-nano structure can be obtained 4 compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com