Net soft splicing manufacturing method for splicing adjacent two copper alloy chain link fences

A technology of copper alloy and mesh, which is applied in the splicing field of copper alloy trapezoidal nets in aquaculture cages, can solve the problems of widespread use of copper alloy trapezoidal nets, restrict the sustainable development of fishery projects, and damage the wires of trapezoidal nets, etc. , to achieve the effect of improving quality and its comprehensive performance, improving anti-fouling function and service life, and reducing morbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Illustrate the best mode of the present invention below in conjunction with accompanying drawing:

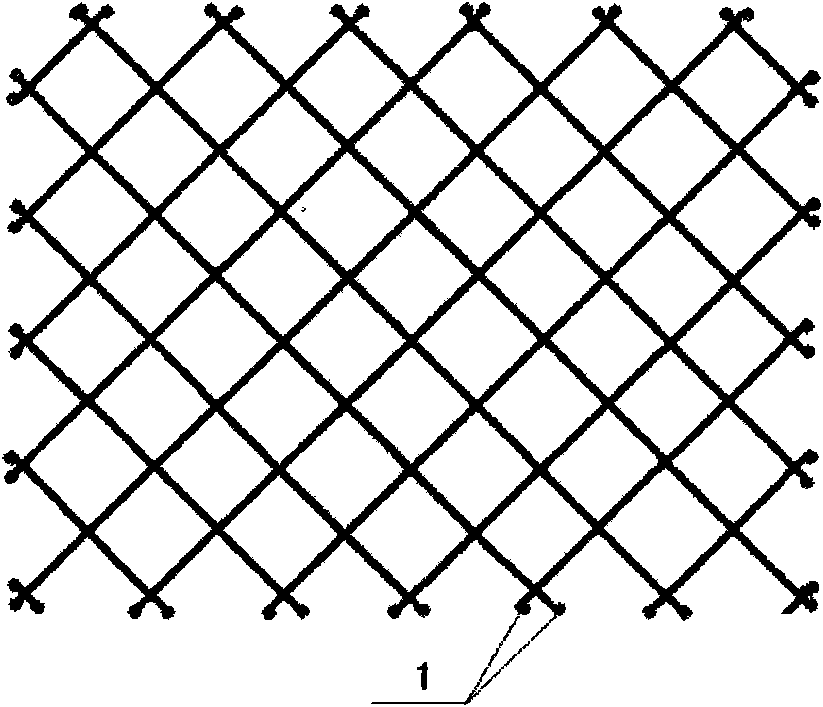

[0010] figure 1 1 in represents the mesh feet of the mesh soft connector after melting treatment.

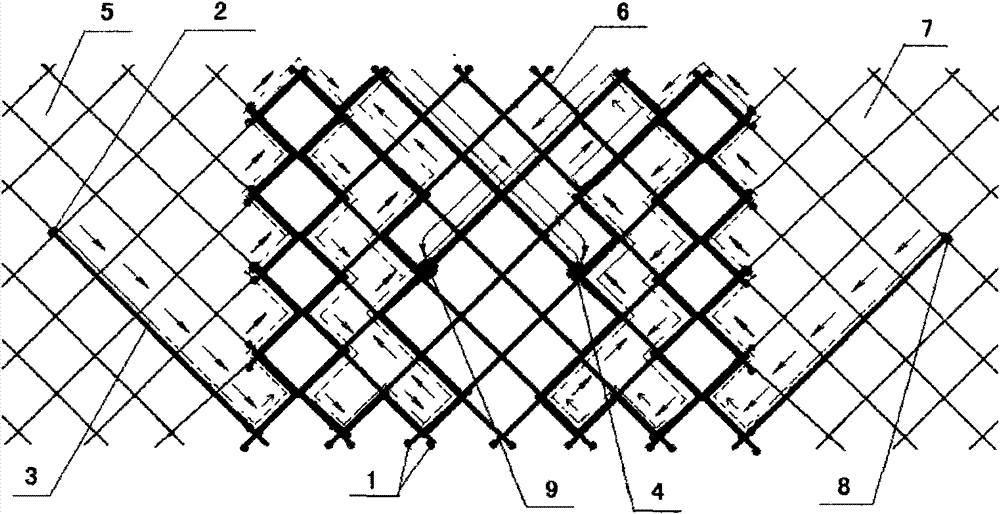

[0011] figure 2 The 1 in the mesh represents the mesh foot of the mesh after the melting method on the soft connector, figure 2 The 2 in it represents the starting point of the suture line when the mesh soft connector is spliced with a piece of copper alloy orthorhombic mesh, figure 2 The 3 in it represents the general direction of the suture line when splicing the mesh soft connector and the copper alloy orthorhombic mesh, figure 2 The 4 in it represents the end point of the suture line when the mesh soft connector is spliced with a piece of copper alloy orthorhombic mesh, figure 2 5 in represents the first piece of copper alloy orthorhombic mesh that needs to be spliced, figure 2 The 6 in it represents the mesh soft connector, figure 2 7 in represents ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com