Large-thickness Cr-Mo system 12Cr2Mo1R container steel and production method thereof

A 12cr2mo1r, production method technology, applied in the direction of temperature control, rolling force/roll gap control, etc., can solve the problems of long purchase cycle, low market supply, high price, etc., and achieve good high temperature tensile properties, good plastic toughness Energy, high temperature performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

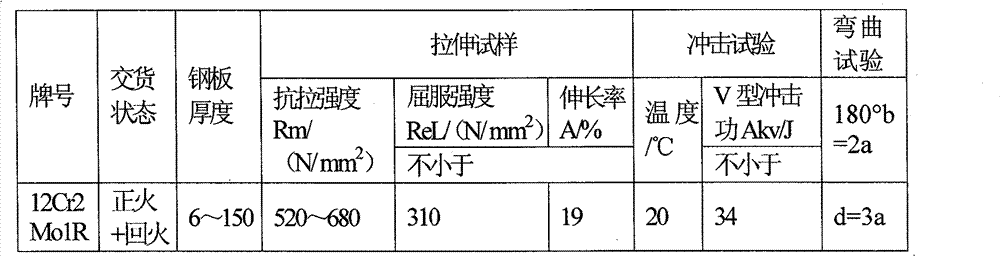

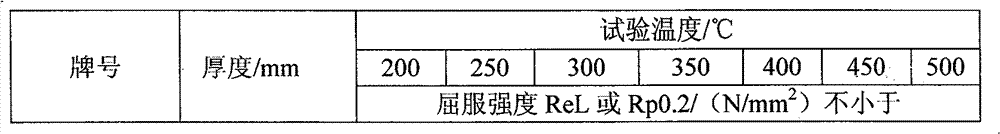

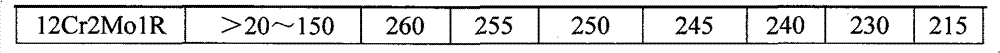

[0016] Example 1: A large-thickness Cr-Mo-based 12Cr2Mo1R container steel, comprising the following chemical components in mass percentage (unit, wt%): C: 0.11, Si: 0.45, Mn: 0.35, P: 0.017, S: 0.004, Cr: 2.00, Mo 1.10AlS: 0.040, others are Fe and residual elements;

Embodiment 2

[0018] A large-thickness Cr-Mo system 12Cr2Mo1R container steel, comprising the following chemical components in mass percent (unit, wt%): C: 0.14, Si: 0.25, Mn: 0.55, P: 0.010, S: 0.010, Cr: 2.50, Mo 0.90, AlS: 0.020, others are Fe and residual elements;

Embodiment 3

[0020] A large-thickness Cr-Mo series 12Cr2Mo1R container steel, comprising the following chemical components in mass percent (unit, wt%): C: 0.12, Si: 0.35, Mn: 0.45, P: 0.013, S: 0.007, Cr: 2.20, Mo 1.00, AlS: 0.030, others are Fe and residual elements;

[0021] For the above-mentioned large-thickness Cr-Mo-based 12Cr2Mo1R container steel, the thickness of the steel plate is 120-150mm.

[0022] In order to achieve the above purpose, during the smelting process, harmful elements such as P (phosphorus) and S (sulfur) in steel are strictly controlled to ensure that the purity of molten steel basically reaches the level of clean steel. In the subsequent rolling and heating process, increase the final rolling temperature to prevent cracks caused by excessive internal stress of the steel plate and improve its plastic deformation. After the steel plate is rolled, it is stacked and slowly cooled to eliminate the internal stress of the steel plate, and then quenched and tempered to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com