High-strength steel plate Q460GJE-Z35 for extra-thick high-rise building structure and production method thereof

A technology of Q460GJE-Z35 and high-strength steel plate, which is applied to high-strength steel plate Q460GJE-Z35 for extra-thick high-rise building structures and its production field, can solve problems such as difficult production and special requirements for process equipment, and reduce metallurgical costs and reduce The effect of molten steel inclusion content and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The process route of the present invention: molten iron KR deep desulfurization→converter smelting→LF refining→VD vacuum treatment→cast ingot pouring→steel ingot heating→phosphorus removal→controlled rolling→controlled cooling→controlled straightening→off-line slow cooling→surface inspection →heat treatment→finishing→flaw detection→testing→judgment→qualified product storage.

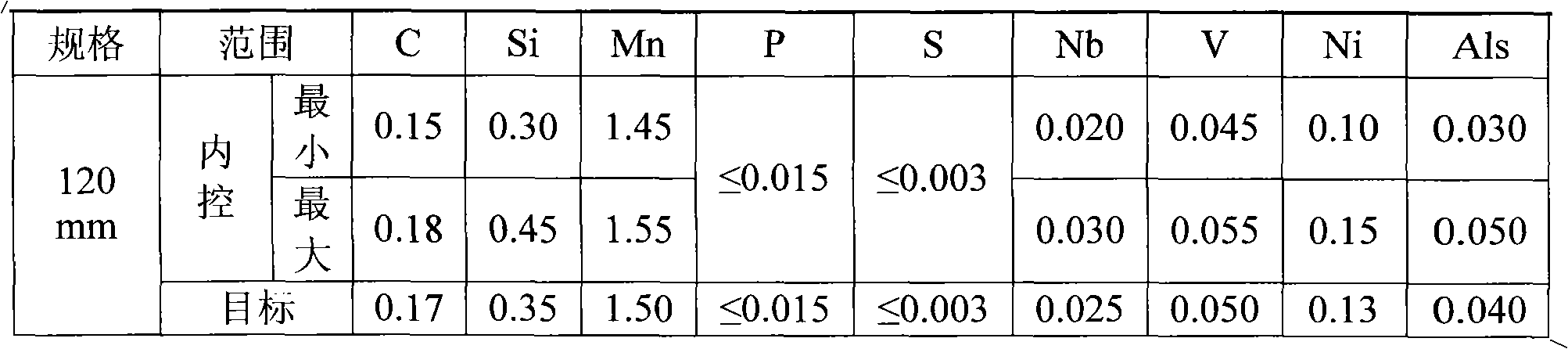

[0017] The specific ingredients are shown in Table 1.

[0018] Table 1: Chemical composition / % of Q460GJE-Z35 steel (liquidus temperature 1519°C)

[0019]

Embodiment 2

[0021] The process route of the present invention: molten iron KR deep desulfurization→converter smelting→LF refining→VD vacuum treatment→cast ingot pouring→steel ingot heating→phosphorus removal→controlled rolling→controlled cooling→controlled straightening→off-line slow cooling→surface inspection →heat treatment→finishing→flaw detection→testing→judgment→qualified product storage.

[0022] The specific ingredients are shown in Table 2.

[0023] Table 2: Chemical composition / % of Q460GJE-Z35 steel (liquidus temperature 1519°C)

[0024]

Embodiment 3

[0026] The process route of the present invention: molten iron KR deep desulfurization→converter smelting→LF refining→VD vacuum treatment→cast ingot pouring→steel ingot heating→phosphorus removal→controlled rolling→controlled cooling→controlled straightening→off-line slow cooling→surface inspection →heat treatment→finishing→flaw detection→testing→judgment→qualified product storage.

[0027] The specific ingredients are shown in Table 3.

[0028] Table 3: Chemical Composition / % of Q460GJE-Z35 Steel (Liquidus Temperature 1519°C)

[0029]

[0030] In order to ensure qualified flaw detection, the compression ratio should be at least ≥5. Choose 24T, 26T, 32T, 33T for conventional scale ingots, choose 36-40T for water-cooled mold ingots, and choose 36T water-cooled molds. Design requirements.

[0031] Smelting process, tapping carbon ≥ 0.06%, tapping P ≤ 0.012%, S ≤ 0.012%; the number of spot blowing should not exceed 2 times to avoid slag during tapping. A large amount of sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com