Ultraviolet-cured coating composition and mobile phone key

A technology for curing coatings and compositions, applied in the direction of polyurea/polyurethane coatings, coatings, etc., which can solve the problems of poor substrate adhesion, poor storage performance, unsatisfactory coating wear resistance, scratch resistance, etc. Achieve the effects of strong wetting performance, improved storage performance, and good anti-scratch ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In the preparation method of the ultraviolet curing coating of the present invention, the main resin, the diluent, the pigment and the photoinitiator can be mixed simultaneously or step by step. In a preferred situation, the pigment can be added to the aromatic acid acrylate half ester first, and dispersed using a ball mill, high-speed disperser or three-roll mill; and then the remaining main resin, photoinitiator, and part of the diluent are mixed with the above-mentioned pigment dispersion system ;Finally add the remaining diluent and mix well. The above mixing is usually carried out at normal temperature, and if necessary, it can be slightly heated to 30-60°C to speed up the mixing. In this preferred method, there is no special requirement on the amount of each part of the diluent, as long as the components are fully dissolved or diluted.

[0025] If one or more of additives such as leveling agent, defoamer, and dispersant are added to the paint, the above preparati...

Embodiment 1

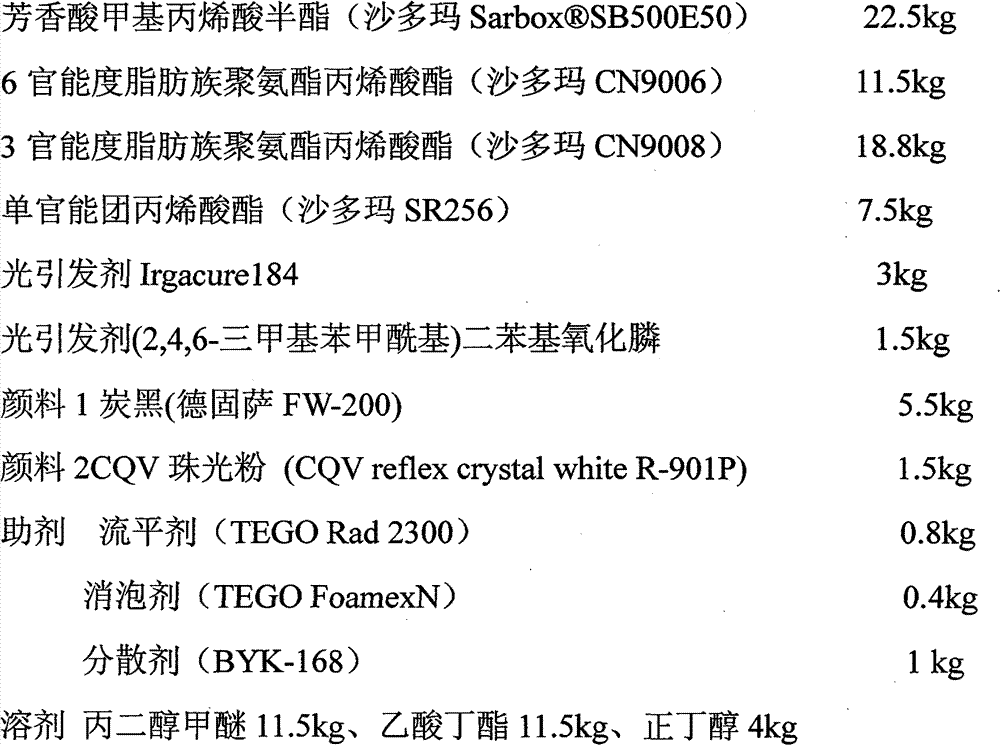

[0032] 1) Coating composition

[0033]

[0034] 2) mixed

[0035] a. Stir the aromatic acid methacrylate half ester under the disperser, add BYK-168 during the stirring process, then mix in the pigment 1 carbon black and 1 / 2 of the acrylic monomer, and grind it with a three-roll mill until the fineness is Below 10 microns.

[0036] b. Add urethane acrylate, additives, and photoinitiators to the material obtained in step a, and disperse evenly with a high-speed disperser at about 2000r / min.

[0037] c. Prepare the solvent according to the proportion and mix well.

[0038] d. Mix the substance obtained in step b with the solvent obtained in step c, add pigment 2 pearl powder, and disperse at a high speed of about 1500r / min until uniform.

[0039] 3) Preparation of mobile phone buttons

[0040] a. Take the 500-frame PC button, install the fixture, use a clean dust-free cloth dipped in alcohol or white electric oil to wipe, and wash off the dirt and release agent.

[0041]...

Embodiment 2-7

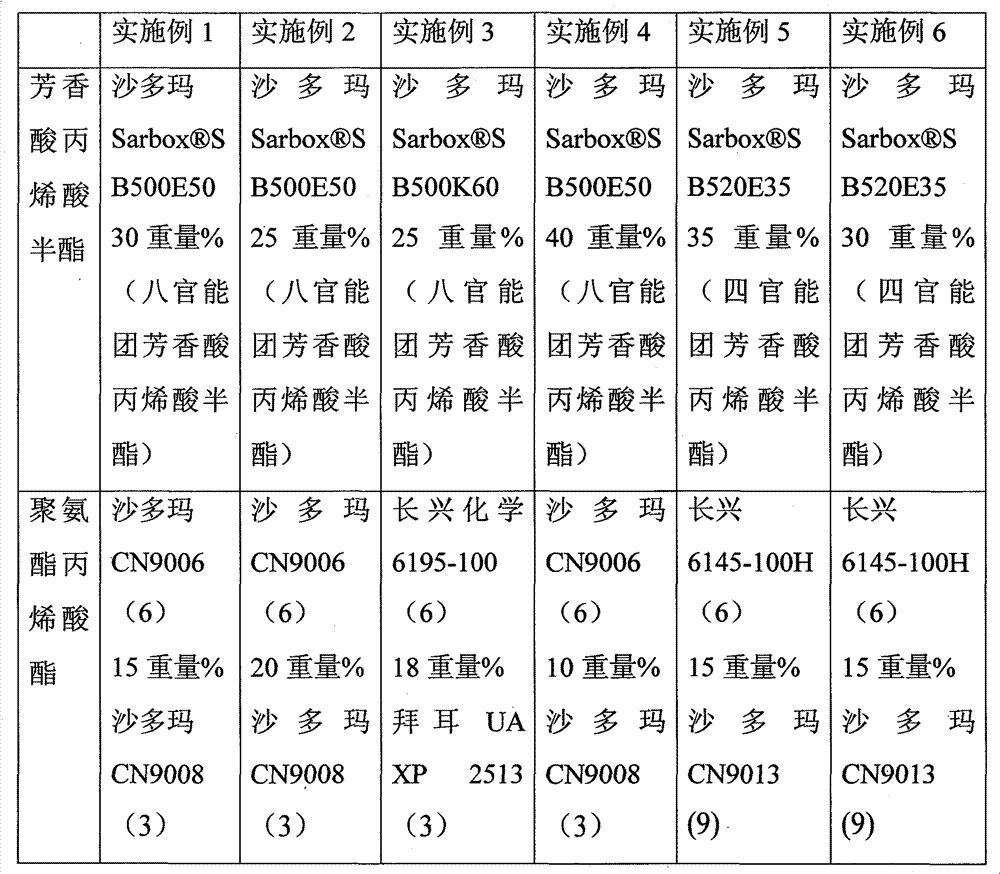

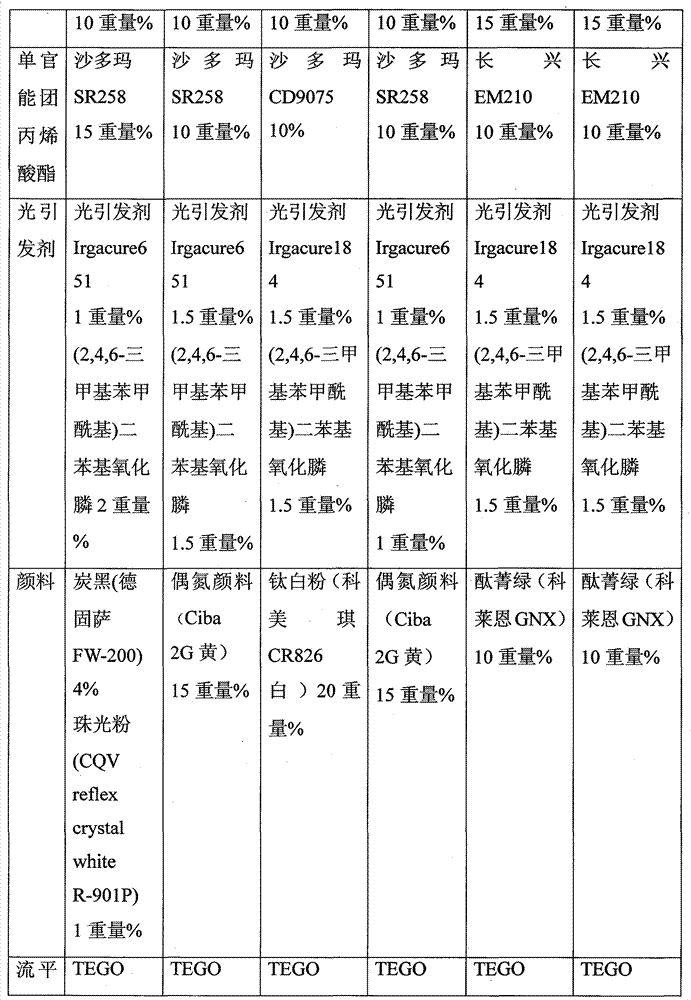

[0047] The same method as in Example 1 was used to mix the coating composition and prepare the keypad of the mobile phone, except for the coating composition, as shown in Table 1.

[0048] Table 1

[0049]

[0050]

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com