Method for generating high repetition frequency ultrashort laser pulse

A high repetition rate, ultra-short laser technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problem of increasing the heat load of the pulse picker drive power supply, which is not conducive to increasing the laser repetition rate and increasing the cost of the laser system and other problems, to achieve the effects of suppressing spontaneous emission light amplification, prolonging life, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

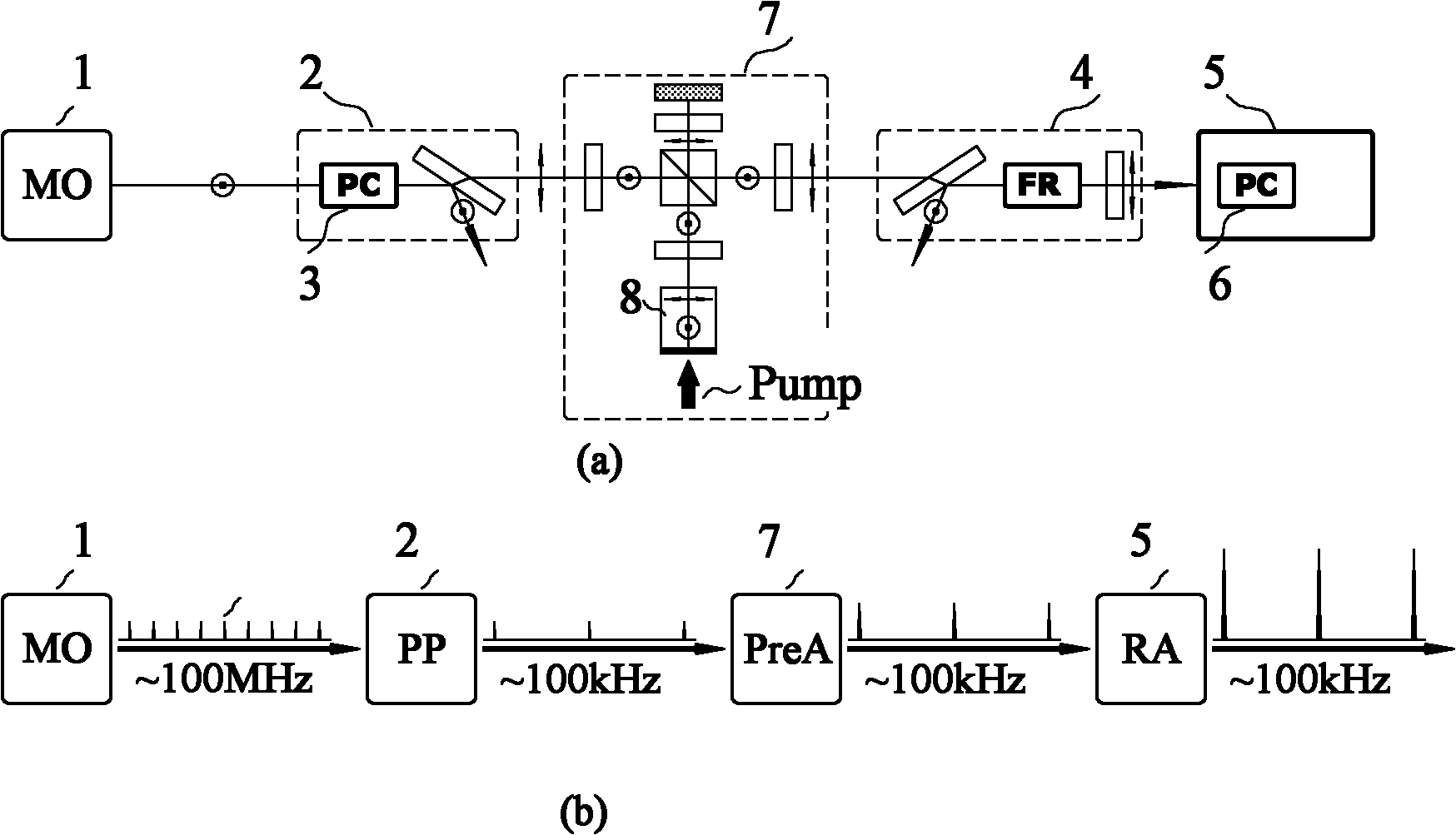

[0043] The cavity-empty SESAM mode-locked laser 8 adopts a semiconductor laser 9 (continuously) as the pumping source of the laser crystal 11, and the semiconductor laser is focused into the laser crystal 11 after being shaped by a collimating mirror 10a and a focusing mirror 10b, and the collimating and focusing mirror 10a, 11b is plated with a dichroic film that is anti-reflective to the pump wavelength and fully reflects the oscillating laser to prevent the light leakage from the laser resonator from being focused by the collimating and focusing mirrors 10b and 10a to damage the pump source. The end face 11a of the laser crystal facing the pump source is coated with a dichroic film that is anti-reflective to the wavelength of the pump light and highly reflective to the wavelength of the oscillating light. Picosecond laser system, the material of laser crystal 11 is Nd:YAG, Nd:YLF, Nd:YVO4, Nd:GdVO4, etc. For femtosecond laser system, the material of laser crystal 11 is Nd:Gl...

specific Embodiment 2

[0045] The cavity-empty SESAM mode-locked laser 8 uses a semiconductor laser 9 (quasi-continuous) as the pumping source of the laser crystal 11. The semiconductor laser is focused into the laser crystal 11 after being shaped by the collimating mirror 10a and the focusing mirror 10b, and the collimating and focusing mirror 10a , 11b is plated with a dichroic film that is anti-reflective to the pump wavelength and fully reflects the oscillating laser, preventing the light leakage of the laser resonator from being focused by the collimating focusing lens 10b, 10a and damaging the pump source. The end face 11a of the laser crystal facing the pump source is coated with a dichroic film that is anti-reflective to the wavelength of the pump light and highly reflective to the wavelength of the oscillating light. Picosecond laser system, the material of laser crystal 11 is Nd:YAG, Nd:YLF, Nd:YVO4, Nd:GdVO4, etc. For femtosecond laser system, the material of laser crystal 11 is Nd:Glass, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com