Flame-retardant cable

A cable and a common technology, applied in the field of fireproof cables and flame retardant, can solve the problems of high flame retardant temperature, easy to be affected by moisture and deformation, and reduce cable performance, etc., to achieve good mechanical properties and temperature resistance and flame retardant performance, excellent results, The effect of low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

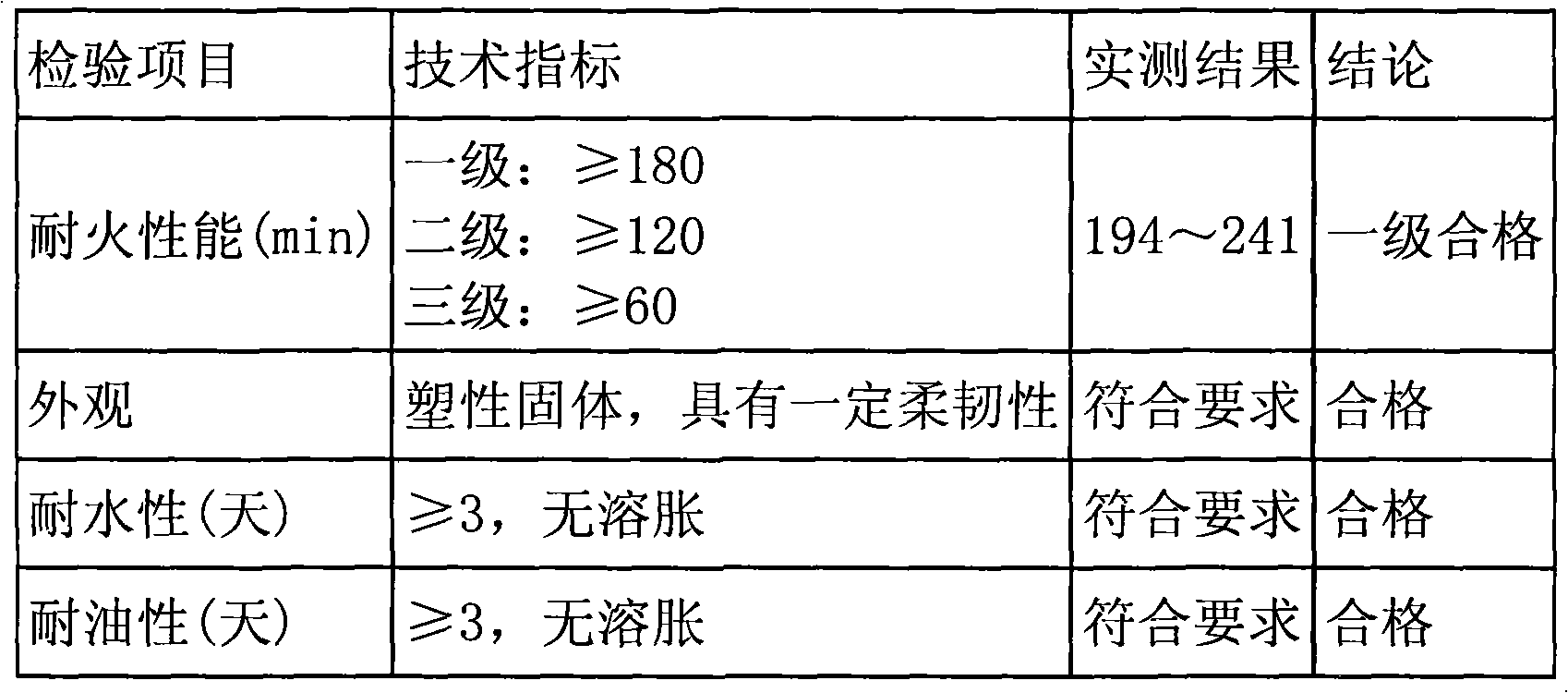

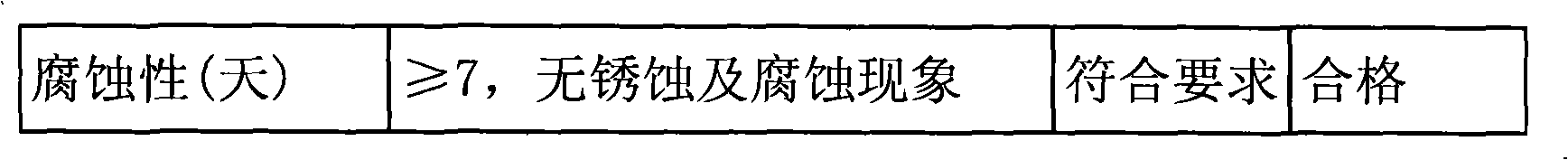

Image

Examples

Embodiment 1

[0021] A cable according to the present invention, wherein the insulating rubber contains three wires, wherein the wires are composed of wires covered with an insulating layer; wherein there are three wires twisted together, and the three wires The wires are coated with fireproof paint. The above-mentioned outer insulating layer has a thickness of 5mm.

[0022] The preparation method of the fireproof coating is as follows: Accurately weigh according to the molar ratio of dimerized linoleic acid and diamine as 1:1, preheat the dimerized linoleic acid to 125°C, gradually add the mixed diamine dropwise, and wait for 20 minutes After the internal drop is completed, slowly increase the reaction temperature at a heating rate of 20°C / h until it rises to 235°C, then add accurately weighed, preheated liquid nitrile rubber; keep this temperature for at least 1 hour, and measure and distill When the water out reaches 80% of the theoretical amount, it can be decompressed gradually; final...

Embodiment 2

[0025] A cable according to the present invention, wherein the insulating rubber contains three wires, wherein the wires are composed of wires covered with an insulating layer; wherein there are three wires twisted together, and the three wires The wires are coated with fireproof paint. The above-mentioned outer insulating layer has a thickness of 1mm.

[0026] The preparation method of the fireproof coating is as follows: according to the molar ratio of dimerized linoleic acid and diamine is 0.92:1, accurately weigh, preheat the dimerized linoleic acid to 125-130 ° C, gradually add the mixed diamine, After dropping within 50 minutes, slowly increase the reaction temperature at a heating rate of 20°C / h until it reaches 235°C, add accurately weighed, preheated liquid nitrile rubber; keep this temperature for at least 1 hour, and Measure the distilled water, when it reaches 80% of the theoretical amount, you can gradually reduce the pressure; finally complete the whole reaction...

Embodiment 3

[0029] A cable according to the present invention, wherein the insulating rubber contains three wires, wherein the wires are composed of wires covered with an insulating layer; wherein there are three wires twisted together, and the three wires The wires are coated with fireproof paint. The above-mentioned outer insulating layer has a thickness of 20 mm.

[0030] The preparation method of the fireproof coating is as follows: Accurately weigh according to the molar ratio of dimerized linoleic acid and diamine as 1.12:1, preheat the dimerized linoleic acid to 130°C, gradually add the mixed diamine dropwise, at 20 After dropping within -50min, slowly increase the reaction temperature at a heating rate of 20°C / h until it reaches 235°C, add accurately weighed, preheated liquid nitrile rubber; keep this temperature for at least 1 hour, and Measure the water that distills out, when reaching 80% of theoretical amount, can carry out gradual decompression; Finally complete whole reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com