Chromatographic photoionization detector

A photoionization and detector technology, applied in the field of chromatographic photoionization detectors, can solve the problems of low reliability and sensitivity, and achieve the effects of improving sensitivity, reducing adhesion, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

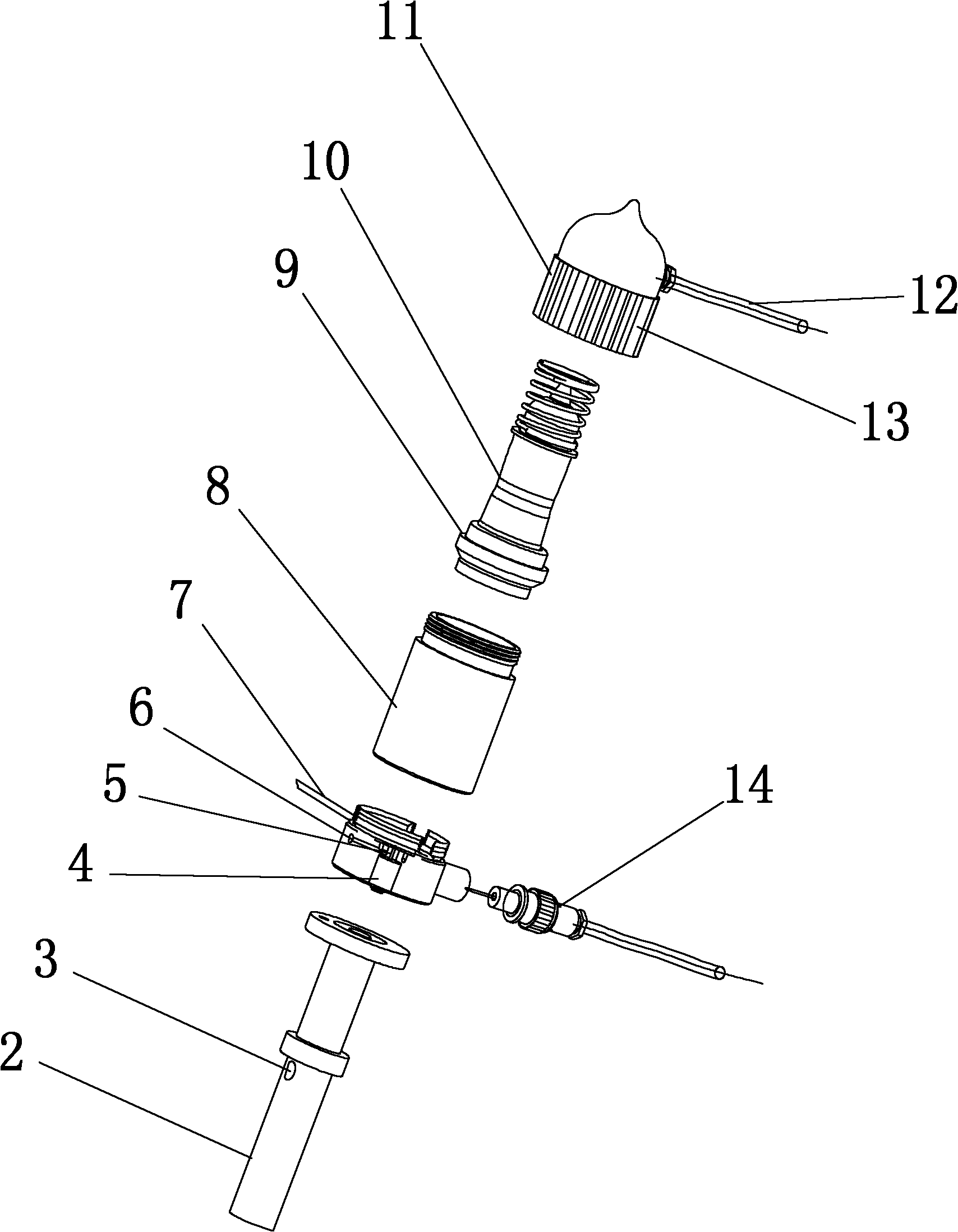

[0035] Example 1, such as figure 1 As shown, the main body of the entire chromatographic photoionization detector is cylindrical, and the external physical dimensions are φ27mm in diameter and 81mm in height. The chromatographic column is connected through the chromatographic connecting column 2. In order to prevent the sample peak from broadening or tailing, a makeup interface 3 is designed on the chromatographic connecting column. The nozzle 4 and the electrode are integrated and embedded in the PID ionization chamber 5 , connected through the probe and the collector joint 14 to realize voltage transmission and signal collection. The volume of the PID ionization chamber is 35μL. There are two gas paths in the PID ionization chamber. One is the exhaust port 6, through which all residual gas is exhausted. The other is the curtain air inlet 7. During use, it can be directly Purging and cleaning the window of the ultraviolet lamp reduces the adhesion of residual samples to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com