Vcsel semiconductor devices with mode control

A conductor and active layer technology, applied in semiconductor lasers, laser parts, electrical components, etc., can solve problems such as high junction temperature, loss, and shortened optical life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

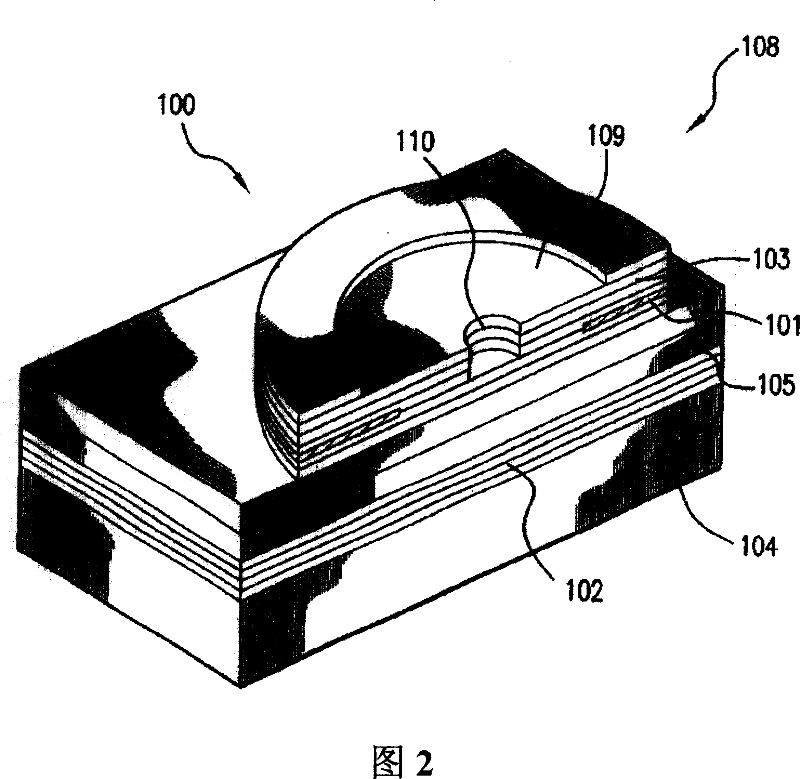

[0051] Details of the invention, including exemplary aspects and embodiments thereof, are set forth below. Referring to the drawings and the following detailed description, like reference numerals are used to designate like or functionally similar elements and are intended to illustrate major features of example embodiments in an extremely simplified illustration. Moreover, the drawings are not intended to depict every feature of actual embodiments nor relative dimensions of the elements shown, nor are they drawn to scale.

[0052] Referring to FIG. 1a, it shows a partial cross-sectional view of a semiconductor structure of an oxide-confined VCSEL known in the prior art. Specifically, the VCSEL 100 includes a laser cavity region 105 defined between a first semiconductor region 102 forming a first mirror stack and a second semiconductor region 103 forming a second mirror stack. between. Semiconductor regions 102 and 103 are disposed on a substrate 104 which may typically be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com