Dendrite corrosion low-power checkout integration method

A low-magnification inspection and surface inspection technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems that are difficult to achieve, and achieve the best matching, reasonable arrangement, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The steps of the integrated method for low power inspection of dendritic corrosion are as follows.

[0052] 1. Sample processing

[0053] First, place the test surface of the tested sample facing up, clamp it on the milling, grinding, and polishing combined machine tool, and use a milling head to mill the test surface of the sample; secondly, use a grinding head to polish the test surface, and the roughness requirement reaches Ra ≤0.8μm; then the inspection surface is polished with a polishing head, and the roughness is required to reach Ra≤0.1μm, that is, the mirror finish is achieved.

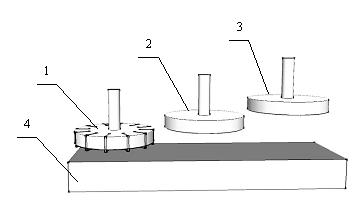

[0054] A milling head, a grinding head and a polishing head are sequentially arranged above the sample inspection surface of the milling, grinding and polishing combined machine tool.

[0055] 2. Sample corrosion

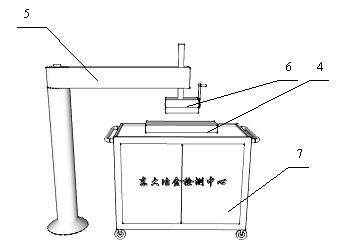

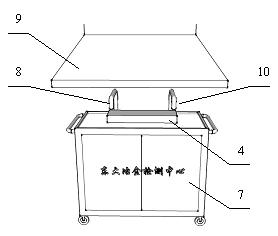

[0056] Loosen the clamping screws of the sample on the milling, grinding, and polishing machine tool, use a magnetic hoist to hoist the sample onto the sample transport trolley, push...

Embodiment 2

[0069] The steps of the integrated method for low power inspection of dendritic corrosion are as follows.

[0070] 1. Sample processing

[0071] First, place the test surface of the tested sample facing up, clamp it on the milling, grinding, and polishing combined machine tool, and use a milling head to mill the test surface of the sample; secondly, use a grinding head to polish the test surface, and the roughness requirement reaches Ra ≤0.8μm; then the inspection surface is polished with a polishing head, and the roughness is required to reach Ra≤0.1μm, that is, mirror finish.

[0072] A milling head, a grinding head and a polishing head are sequentially arranged above the sample inspection surface of the milling, grinding and polishing combined machine tool.

[0073] 2. Sample corrosion

[0074] Loosen the clamping screws of the sample on the milling, grinding, and polishing machine tool, use a magnetic hoist to hoist the sample onto the sample transport trolley, push the trolley int...

Embodiment 3

[0087] The steps of the integrated method for low power inspection of dendritic corrosion are as follows.

[0088] 1. Sample processing

[0089] First, place the test surface of the tested sample facing up, clamp it on the milling, grinding, and polishing combined machine tool, and use a milling head to mill the test surface of the sample; secondly, use a grinding head to polish the test surface, and the roughness requirement reaches Ra ≤0.8μm; then the inspection surface is polished with a polishing head, and the roughness is required to reach Ra≤0.1μm, that is, mirror finish.

[0090] A milling head, a grinding head and a polishing head are sequentially arranged above the sample inspection surface of the milling, grinding and polishing combined machine tool.

[0091] 2. Sample corrosion

[0092] Loosen the clamping screws of the sample on the milling, grinding, and polishing machine tool, use a magnetic hoist to hoist the sample onto the sample transport trolley, push the trolley int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com