Oil level monitoring and oil recharging device for gear box of cooling tower

A technology of gear box oil and oil replenishment device, which is used in gear lubrication/cooling, engine components, engine lubrication, etc., can solve the tedious work of oil replenishment and oil level monitoring, difficulty in maintenance work, and inconvenience for maintenance personnel to stand, etc. problems, to achieve the effect of convenient and quick inspection work, safe and convenient lubrication and maintenance work, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

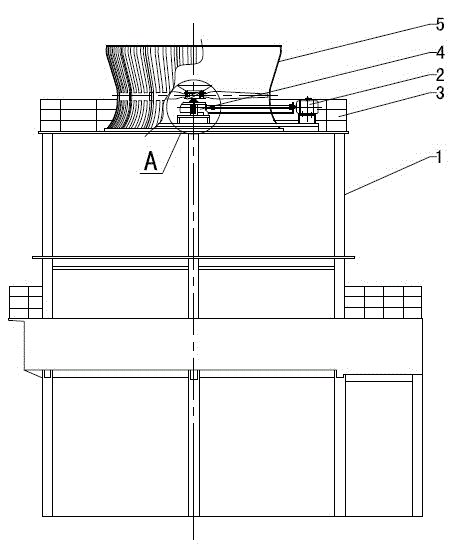

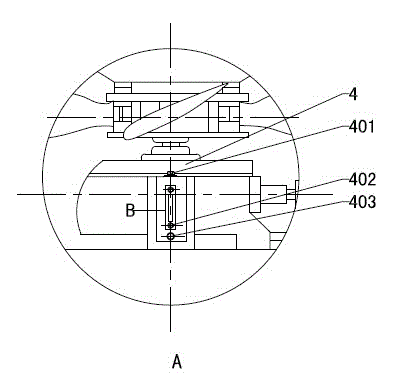

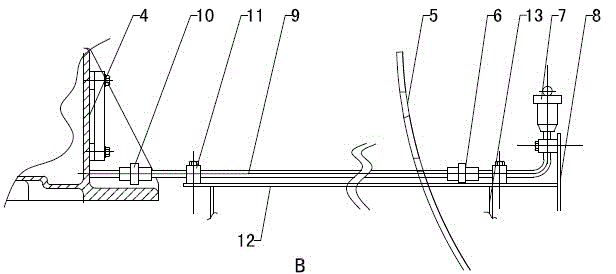

[0020] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0021] Refer to attached Figure 1~3 : the cooling tower gearbox oil level monitoring and oil replenishment device is installed in the inspection channel on the top of the cooling tower, the inspection channel is an annular channel formed by the protective railing 3 around the top of the cooling tower and the outer wall of the diversion cover 5. The cooling tower gearbox oil level monitoring and oil supply device includes oil pipe 9, oil cup 7, fixed bracket 8 and multiple pipe joints. The oil cup 7 and oil pipe 9 are installed through the fixed bracket 8. One end of the oil pipe 9 is connected to the oil outlet of the oil cup 7. The other end is connected to the oil discharge hole 403 of the cooling tower gearbox 4; the height of the upper surface of the oil cup 7 is 30mm higher than the normal working oil l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com