Sonochemical-synergizing-electrochemical method for continuously treating oilfield wastewater

An oilfield sewage and ultrasonic technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as unsatisfactory, achieve high salinity, high iron content, Strong corrosion and scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

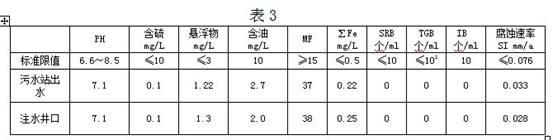

[0035] Incoming water quality of an oilfield sewage station: PH = 6.2, dissolved oxygen = 1.036 mg / L, total iron: 48 mg / L, divalent sulfur: 2.9 mg / L, suspended solids = 53 mg / L, oil content: 156 mg / L, MF = 0, SRB = 10 3 n / ml, TGB = 10 3 n / ml, iron bacteria=10 3 n / ml, the average corrosion rate is 0.6902mm / a, the quality of incoming water shows high iron content, high salinity, and strong corrosion and scaling.

[0036] The oilfield sewage station is treated by sonochemical collaborative electrochemical oxidation method, and the treatment flow rate is 30m 3 / h, the ultrasonic frequency is 20HZ, 10 pairs of electrodes are connected in parallel, the distance between each pair of cathode and anode is 7mm, the anode material is titanium, the cathode material is platinum, the cathode plate thickness is 5mm, and the current density is 50A / h m 2 , in practice, the anode oxidizes the reducing substances in the sewage, such as Fe x (OH) m (3x-m)+And monomeric sulfur, sulfate ...

Embodiment example 2

[0039] For an oilfield sewage station, the incoming water quality indicators are: PH = 6.1, dissolved oxygen = 1.021 mg / L, total iron: 42 mg / L, divalent sulfur: 3.0 mg / L, suspended solids = 50 mg / L, oil content: 149 mg / L, MF = 0, SRB = 10 3 n / ml, TGB = 10 3 n / ml, iron bacteria=10 3 n / ml, the average corrosion rate is 0.661mm / a, and the quality of incoming water shows high iron content, high salinity, and strong corrosion and scaling.

[0040] The oilfield sewage station is treated by ultrasonic and electrochemical oxidation method, and the treatment flow rate is 100m 3 / h, the ultrasonic frequency is 200HZ, 12 pairs of electrodes are connected in parallel, the distance between each pair of cathode and anode is 9mm, the anode material is titanium, the cathode material is graphite, the cathode plate thickness is 30mm, and the current density is 1920A / h m 2 , in practice, the anode will reduce the reducing substances in the sewage, such as Fe x (OH) m (3x-m)+ And monomeric...

Embodiment example 3

[0043] For an oilfield sewage station, the incoming water quality indicators are: PH = 6.2, dissolved oxygen = 1.033 mg / L, total iron: 43 mg / L, divalent sulfur: 2.8mg / L, suspended solids = 55 mg / L, oil content: 150 mg / L, MF = 0, SRB = 10 3 n / ml, TGB = 10 3 n / ml, iron bacteria=10 3 n / ml, the average corrosion rate is 0.682mm / a, the quality of the incoming water shows high iron content, high salinity, and strong corrosion and scaling.

[0044] The oilfield sewage station is treated by the ultrasonic collaborative electrochemical oxidation method, and the treatment flow rate is 200m 3 / h, the ultrasonic frequency is 500HZ, 12 pairs of electrodes are connected in parallel, the distance between each pair of cathode and anode is 15mm, the anode material is graphite, the cathode material is graphite, the thickness of the anode and cathode plates is 30mm, and the current density is 5000A / m 2 , in practice, the anode will reduce the reducing substances in the sewage, such as Fe x ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com