Geothermal floor and junction structure thereof

A geothermal floor and substrate technology, applied in the field of building decoration materials, can solve the problems of difficult heat transfer quickly, low heat conduction efficiency, long heat conduction path, etc., and achieve the effect of short heat conduction path, high heat conduction efficiency, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

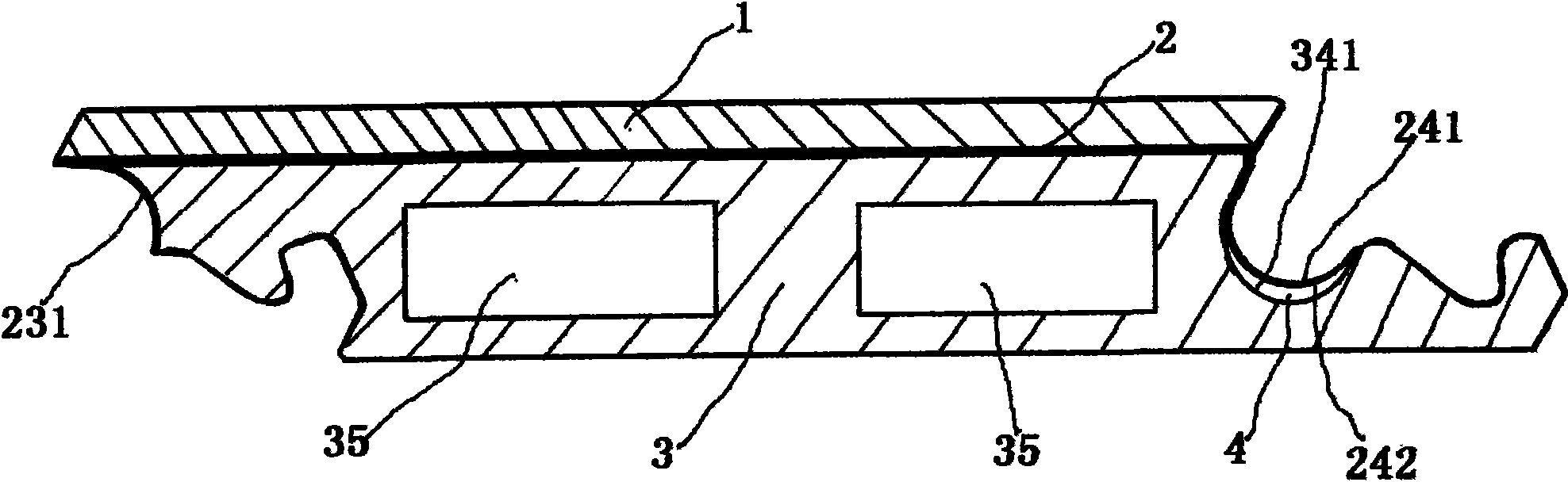

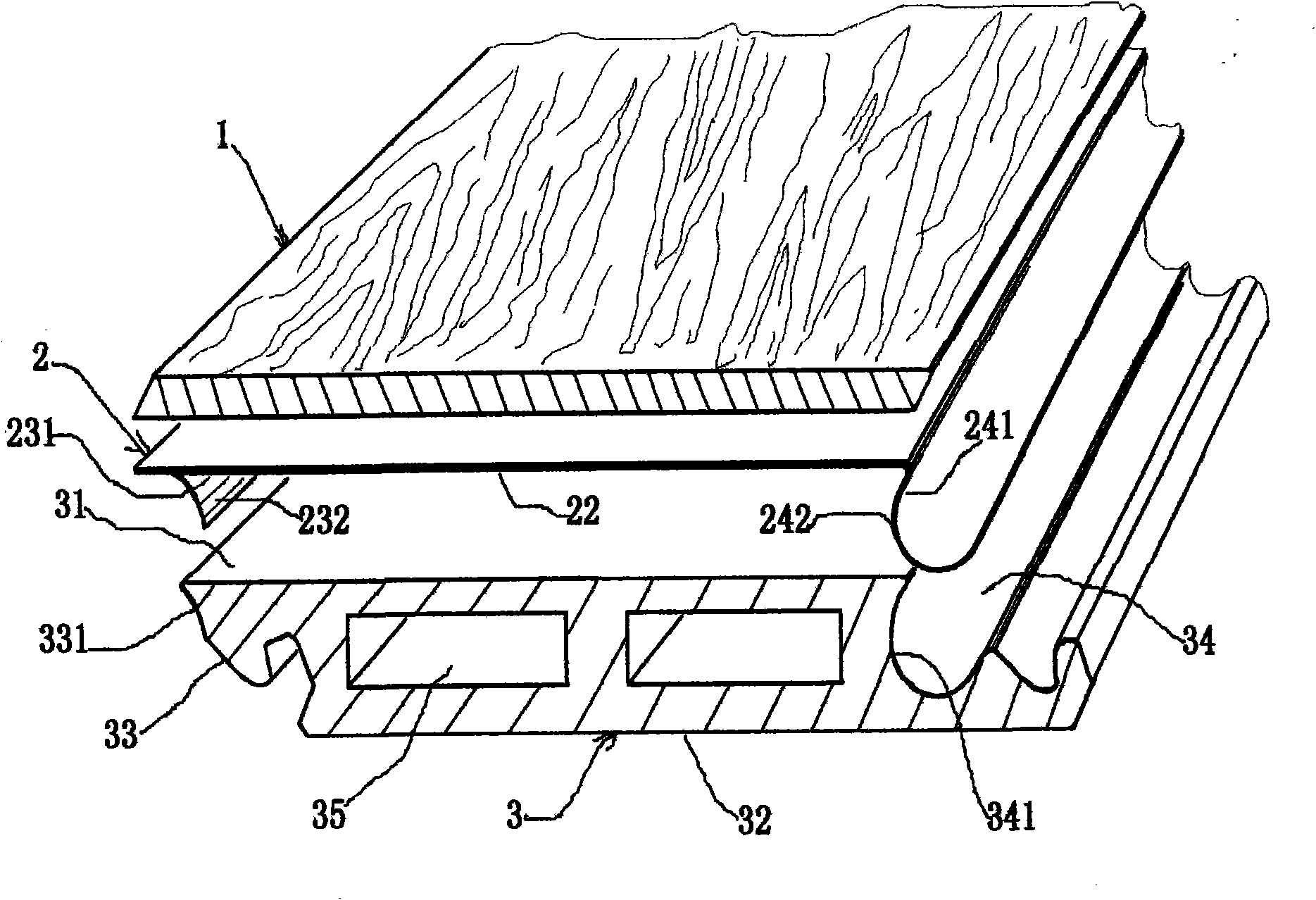

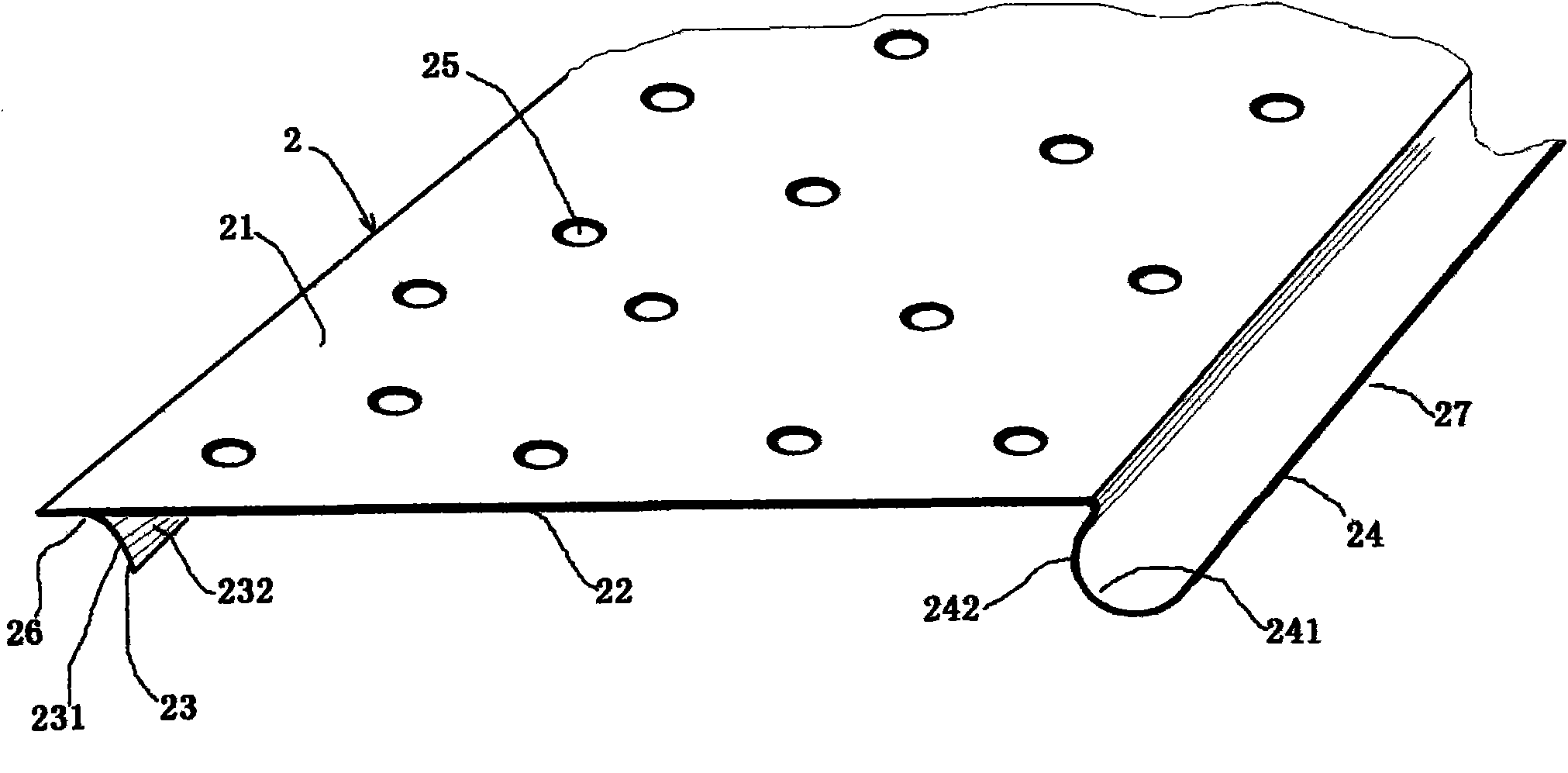

[0024] Embodiment 1: as figure 1 and figure 2 As shown, a geothermal floor includes a decorative surface plate 1 and a base plate 3 and a heat conduction medium 2 arranged between the decorative surface plate and the base plate, such as image 3 As shown, the heat conduction medium 2 is flat and long as a whole, the heat conduction medium 2 is an aluminum alloy profile and the upper and lower surfaces of the heat conduction medium have a plurality of second through holes 25 passing through the upper and lower surfaces; the heat conduction medium 2 includes a heat conduction medium upper surface 21, a heat conduction medium The lower surface of the medium 22, the left side 26 of the heat-conducting medium, and the right side 27 of the heat-conducting medium, wherein the left side 26 of the heat-conducting medium and the right side 27 of the heat-conducting medium each form an arc-shaped fold bent in the direction of the lower surface 22 of the heat-conducting medium , the cur...

Embodiment 2

[0025] Embodiment 2: as Figure 4 and Figure 5 As shown, a geothermal floor combination structure includes a first geothermal floor 5 and a second geothermal floor 6, the right side of the first geothermal floor 5 and the left side of the second geothermal floor 6 are connected to each other through a lock, wherein, The fourth contact surface 241 on the heat transfer medium 2 on the right side of the first geothermal floor 5 is surrounded by the second contact surface 231 on the heat transfer medium 2 on the left side of the second geothermal floor 6 to form a relatively closed section. The second cavity 7; as Figure 5 As shown, the second cavity 7 is provided with a strip-shaped heat source carrier 10, and the heat source carrier 10 of the present invention is a soft water pipe 8 for hot water to pass through; the outer surface of the soft water pipe 8 and the second contact surface 231 and the fourth contact surface The close contact of the surfaces 241 is conducive to t...

Embodiment 3

[0026] Embodiment 3: as Figure 4 and Figure 6 As shown, a geothermal floor combination structure includes a first geothermal floor 5 and a second geothermal floor 6, the right side of the first geothermal floor 5 and the left side of the second geothermal floor 6 are connected to each other through a lock, wherein, The fourth contact surface 241 on the heat transfer medium 2 on the right side of the first geothermal floor 5 is surrounded by the second contact surface 231 on the heat transfer medium 2 on the left side of the second geothermal floor 6 to form a relatively closed section. The second cavity 7; as Figure 6As shown, the second cavity 7 is provided with a strip-shaped heat source carrier 10, and the heat source carrier 10 of the present invention is a heating cable 9; the outer surface of the heating cable 9 is in close contact with the second contact surface 231 and the fourth contact surface 241 , which is conducive to the rapid transfer of heat to the floor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com