Unsaturated polyester resin for sheet or bulk molding compound and preparation method thereof

A mass molding compound and polyester resin technology, which is applied in the field of polymer material preparation, can solve the problems of high requirements on weather resistance and the inability of resin to meet the surface finish of molded products, and achieves high structural regularity, high finish and heat resistance. The effect of increasing the brightness and brightness of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

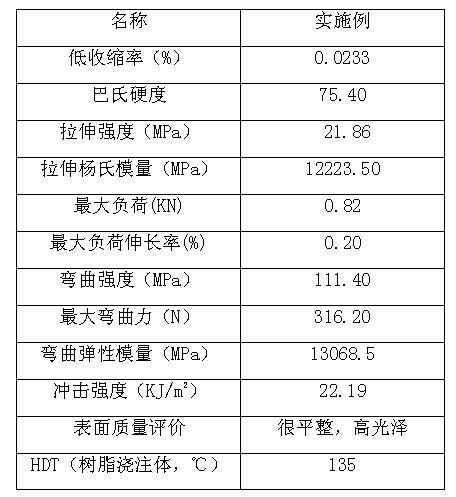

Examples

preparation example Construction

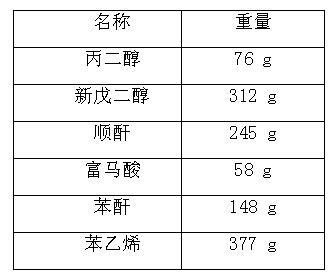

[0017] A preparation method of unsaturated polyester resin for sheet or bulk molding compound, comprising the following steps: putting propylene glycol, neopentyl glycol, maleic anhydride and fumaric acid into a device with heating and stirring in proportion, and feeding Under nitrogen protection, stir and heat up to effluent, control the temperature of the distillation head at 95-105°C and the reaction temperature at 180-190°C until the acid value is 70-80 mg KOH / g, increase the reaction temperature to 190-210°C until the acid value is less than 30 mg After KOH / g, cool down to 150°C, pour into a solution containing styrene and a polymerization inhibitor for dilution, and keep the dilution temperature at 60-80°C.

[0018] The inventor obtained a kind of unsaturated polyester resin for sheet / bulk molding compound (SMC / BMC) with high brightness and excellent weather resistance and its preparation method by improving the synthesis process and formula. The activity of the product a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com