Process for cutting silicon chip by using steel wire with diameter of 0.11 millimeter

A cutting process and steel wire technology, which is used in the process of cutting silicon wafers with a steel wire with a diameter of 0.11mm, to achieve the effect of reducing cutting loss, reducing cutting loss and improving the quality of cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

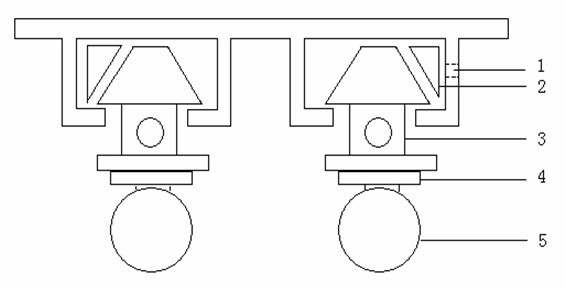

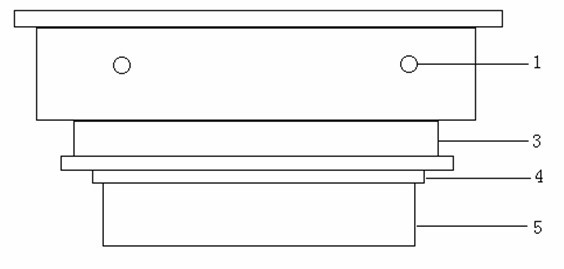

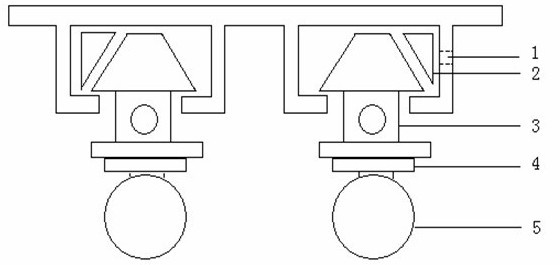

Image

Examples

Embodiment Construction

[0018] Specific examples are given below to further illustrate how the present invention is realized.

[0019] 1. The main equipment and raw materials of this embodiment are as follows:

[0020] Multi-wire cutting machine model: 442D; raw material: zone-melted (CZ) silicon single crystal, the cutting specification of this example is 3 inches thick silicon wafers with a thickness of 300um, the following is the production method and details of using 0.11mm diameter steel wires for silicon wafer cutting Process:

[0021] (1) Mortar configuration: The operator will dry the corundum, the drying temperature is 40-70 degrees, and the drying time is 20-60 minutes. This example uses 40 minutes. Calculate the amount of cutting fluid and emery according to the ratio (in this example, the mass ratio is cutting fluid: emery = 1:0.9), weigh them, and prepare the mortar in the mixing tank. The mixing time is 6-24 hours. This example uses 12 Hour.

[0022] (2) Orientation and stick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com