Rotating tyre traveling driving device of tube mill cylinder body

A walking drive, tube mill technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high technical requirements of operators, poor safety and reliability, difficult rotation, etc. Reliable effect of stability and cylinder rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

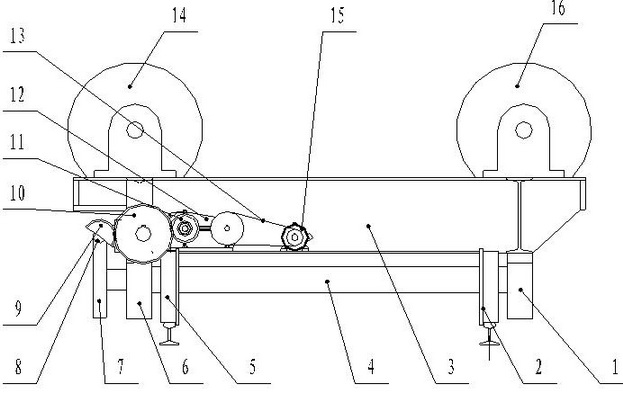

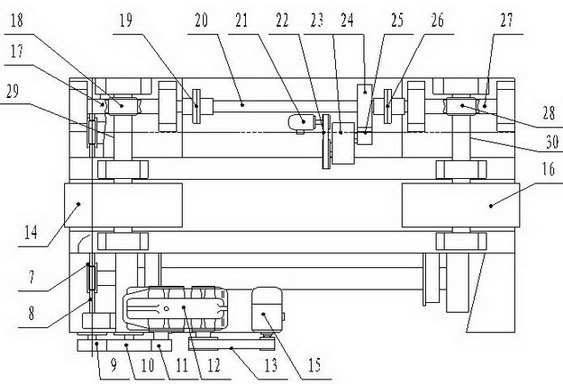

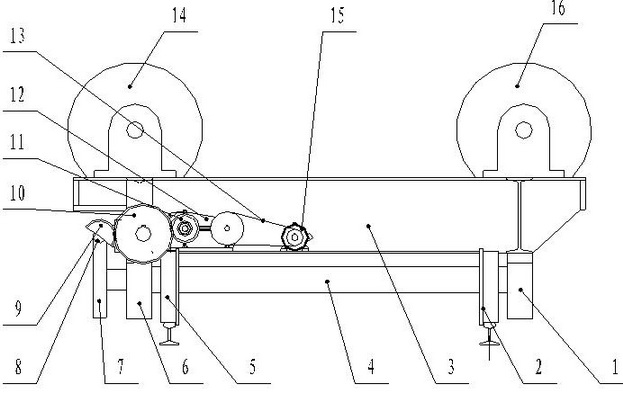

[0018] The tube mill cylinder rotating tire traveling driving device of the present invention is mainly composed of a vehicle frame 3, a traveling driving device, a roller body assembly and a roller driving device. The vehicle frame 3 is a frame structure welded by multiple pieces of section steel. It is the installation basis for other devices and assemblies. Walking driving device is located at the front side of vehicle frame 3, and roller body assembly is located at the middle part of vehicle frame 3, and the roller driving device linking to each other with roller body assembly is located at the rear side of vehicle frame 3. The walking driving device is mainly composed of I motor 15, I belt transmission 13, I speed reducer 12, I driving gear 11, intermediate gear 10, I driven gear 9, I worm screw 8, I worm gear 7, left shaft seat 6 , the left dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com