Preparation method of spherical catalyst carrier with magnetic anisotropy

A technology of catalyst carrier and magnetic anisotropy, which is applied in the direction of catalyst carrier, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor high temperature resistance, low residual magnetism, weak magnetism, etc., and achieve the recovery effect Good, low cost, strong magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. α-Fe with a magnetic core size of 0.1 μm 2 o 3 Add it into the aluminum sol, mechanically stir to disperse the magnetic nucleus evenly in the aluminum sol, and place it in the refrigerator to cool to minus 5°C. The magnetic nucleus accounts for 10% of the total mass of the magnetic nucleus and the aluminum sol, and the mass of the aluminum element in the aluminum sol The content is 10%.

[0024] b. Configure a 1mol / l hexamethylenetetramine solution, cool it to minus 5°C, then add it dropwise to the aluminum sol containing the magnetic nucleus, stir evenly, the molar ratio of Al to hexamethylenetetramine in the sol It is 1:1.

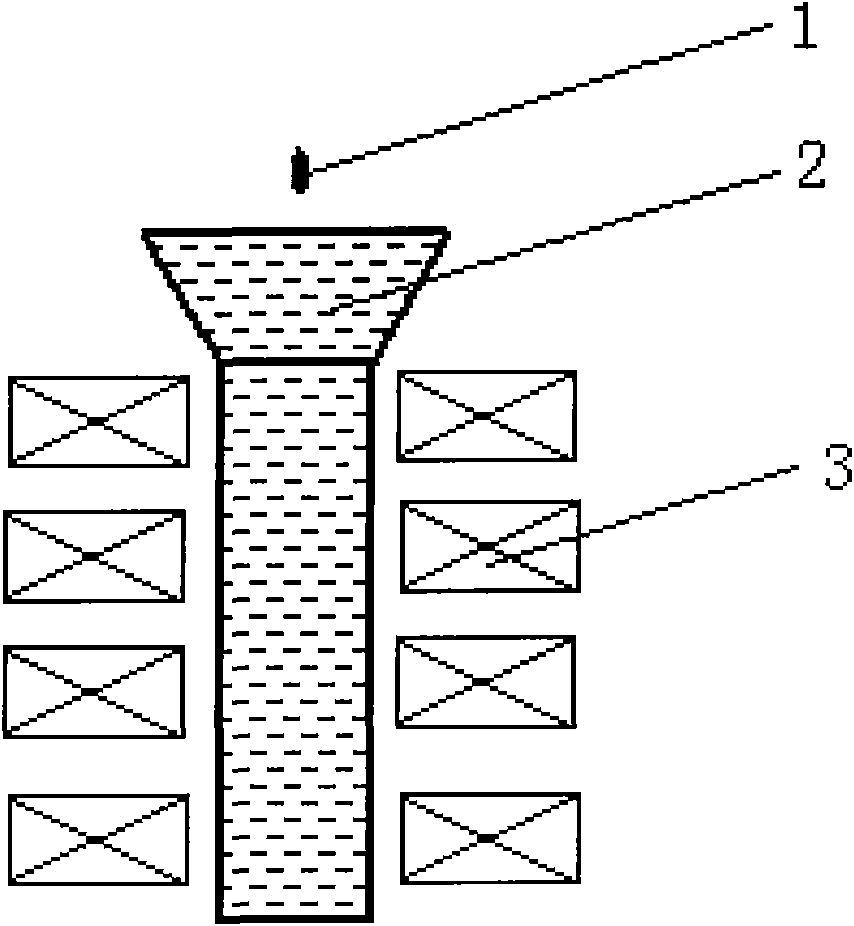

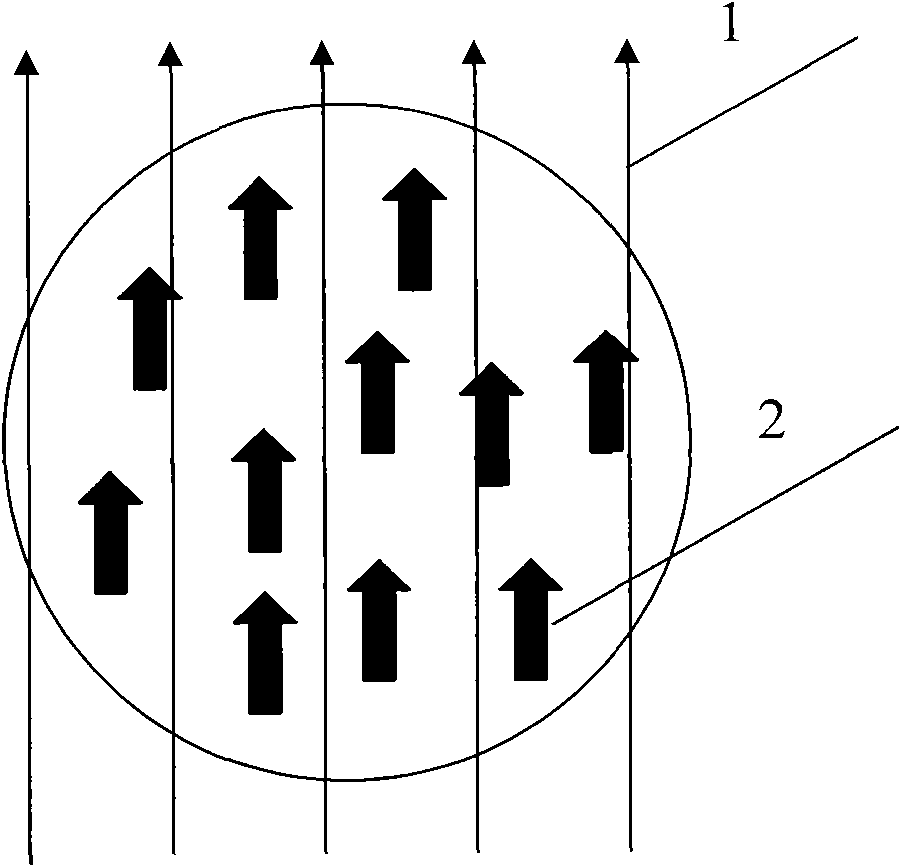

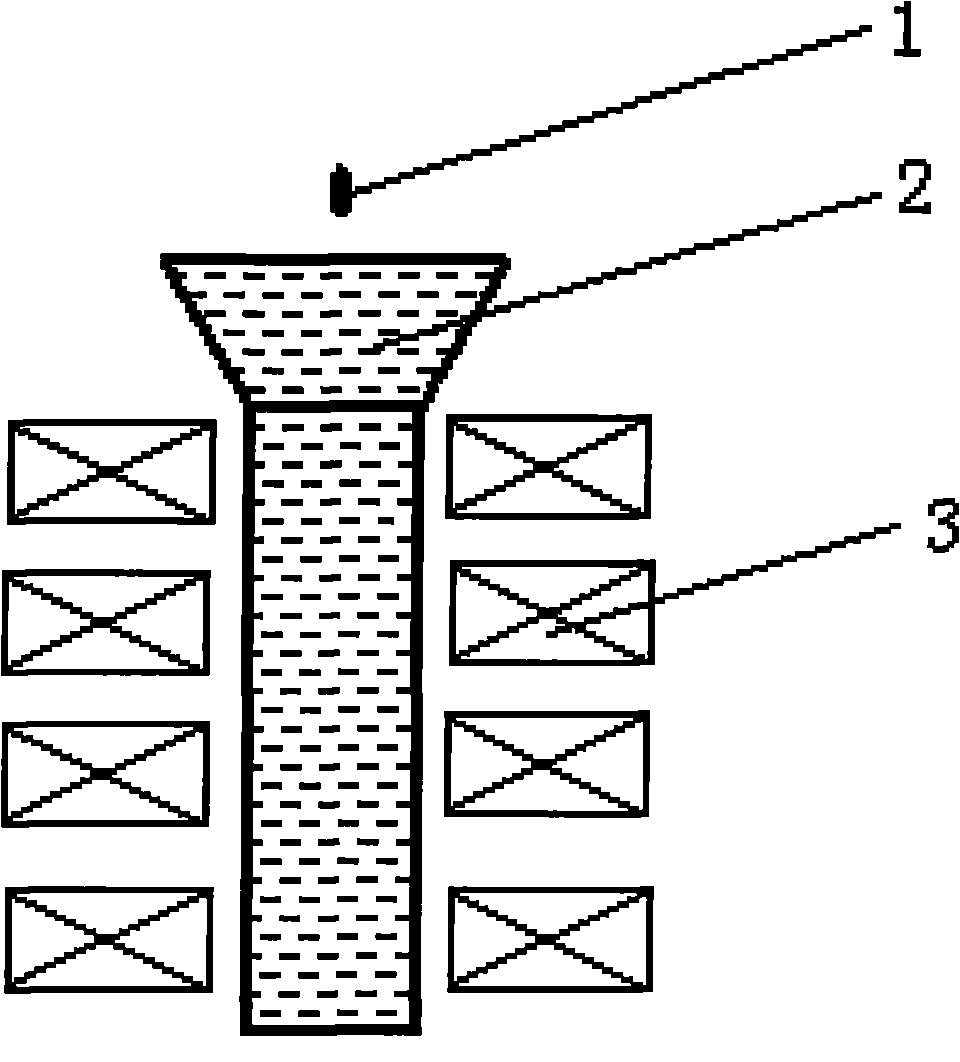

[0025] c. Drop the sol obtained in step b) into a magnetic field oil column forming device with a magnetic field strength of 0.2T and an oil column temperature of 90°C. After forming for 120 minutes, separate the formed pellets, then age at 120°C for 5 hours, and wash Afterwards, it was dried at 80°C for 5 hours, and then calcined at 500°C f...

Embodiment 2

[0028] a. Gamma-Fe with a magnetic core size of 10 μm 2 o 3 Add it into the aluminum sol, stir mechanically to evenly disperse the magnetic core in the aluminum sol, and place it in the refrigerator to cool to minus 3°C. The magnetic core accounts for 18% of the total mass of the magnetic core and the aluminum sol, and the mass of the aluminum element in the aluminum sol The content is 15%.

[0029] b. Prepare a 1mol / l urea solution, cool it to minus 5°C, then add it dropwise into the aluminum sol containing the magnetic core, and stir evenly. The molar ratio of Al and hexamethylenetetramine in the sol is 4:1.

[0030] c. Drop the sol obtained in step b) into a magnetic field oil column forming device with a magnetic field strength of 0.5T and an oil column temperature of 95°C. After forming for 100 minutes, separate the formed pellets, then age at 140°C for 5 hours, and wash Afterwards, it was dried at 80°C for 10 hours, and then calcined at 600°C for 6 hours to obtain a ma...

Embodiment 3

[0033] a. Fe with a magnetic core size of 1 μm 3 o 4 Add it into the aluminum sol, stir mechanically to evenly disperse the magnetic core in the aluminum sol, and put it in the refrigerator to cool to minus 5°C. The magnetic core accounts for 25% of the total mass of the magnetic core and the aluminum sol, and the mass of the aluminum element in the aluminum sol The content is 7%.

[0034] b. Configure a 0.5mol / l hexamethylenetetramine solution, cool it to minus 5°C, then add it dropwise to the aluminum sol containing the magnetic core, stir evenly, the mole of Al and hexamethylenetetramine in the sol The ratio is 2.5:1.

[0035] c. Drop the sol obtained in step b) into the magnetic field oil column forming device, the magnetic field strength is 1.2T, the oil column temperature is 90°C, after forming for 120min, separate the formed pellets, then age at 140°C for 5h, and wash Afterwards, it was dried at 80°C for 10 hours, and then calcined at 400°C for 6 hours to obtain a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com