Oral cancer nano vaccine and structuring method thereof

A tumor vaccine and nano-vaccine technology, which is applied in the field of tumor immunotherapy, can solve the problems of restricting the oral application of protein/peptide vaccines, reducing the bioavailability of tumor vaccines, and low absorption rate of particulate antigen substances, and amplifying the anti-tumor immunity of tumor vaccines. effect, improve bioavailability, improve the effect of introduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

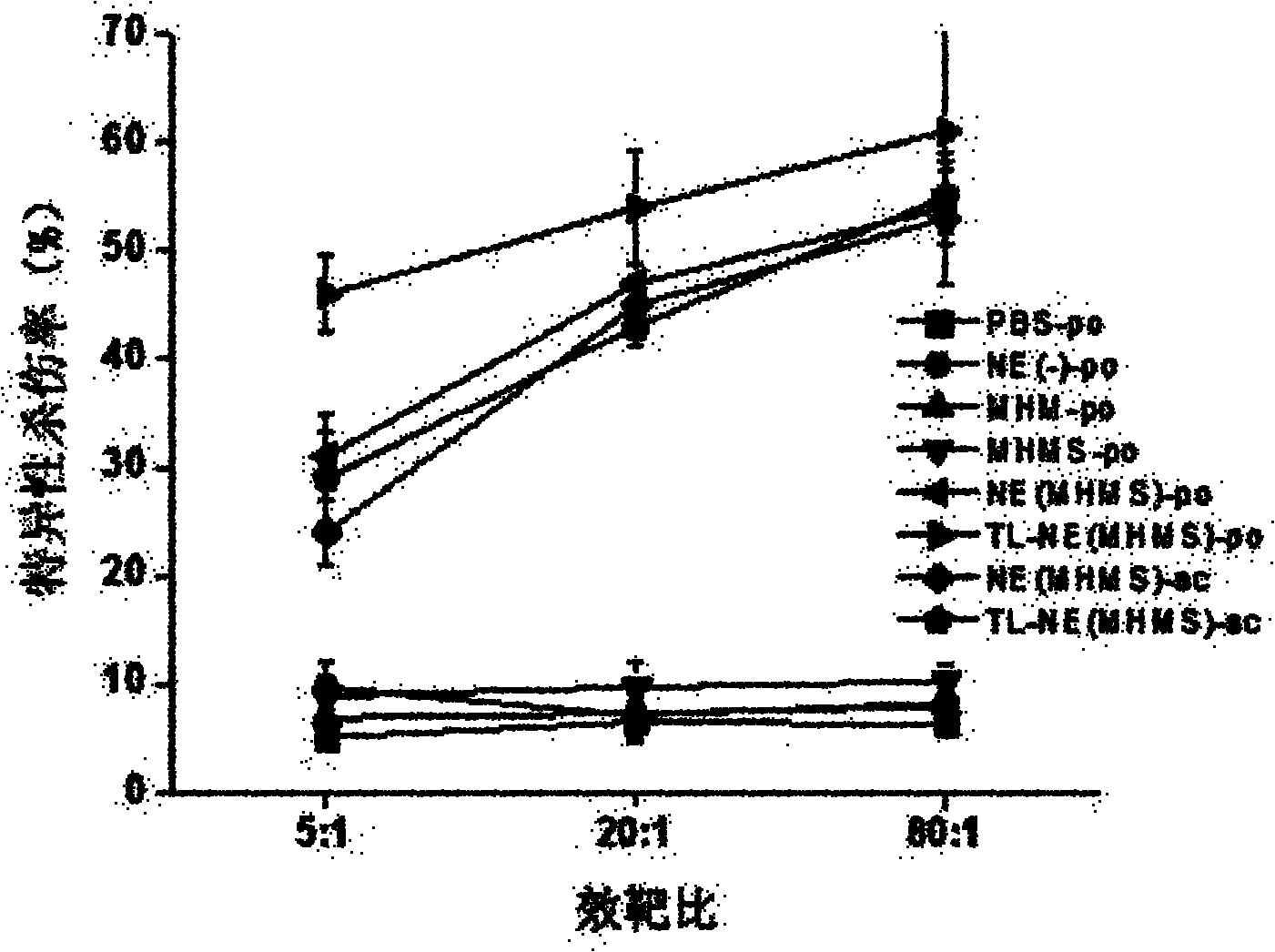

Examples

Embodiment 1

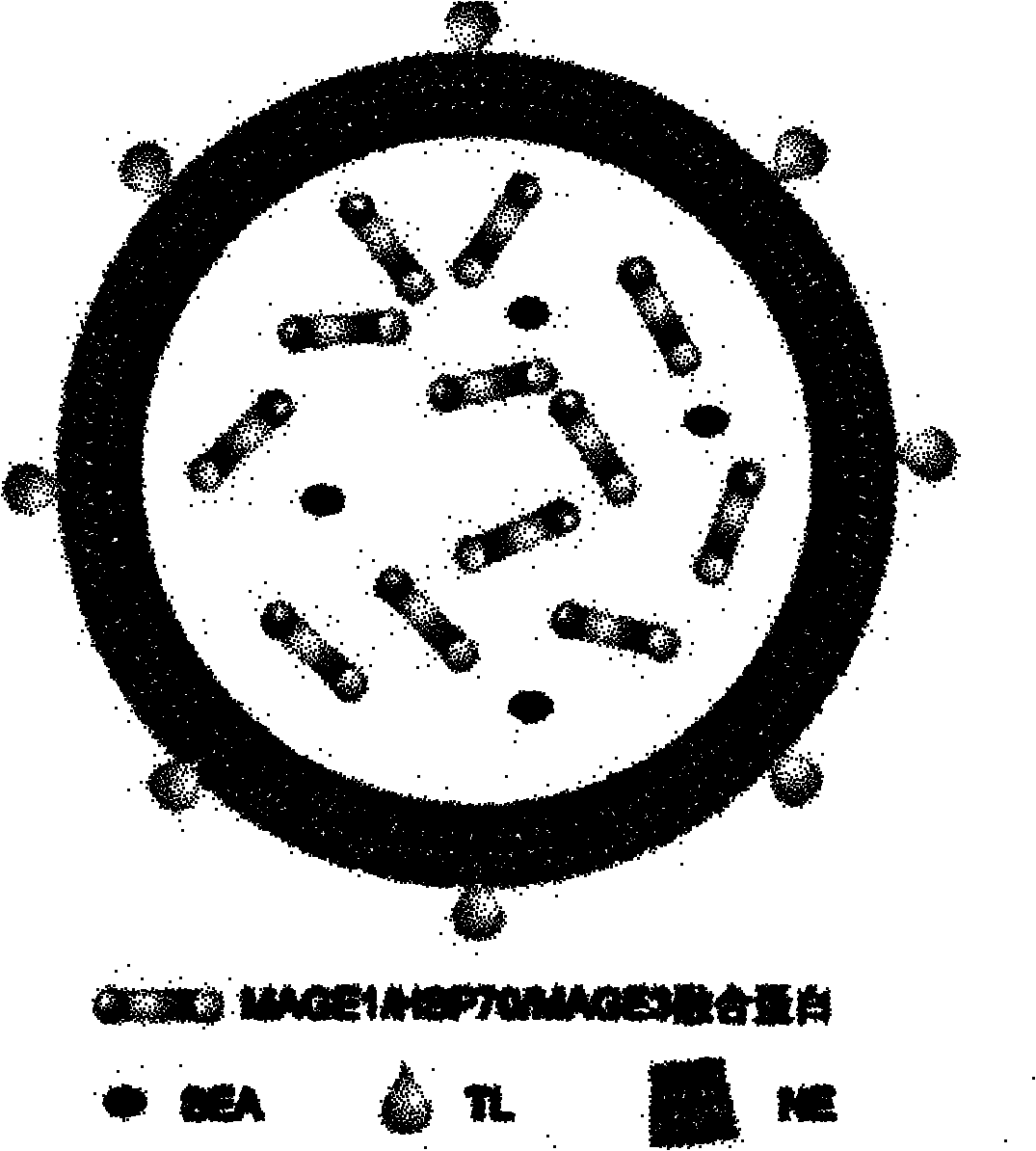

[0031] (1) Preparation of water-in-oil nanoemulsion tumor vaccine

[0032] Mix 1.0 mg of composite antigen (MAGE1 / HSP70 / MAGE3 and SEA at a molar ratio of 100:1), Span-20, Pluronic188 and 0.6 mL of soybean oil, adjust the total volume to 2.5 mL with double distilled water, and mix well to obtain oil Then, under 3000rpm magnetic stirring, the oil phase was added dropwise to 7.5mL of double-distilled water and water phase, and then moved to a vacuum high-speed shear emulsifier, under 0.7KPa vacuum, 23000 rpm under high-speed shear for 40min , the temperature was controlled below 80°C; then moved to an ice bath and ultrasonicated at 40KHz for 5 minutes, repeated ultrasonication three times, dialyzed to remove free protein, and sterilized by filtration with a 0.22μm filter membrane, and stored at 4°C for later use to obtain water-in-oil nano Emulsion tumor vaccine; the mass percentage concentration of Span-20 in the oil phase is 8%, and the mass percentage concentration of Pluronic...

Embodiment 2

[0038] (1) Preparation of water-in-oil nanoemulsion tumor vaccine

[0039]Mix 0.5 mg of composite antigen (MAGE1 / HSP70 / MAGE3 and SEA at a molar ratio of 50:1), Span-20, Pluronic188 and 0.6 mL of soybean oil, adjust the total volume to 1 mL with double distilled water, and mix well to obtain an oil phase ; then under 3000rpm magnetic stirring, the oil phase was added dropwise to the 3mL double-distilled water phase, and then moved to the vacuum high-speed shear emulsifier, under 1KPa vacuum, high-speed shear 50min under the condition of 20000 rpm, temperature control Below 80°C; then move to an ice bath for 30KHz ultrasound for 8 minutes, repeat the ultrasound three times, dialyze to remove free protein, filter and sterilize with a 0.22μm filter membrane, store at 4°C for later use, and obtain a water-in-oil nanoemulsion tumor vaccine ; The mass percentage concentration of Span-20 in the oil phase is 5%, and the mass percentage concentration of Pluronic188 is 20%;

[0040] (2)...

Embodiment 3

[0044] (1) Preparation of water-in-oil nanoemulsion tumor vaccine

[0045] Mix 1.5 mg of composite antigen (MAGE1 / HSP70 / MAGE3 and SEA at a molar ratio of 150:1), Span-20, Pluronic188 and 0.6 mL of soybean oil, adjust the total volume to 4 mL with double distilled water, and mix well to obtain an oil phase Then under 3000rpm magnetic stirring, the oil phase is added dropwise in the 12mL double-distilled water phase, and then moved to the vacuum high-speed shear emulsifier, under 0.5KPa vacuum, high-speed shear 30min under 25000 rpm conditions, temperature Control the temperature below 80°C; then move to an ice bath for 50KHz ultrasound for 3 minutes, repeat the ultrasound three times, dialyze to remove free protein, filter and sterilize with a 0.22μm filter membrane, store at 4°C for later use, and obtain a water-in-oil nanoemulsion tumor Vaccine; the mass percent concentration of Span-20 in the oil phase is 10%, and the mass percent concentration of Pluronic188 is 15%;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com