Oil shale retorting method as well as dynamic grate type retort furnace for realizing same and application thereof

A technology for oil shale and dry distillation furnace, which is applied in the field of dry distillation of oil shale, can solve problems such as waste, and achieve the effects of reducing separation cost, heat loss and extraction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

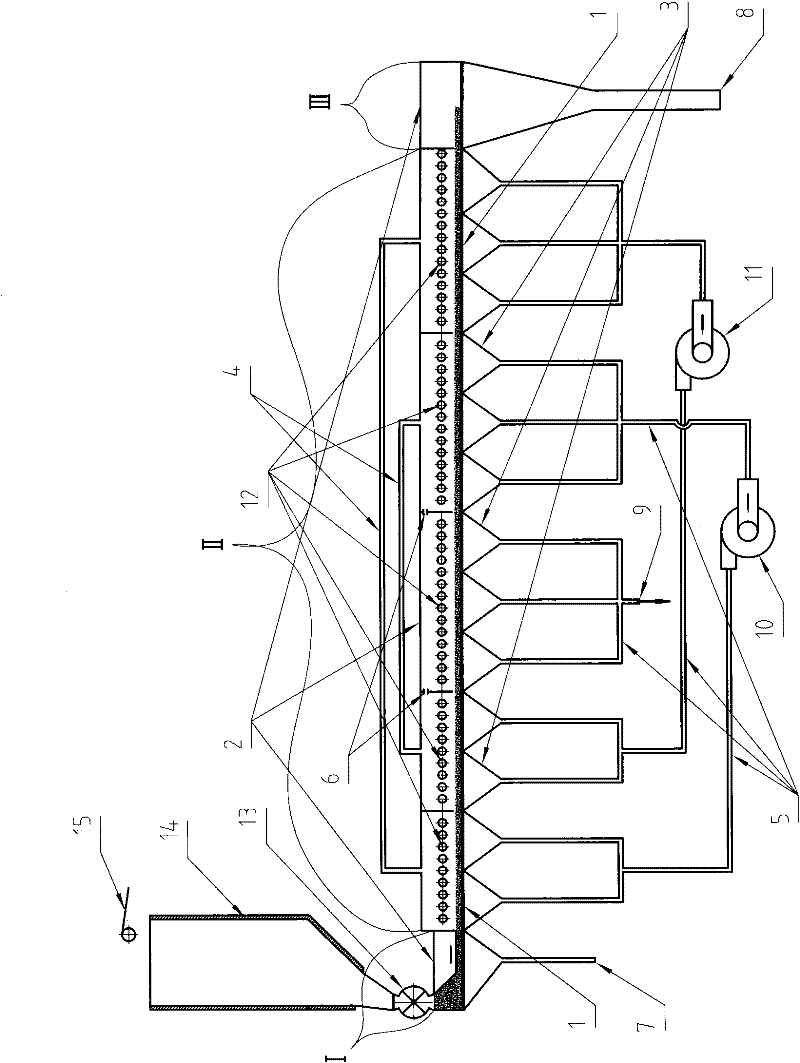

[0067] Example 1, as figure 1 shown.

[0068] exist figure 1 In the example 1 shown, the moving grate type retort furnace is divided into three sections: the first section is the feed section, the second section is the dry distillation section, and the third section is the discharge section of the oil shale semi-coke. When the moving grate rotates on a circular track, its first and third sections are connected end-to-end. At this time, its structural treatment can refer to related existing technologies, including rotary hearth furnaces, ring coolers, etc. ;When the moving grate is dragged by the chain for translational movement, it and the chain also have a no-load return section connected end to end, but it is not shown in the figure. In order to facilitate sealing, it is recommended that this return section also If it is fully enclosed, at this time, its structural treatment can refer to related existing technologies, including chain grate machines and so on.

[0069] e...

Embodiment 2

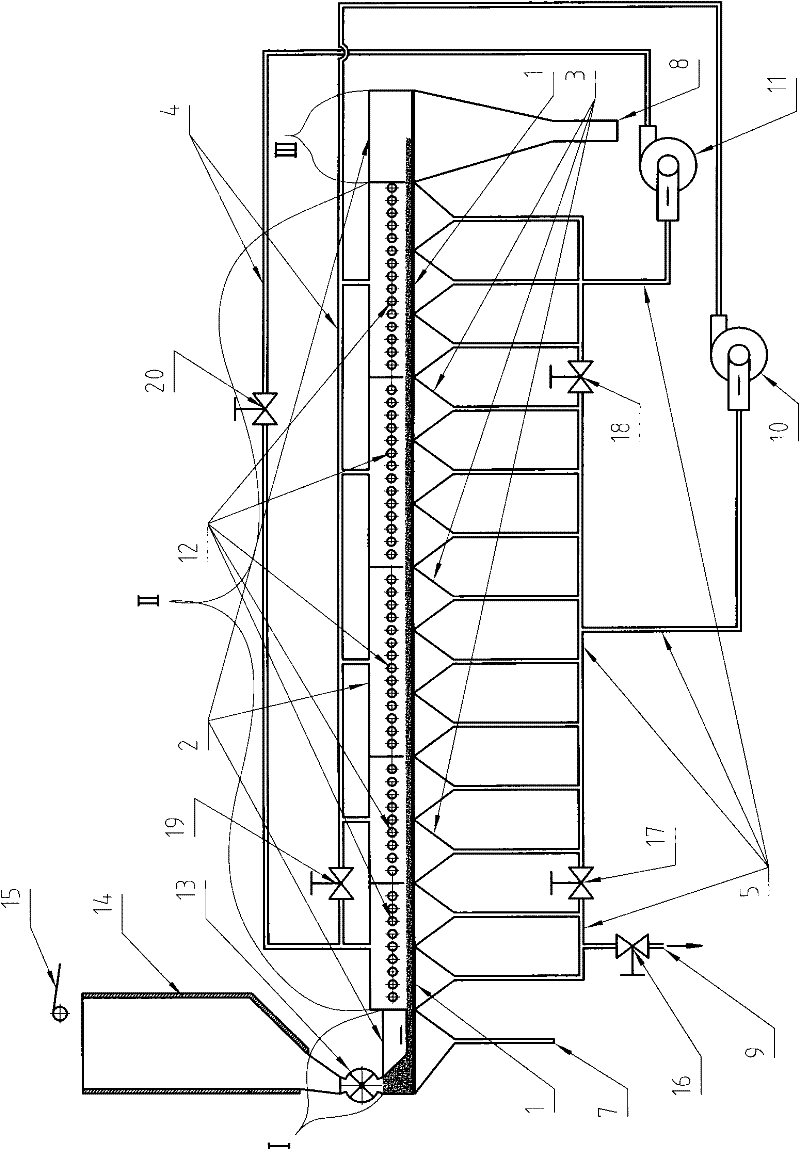

[0073] Example 2, as figure 2 shown.

[0074] This embodiment is an improved solution based on Embodiment 1.

[0075] exist figure 2 In the illustrated embodiment 2, in addition to changing the communication relationship and direction of the pipes 5 and 4, valves 16, 17, 18, 19 and 20 are also added; at the same time, the air string hole 6 in the embodiment 1 is cancelled. ; the rest are the same as in Example 1.

[0076] By adjusting the opening of the valve 16, the outgoing amount of shale oil and gas can be adjusted; when the valves 17, 18, and 19 are opened, the valve 20 is closed and the operation of the fan 11 is stopped, and the single fan is in the circulating operation state; when After closing the valves 17, 18 and 19, opening the valve 20 and starting the fan 11, it enters the operation state of the double fan. The furnace gas is sent to the heating chamber on the far left. On the one hand, since the temperature of the raw oil shale that has just entered the f...

Embodiment 3

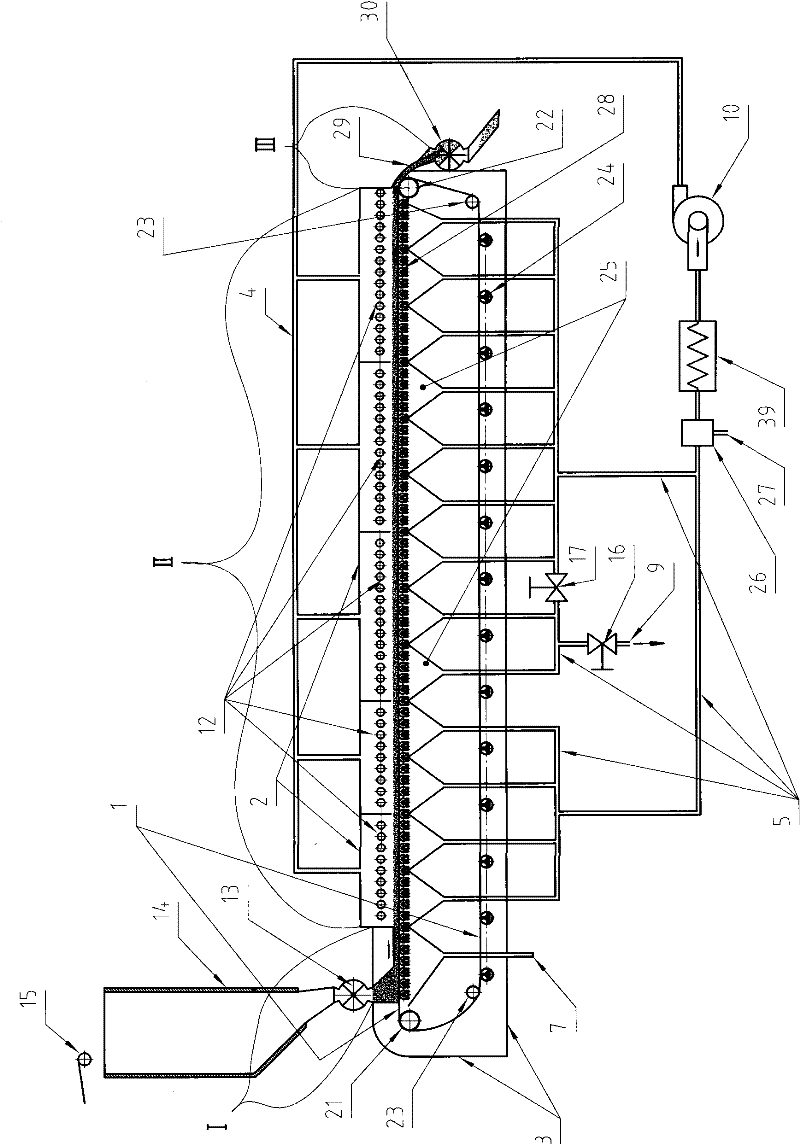

[0078] Example 3, as image 3 shown.

[0079] This embodiment has made great changes on the basis of the above-mentioned embodiment, and is mainly used to reflect the characteristics when the movable grate 1 has a chain structure.

[0080] In this embodiment, in addition to changing the communication relationship and direction of the pipes 4 and 5, the fan 11 is also eliminated. At the same time, a separator 26 for extracting a small amount of oil and water components from the circulating gas and a heat exchanger 39 for returning the temperature of the circulating gas to the original level are added. Of course, the "temperature return to the original level" mentioned here , does not rule out that the temperature has increased on the original basis, such as an increase of about 10%. At this time, the separated oil and water components can be discharged from the channel 27; the purpose is to make the concentration of the oil and vapor components in the circulating gas signific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com