Method for improving air tightness of investment casting aluminum processing equipment

A tooling gas and precision casting technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of unqualified air tightness, tooling pores, trachoma, etc., and achieve a simple and reliable process method. The effect of improving the qualification rate of tooling and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

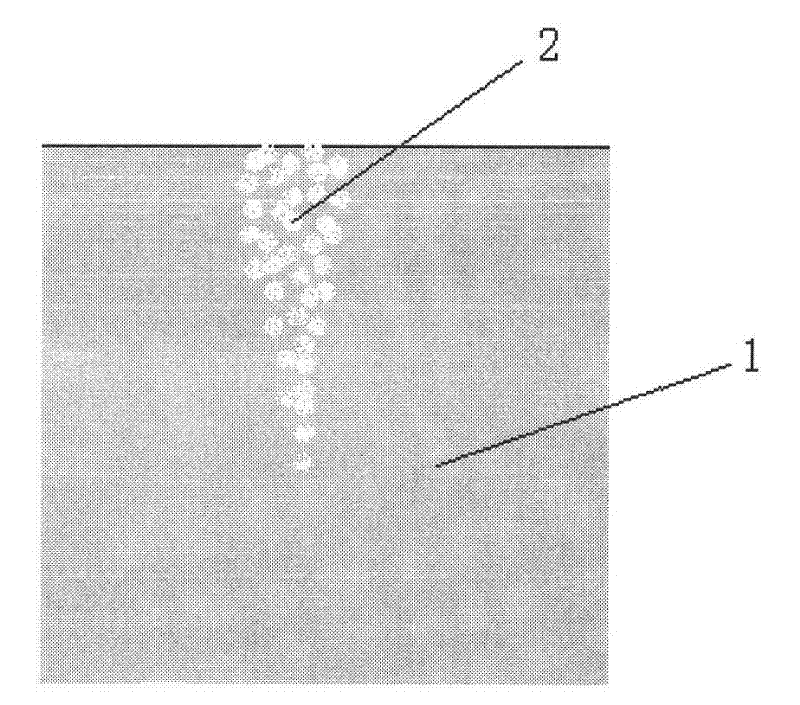

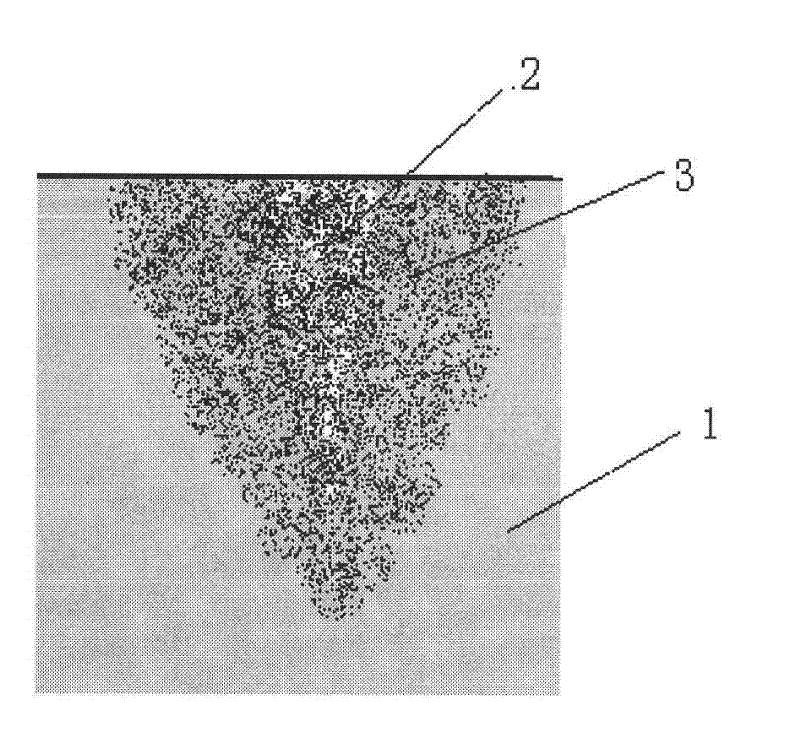

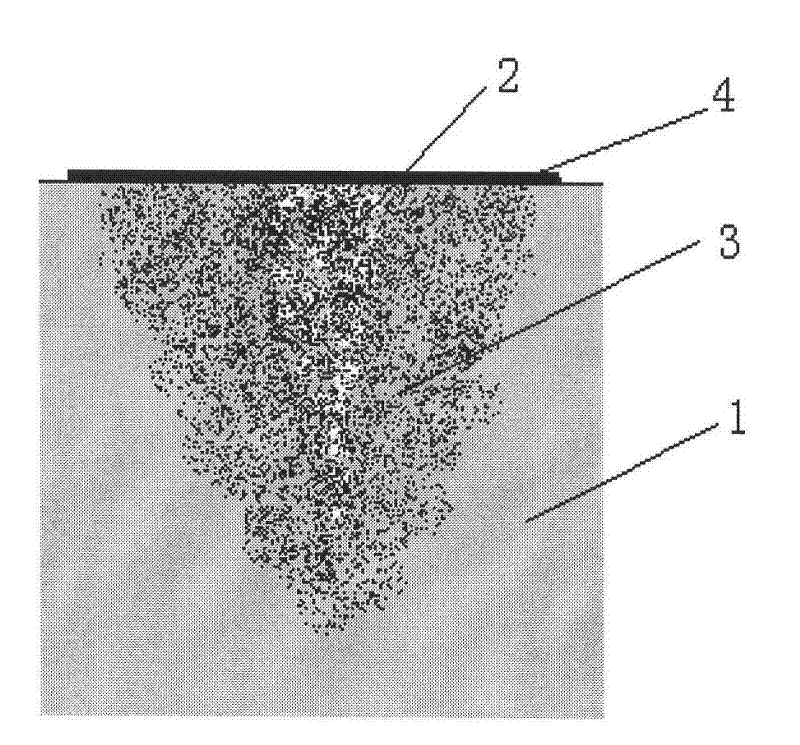

[0016] See attached picture, figure 1 It is a large-scale precision-cast aluminum tooling for manufacturing composite material parts for aircraft. The tooling was found to have local defects during inspection, which resulted in unqualified air tightness of the tooling and could not be delivered for production. The specific repair implementation plan is as follows:

[0017] 1. Surface cleaning:

[0018] First, remove the casting residue on the back of the air leaking part of the tooling to expose the true color of the metal and roughen it. The rougher the surface, the better; then use a cleaning agent to clean it repeatedly to ensure that it is oil-free and water-free, at least three times. Dry at room temperature for at least four hours or heat to 150°C for one hour.

[0019] 2. Brush penetrating agent

[0020] Penetrate with penetrant. First, heat the precision cast aluminum tooling to 60 ℃ ~ 80 ℃, keep it warm for at least 3 hours, then apply the penetrant on the back of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com