Tower feeding distributor

The technology of feed distributor and flow divider is applied in the field of anti-gas mist entrainment feed distributor, single tangential or double tangential feed distributor, which can solve the problem of large rising gas swirl and rising gas in the distributor. Fog entrainment, inability to distribute materials evenly, etc., to avoid uneven gas distribution, achieve highly uniform distribution, and avoid easy coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

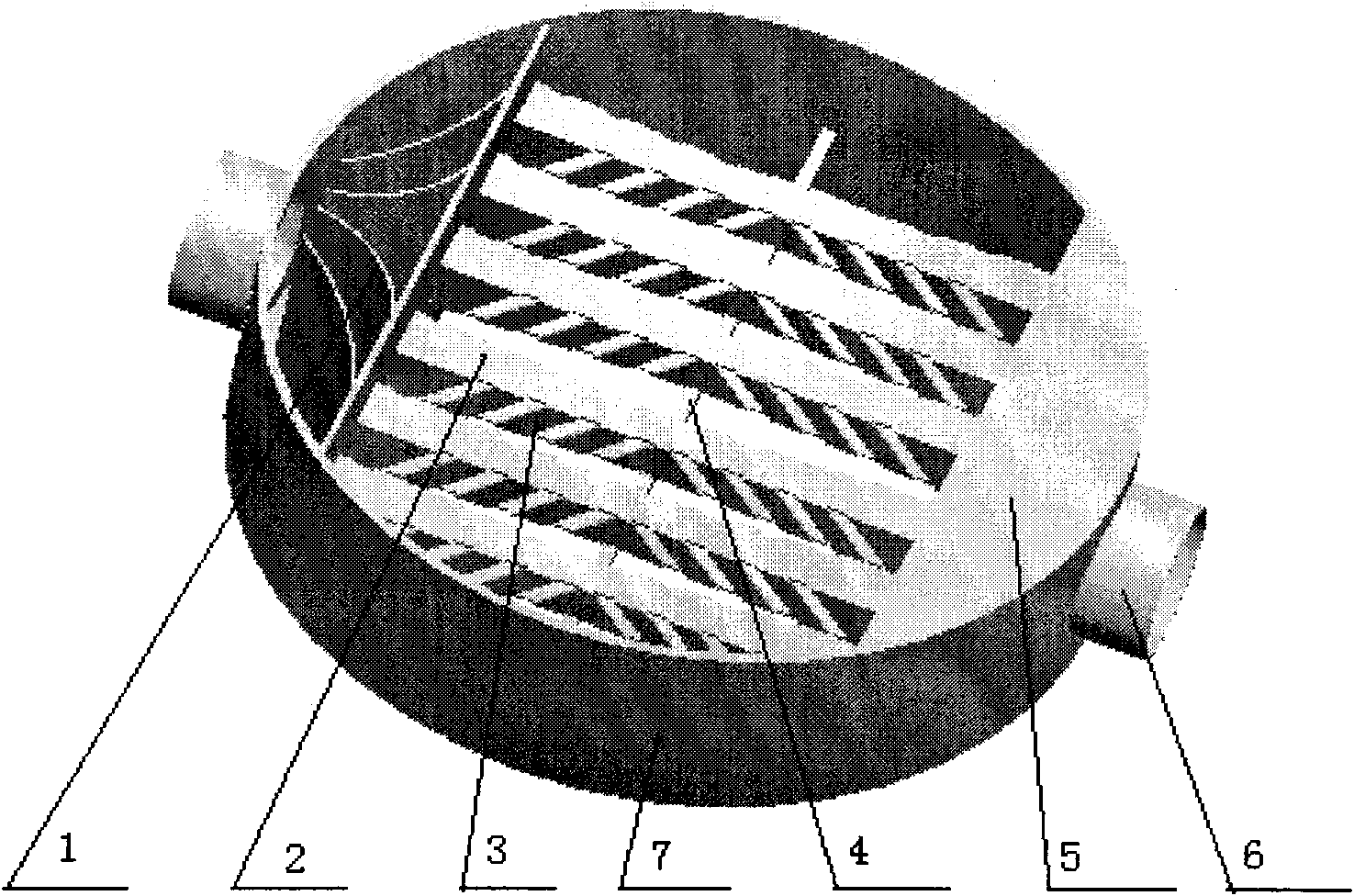

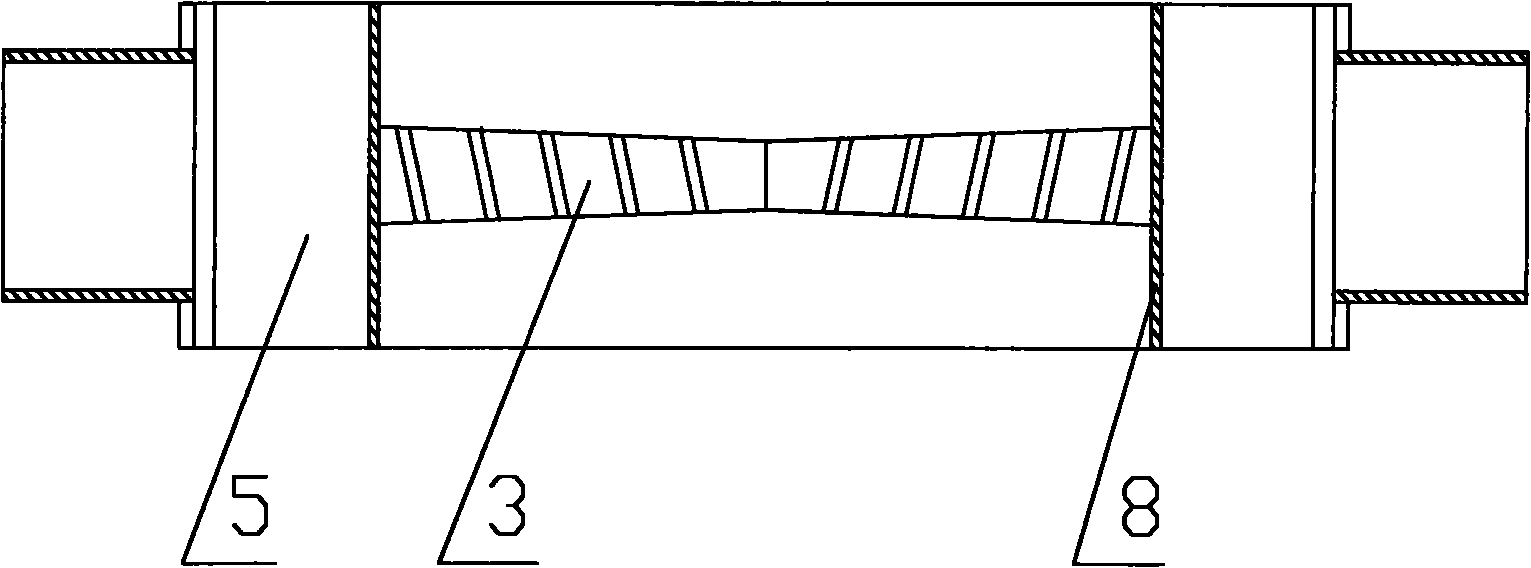

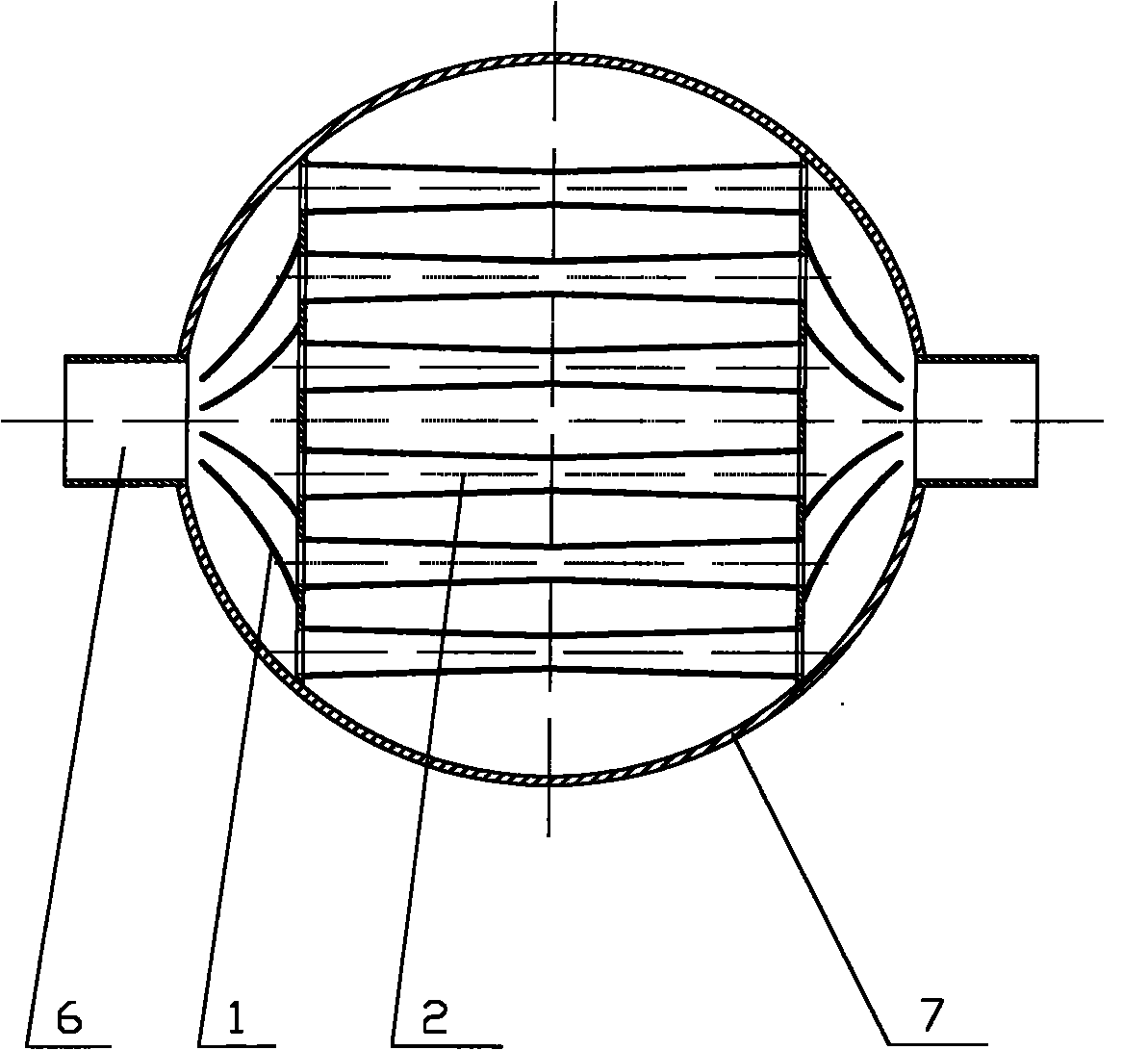

[0021] A novel feed distributor of the present invention is specifically a blade-type double tangential feed distributor, the basic structure of which includes a feed inlet 6, a deflector 1, a louver flow channel 2, blades 3, and a flow divider 5. like figure 1 As shown, the splitter 5 and the tower wall form a fan-shaped structure closed up and down, which is located between the feed port 6 and the louver flow channel 2, and communicates with the feed port 6 and the louver flow channel 2. The end of the flow plate 1 is fixed on the end plate 8 of the flow divider, and the upper and lower elevations are welded to the upper and lower cover plates of the flow divider to form several watersheds that are not connected to each other, such as figure 2 As shown; the louver flow channel 2 is a rectangular or circular channel whose flow area gradually decreases along the feeding direction, and the front end is fixed on the support end plate 8 of the splitter; the front end of the lou...

Embodiment 2

[0025] A novel feed distributor of the present invention is specifically a blade-type single tangential feed distributor, and its basic structure includes a feed inlet 6, a deflector 1, a louver flow channel 2, blades 3, and a flow divider 5, like Figure 4 shown. The structure of the flow divider 5 and the deflector 1 is the same as that of the embodiment 1. One end of the opening of the louver flow channel 2 faces the flow divider 5 , the top and bottom are closed, and the end is a closed structure, which is fixed on the support beam 4 . On both sides of the louver flow channel 2, multiple groups of blades 3 of different sizes are arranged in sequence from the inlet end, and the directions of the blades on both sides are staggered; Figure 5 shown. The specific positions, quantities and heights of the deflectors 1 and vanes 3 are determined by CFD simulation calculations according to the amount of feed gas-liquid, feed gas-liquid ratio, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com