Ganoderma sinensis mycelium anti-tumor polysaccharide component GS-C as well as preparation method and application thereof

A GS-C, anti-tumor technology, used in anti-tumor drugs, medical preparations containing active ingredients, drug combinations, etc., can solve problems such as molecular weight and purity of polysaccharides that are not involved, reduce the molecular weight range and increase polysaccharide content. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

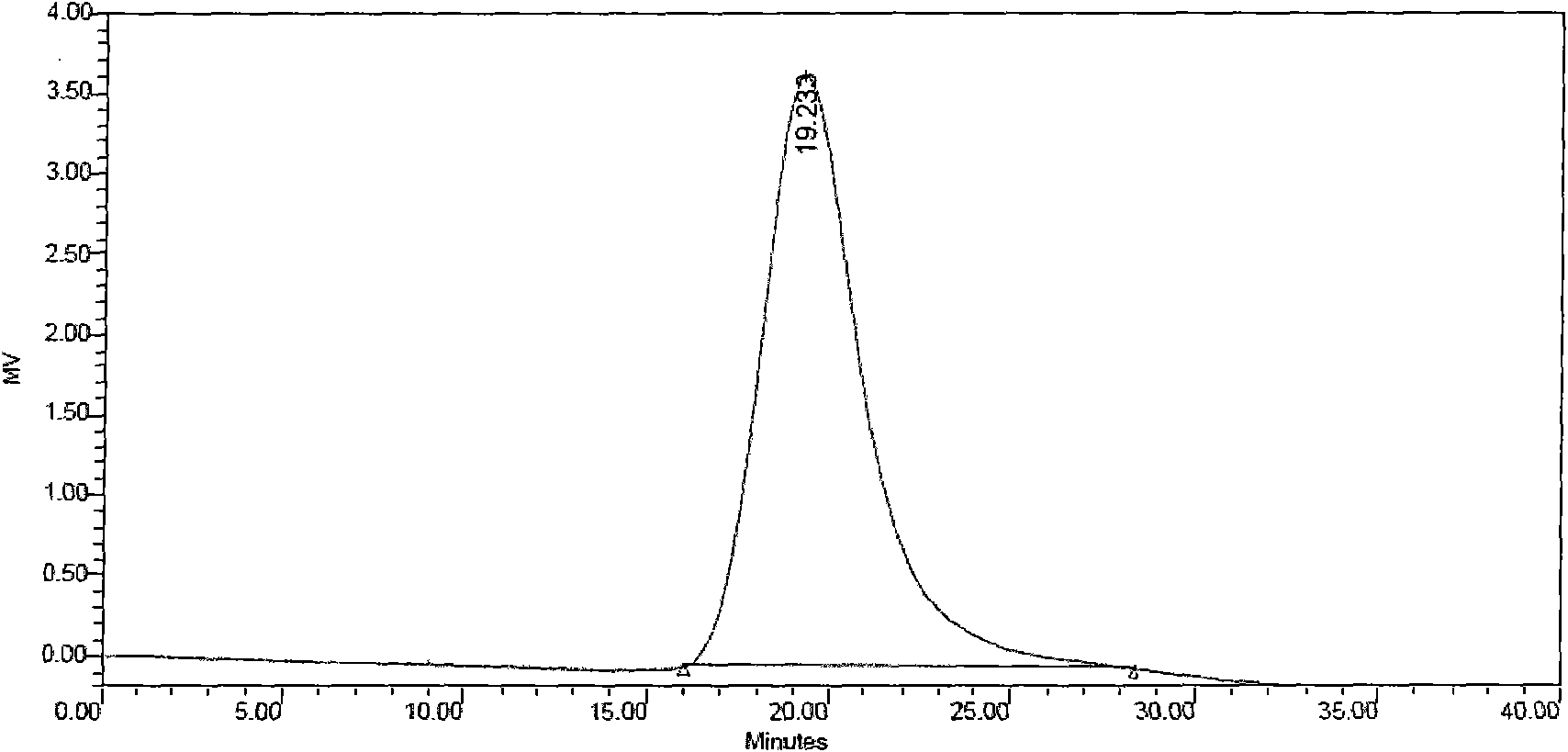

Image

Examples

Embodiment 1

[0054] Preparation of crude polysaccharide from Zizhi mycelium:

[0055] Zizhi liquid submerged fermentation liquid 1300L (the Zizhi liquid submerged fermentation liquid is obtained by the method described in Chinese patent 200710045369.4 "A Zizhi fermentation method and prepared Zizhi mycelium"), the mycelium is extracted with water for 1-3 hours, The extract was concentrated under reduced pressure, ethanol was added for precipitation, and the precipitated part was dried to constant weight to obtain 150 g of crude polysaccharide.

[0056] Ultrafiltration separation:

[0057] Dissolve 150g of the extract in 20 times deionized water, and ultrafilter it with a polyamide hollow cellulose ultrafiltration membrane with a molecular weight cut off of 10,000. The pressure is 0.1-0.3mPa. Preferably, collect the retentate, concentrate the liquid with a nanofiltration membrane with a molecular weight cut-off of 150, and freeze-dry to obtain 62.3 g of polysaccharides greater than 10,000 ...

Embodiment 2

[0062] Zizhi liquid submerged fermentation liquid 1300L (the Zizhi liquid submerged fermentation liquid is obtained by the method described in Chinese patent 200710045369.4 "A Zizhi fermentation method and prepared Zizhi mycelium"), the mycelium is extracted with water for 1-3 hours, The extract was concentrated under reduced pressure, ethanol was added for precipitation, and the precipitated part was dried to constant weight to obtain 150 g of crude polysaccharide.

[0063] Ultrafiltration separation:

[0064] Dissolve 150g of the extract in 30 times deionized water, and ultrafilter it with a polyamide hollow cellulose ultrafiltration membrane with a molecular weight cut-off of 30,000. The pressure is 0.1-0.3mPa, and the solution flow rate depends on the membrane to maintain good permeability Preferably, the retentate is collected, the liquid is concentrated with a nanofiltration membrane with a molecular weight cut-off of 200, and freeze-dried to obtain 60 g of polysaccharid...

Embodiment 3

[0069] Zizhi liquid submerged fermentation liquid 1300L (the Zizhi liquid submerged fermentation liquid is obtained by the method described in Chinese patent 200710045369.4 "A Zizhi fermentation method and prepared Zizhi mycelium"), the mycelium is extracted with water for 1-3 hours, The extract was concentrated under reduced pressure, ethanol was added for precipitation, and the precipitated part was dried to constant weight to obtain 150 g of crude polysaccharide.

[0070] Ultrafiltration separation:

[0071] Dissolve 150g of the extract in 20 times deionized water, and use a tubular ultrafiltration membrane made of sulfonated polysulfone with a molecular weight cut-off of 30,000 for ultrafiltration. The pressure is 0.1-0.3mPa. The rate is appropriate, collect the retentate, concentrate the liquid with a nanofiltration membrane with a molecular weight cut-off of 250, and freeze-dry to obtain 56.8 g of polysaccharides greater than 30,000 in the mycelia of Zizhi mycelium.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com