Petroleum coke powder combustion transporting device for improved industrial furnace

A petroleum coke powder and conveying device technology, which is applied in the direction of conveying bulk materials, conveyors, combustion methods, etc., can solve the problem of reducing the pressure of gas source conveying, and achieve the effect of reducing power consumption and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by way of implementation and accompanying drawings:

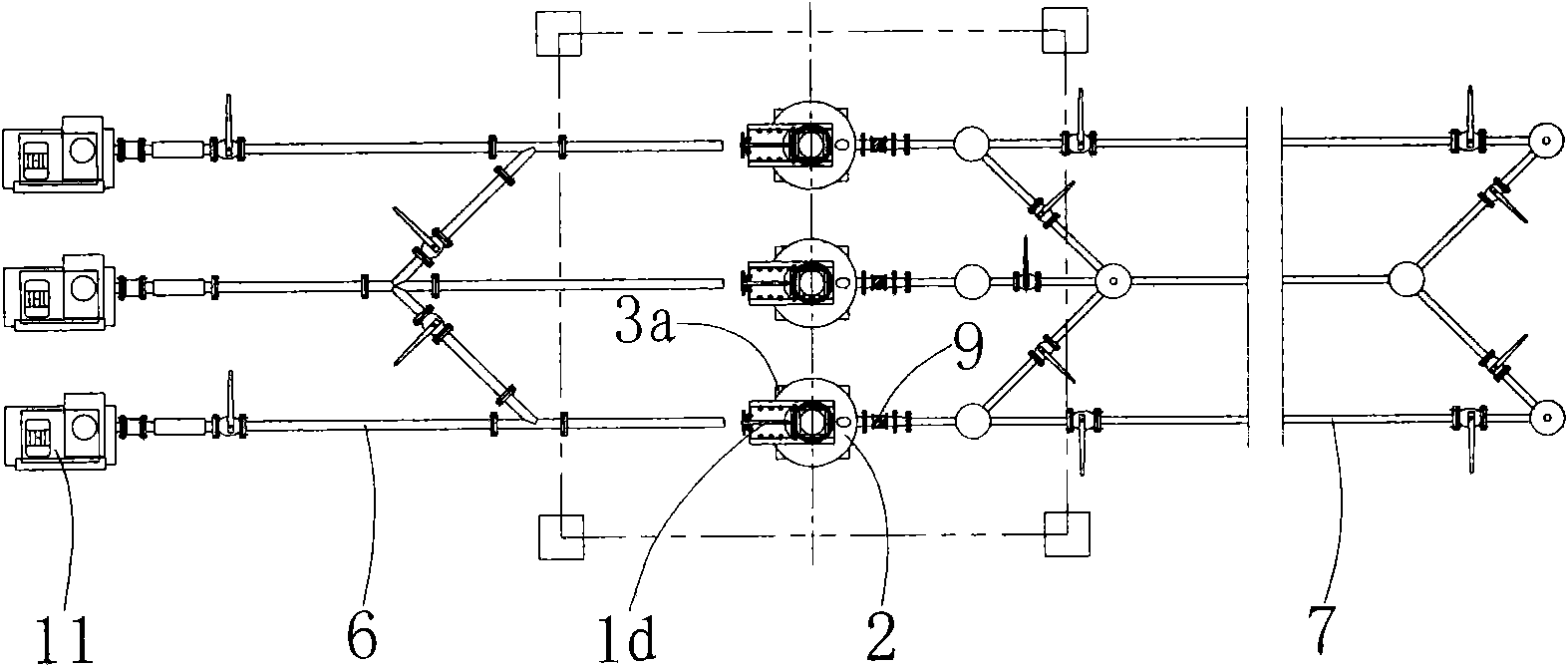

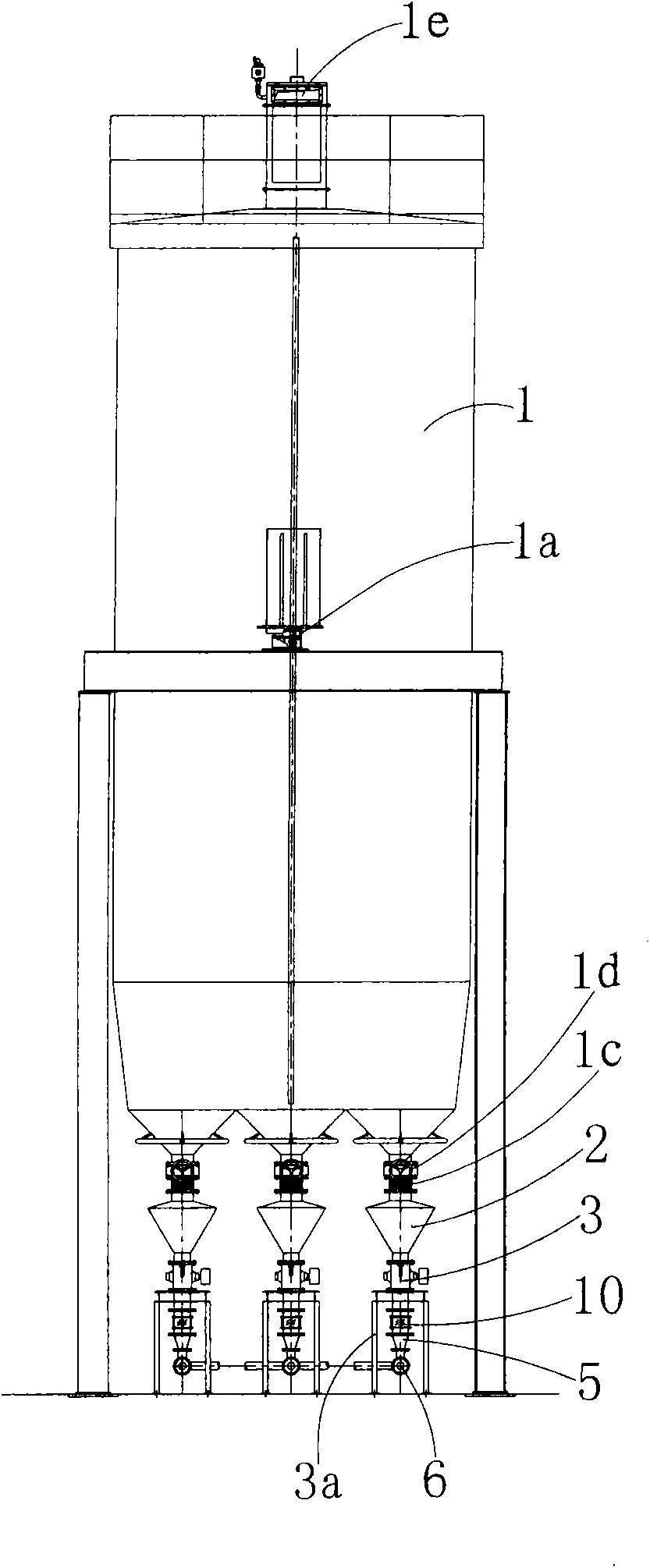

[0015] For the sake of succinct explanation, figure 2 Removed the silo 1 and its corresponding accessories, air pipe 2a, feeder controller 4, weighing controller 8, image 3 Removed filter 1g, feeder controller 4, weighing controller 8, blower 11.

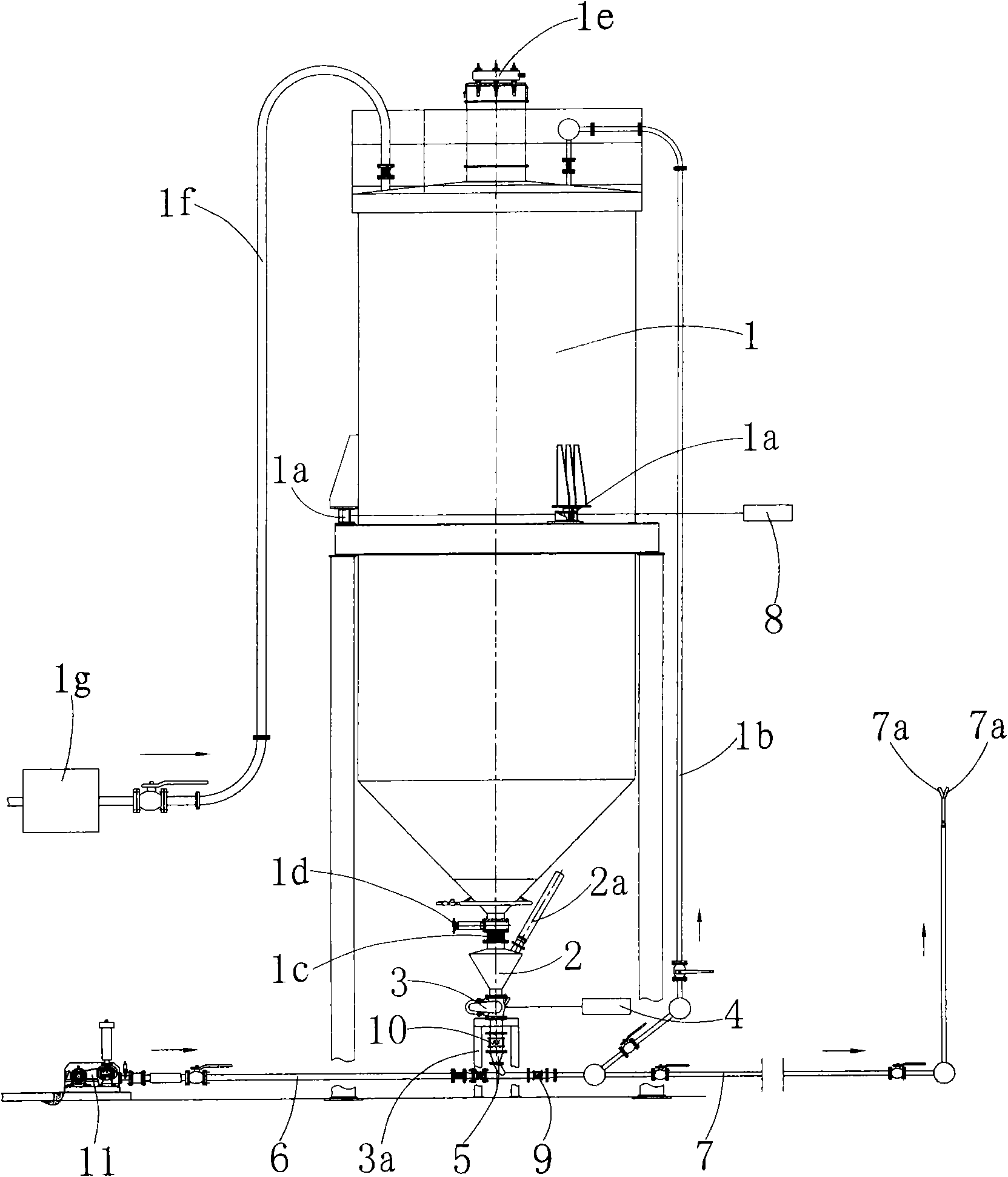

[0016] see figure 1 , the present invention provides an improved petroleum coke powder combustion conveying device for industrial kilns, which includes a silo 1, a ventilating balance chamber 2, a feeder 3, a feeder controller 4, a pneumatic fluidization chamber 5, a regular Compressed air delivery pipeline 6 and fuel delivery pipeline 7.

[0017] The silo 1 is used to temporarily store petroleum coke powder. The feed pipe 1f with a filter 1g is connected to the top of the silo 1. The upper end of the silo 1 is equipped with a dust collector 1e, and three load cells 1a are evenly distributed in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com