Bonding device, bonding method, and pressurization unit

A bonding device, a single technology, applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve problems such as deviation, inability to bond the substrate 12 and semiconductor components 14, and difficulty in moving, so as to prevent sintering reactions and delay heat from being conducted to Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

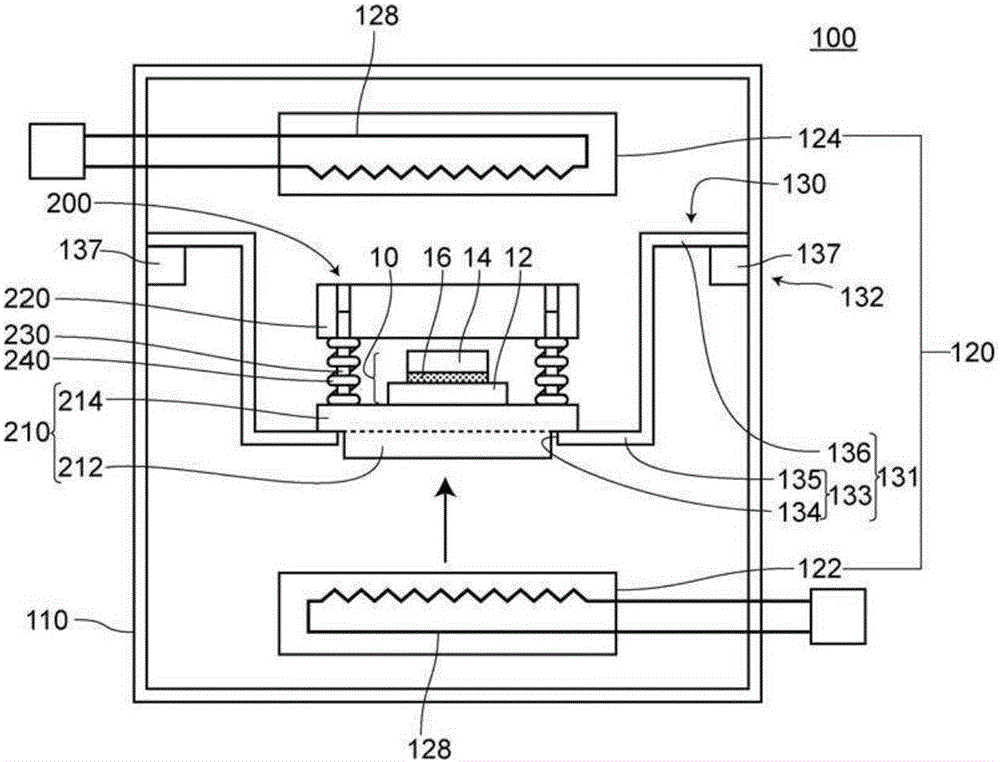

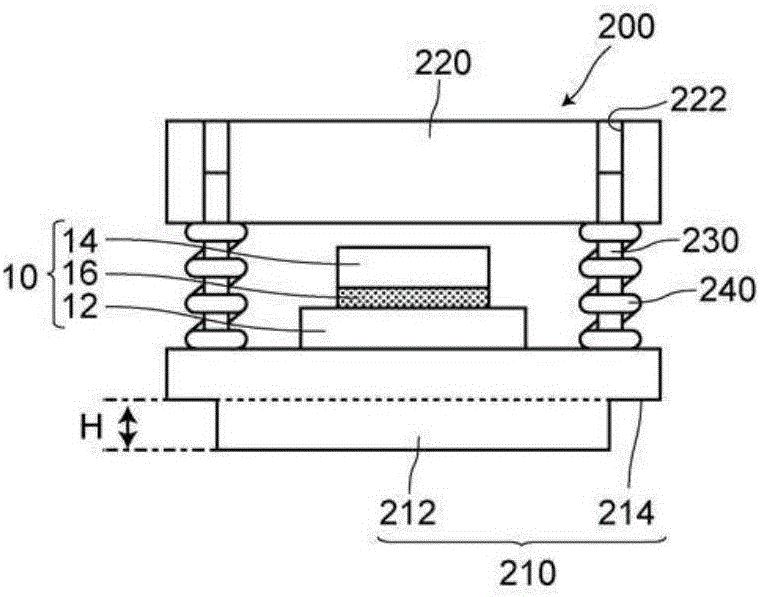

[0042] First, the assembly 10 will be described.

[0043] As shown in FIG. 1, the assembly 10 is an assembly in which electronic components 14 are arranged on a substrate 12 on which a conductor circuit pattern is formed via a metal particle paste 16.

[0044] The "substrate" in this specification refers to a component on which electronic components are mounted.

[0045] The substrate 1 in the first embodiment is, for example, a circuit substrate in which a conductor pattern is formed on a main body made of a non-conductive material. As a constituent material of the substrate 1, a material that can withstand the sintering temperature of the metal particle paste 4 (depending on the type, for example, 300°C) can be used (for example, the body is heat-resistant resin or ceramic, and the wire distribution diagram is Metal).

[0046] In addition, the substrate to which the present invention is applied may be a DCB (Direct Copper Bond) substrate. In addition, the substrate to which the pr...

Embodiment approach 2

[0113] The bonding device (not shown) according to the second embodiment basically has the same structure as the bonding device 100 according to the first embodiment, but it does not move only the first heating part but also the second heating part. It is different from the joining device 100 related to the first embodiment in one point. That is, in the bonding device according to the second embodiment, the pressurizing structure portion moves the second heating portion downward while moving the first heating portion upward.

[0114] In addition to the components of the pressing structure 140 in the first embodiment, the pressurizing structure unit further includes: a second heating unit driving unit that moves the second heating unit and a second heating unit that controls the second heating unit drive. Department of drive control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com