Tank car manhole and production technology thereof

A production process and tank car technology, which is applied in infrastructure engineering, underwater structures, buildings, etc., can solve the problems of complex production process, large amount of materials, waste materials, high stress concentration, etc., and achieve simple process and improvement of stress concentration phenomenon , to avoid the effect of section mutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

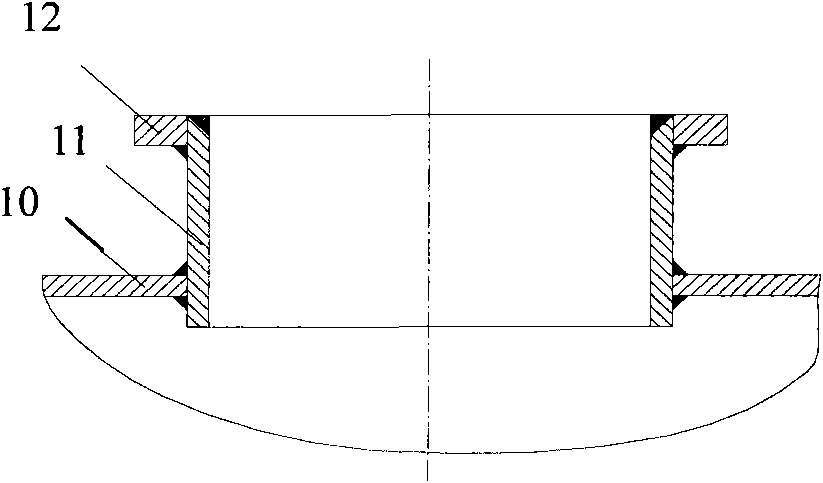

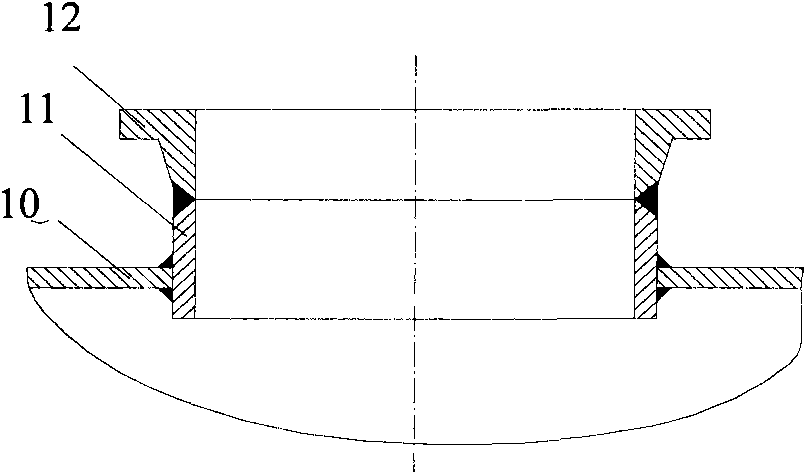

[0039] See Figure 2.1 The tanker manhole structure proposed by the present invention includes a tank body 1, a manhole flange 2, a manhole neck 3. The tank body 1 is a part of the tanker; a small hole is opened on the tank body, and it is reinforced to a special tooling. In the edge process, part of the material needed to form the manhole neck 3 is pulled out, trimmed, beveled, and then welded to the manhole flange 2; the manhole neck 3 is a part of the tank body 1, and the two are integrated.

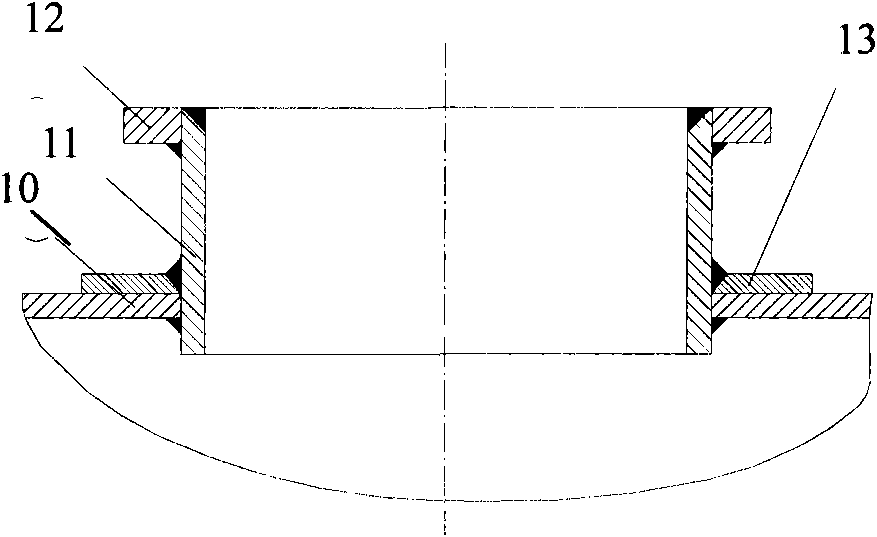

[0040] For another embodiment of the present invention, see Figure 2.2 The tank body 1 is drawn, flanged, trimmed, and beveled according to the above method. The manhole seat edge 4 is used to replace the manhole flange. The manhole seat edge 4 itself has a certain height and can replace part of the manhole neck. The height of the drawing and flanging can be reduced when the body 1 is needed. The tank 1 is trimmed and welded with the manhole seat edge 3 after the groove is processed; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com