Catalyst prepared by loading zinc trifluoromethanesulfonate on macroporous-mesoporous material, and preparation method and use thereof

A technology of zinc trifluoromethanesulfonate and mesoporous materials, which is applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, carboxylate preparation, etc., and can solve the practical application of limited mesoporous materials value, chemical reactivity is not high, and macromolecules are difficult to enter the pores, etc., to achieve good acid conversion rate, reduce side reactions, and improve product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

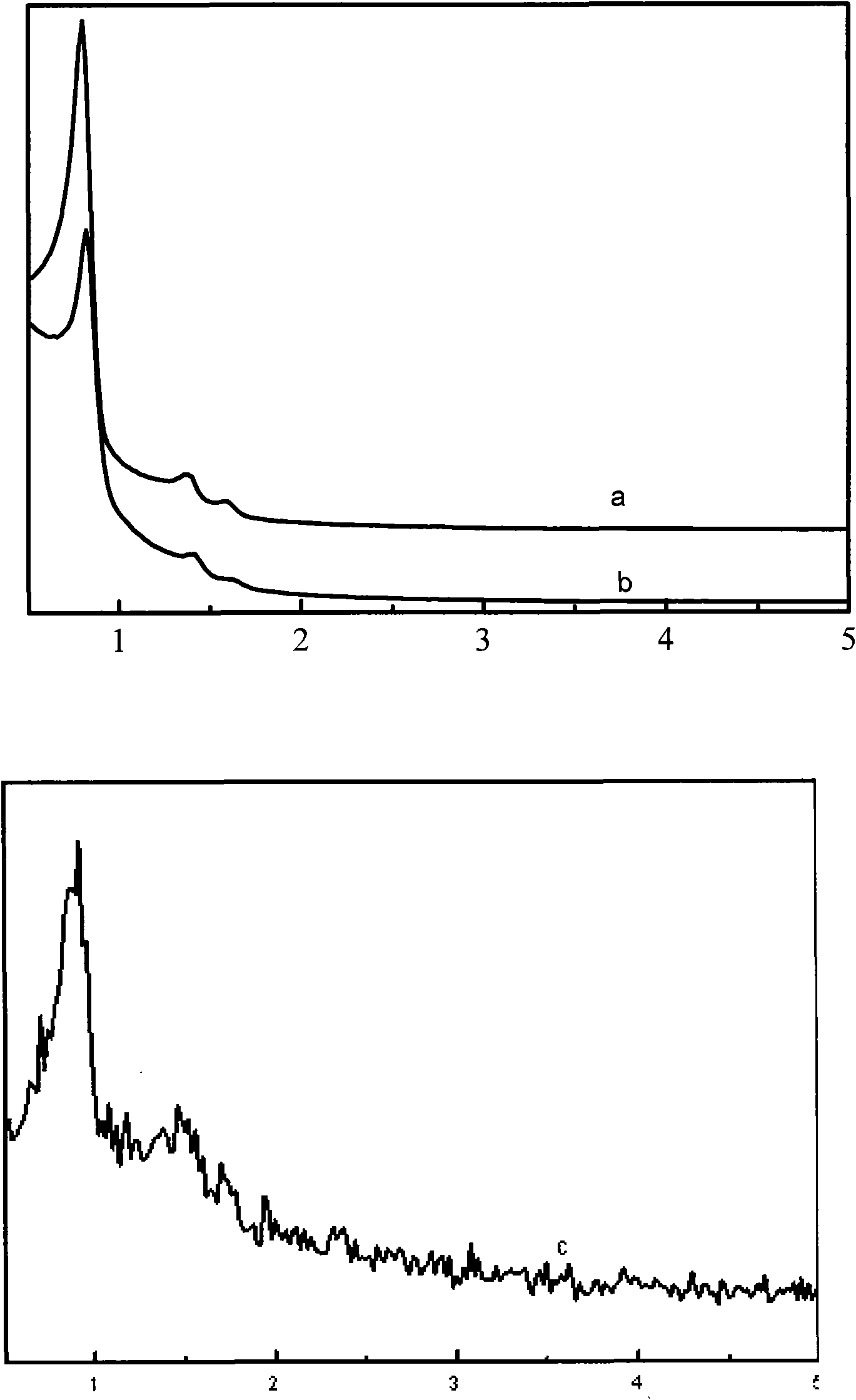

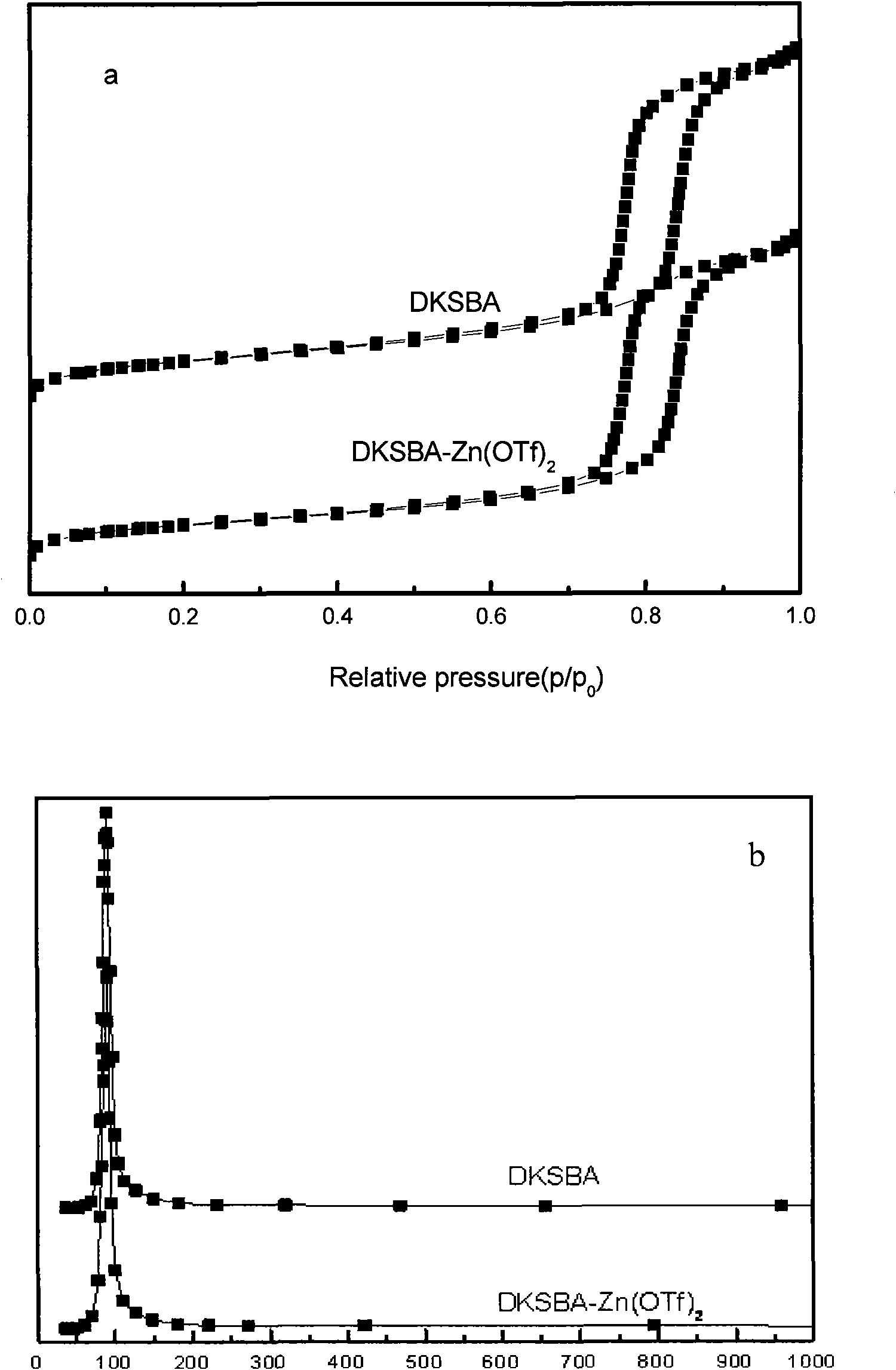

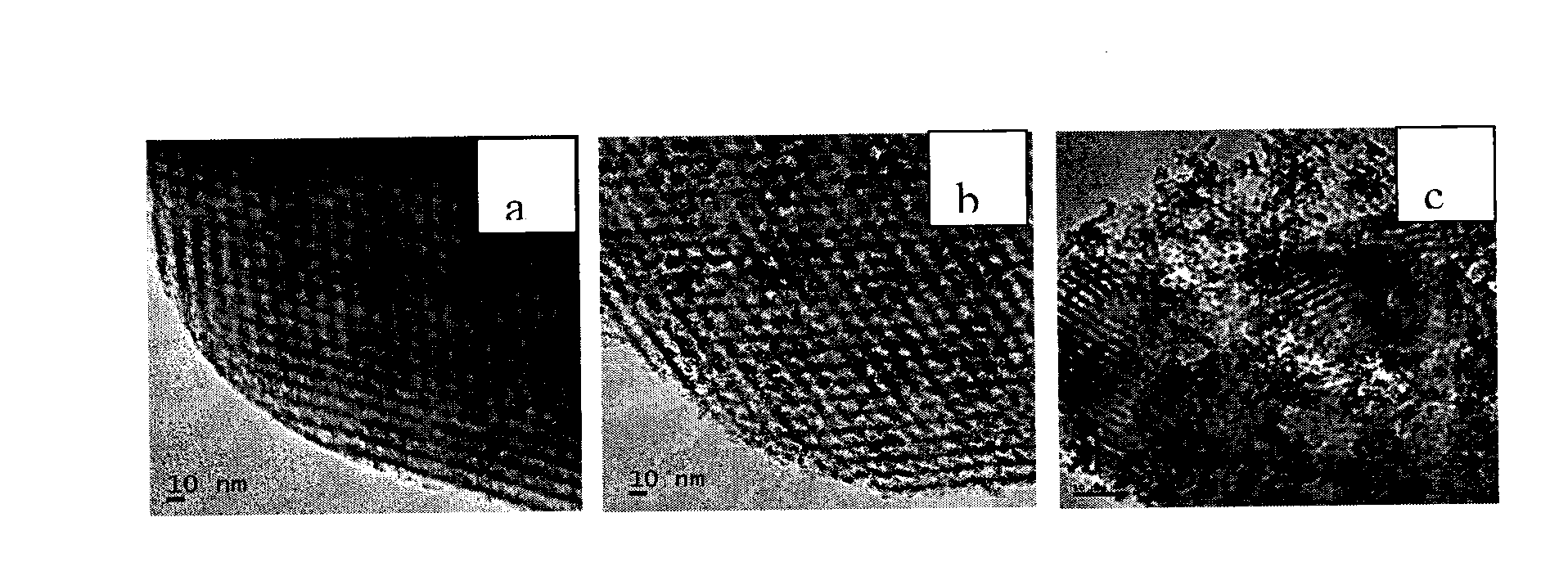

[0030] Example 1 Preparation of macroporous mesoporous material loaded with zinc trifluoromethanesulfonate

[0031] (1) 4.0 grams of P123 (the registration number in the American Chemical Abstracts is the substance of 9003-11-6, its average molecular weight Mn=5800) is added in the solution of 37% 16.4ml hydrochloric acid and 128ml water, stirred at 40 ℃ Until P123 is completely dissolved;

[0032] (2) Add 8.86 grams of ethyl orthosilicate to the above solution, and stir at 40° C. for 24 hours;

[0033] (3) Transfer the obtained solution to a polytetrafluoroethylene-lined reactor, and crystallize at 150° C. for 24 hours;

[0034] (4) Obtain the former powder mesoporous material after filtering, washing and drying;

[0035] (5) Washing the raw powder mesoporous material with ethanol under reflux conditions for 24 hours to remove the template agent to obtain a macroporous mesoporous material;

[0036] (6) Vacuum dry 1g of the above-mentioned macroporous mesoporous material at 1...

Embodiment 2

[0039] Embodiment 2 prepares methyl oleate

[0040] Weigh 1 gram of macroporous mesoporous material catalyst SBA-Zn(OTf) 2 , and then weighed 7.05 grams of oleic acid and 5.6 grams of methanol and put them into a 100ml three-necked flask together with a condenser, stirred for 4 hours under the condition of heating and reflux at 60°C, cooled to room temperature, centrifuged, and used gas chromatography Analysis of the liquid components of the reaction product showed that the content of methyl oleate was 50.5%, and the content of oleic acid was 40.8%. Macroporous Mesoporous Material Catalyst SBA-Zn(OTf) 2 Vacuum-dried at 150°C for 6 hours, cooled to room temperature, and recovered for reuse.

Embodiment 3

[0041] Embodiment 3 prepares methyl oleate with the catalyst that reclaims

[0042] 1 gram of macroporous mesoporous material catalyst SBA-Zn(OTf) that embodiment 2 recycles 2 , and then weighed 7.05 grams of oleic acid and 5.6 grams of methanol and put them into a 100ml three-necked flask together, and then added a condenser, stirred for 4 hours under the condition of heating and reflux at 60°C, cooled to room temperature, centrifuged, and used gas chromatography Analysis of the liquid components of the reaction product showed that the content of methyl oleate was 18.2%, and the content of oleic acid was 81.8%. Macroporous Mesoporous Material Catalyst SBA-Zn(OTf) 2 Vacuum-dried at 150°C for 6 hours, cooled to room temperature, and recovered for reuse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com