Alloy material for positive grid of storage battery and preparation method thereof

An alloy material and battery technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of destroying the lead furnace, corrosion and fracture of the grid, shortening the service life of the lead pump, etc., to improve the castability, cycle life, and combination performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take the preparation of 100kg alloy material as an example to describe in detail.

[0039] 1: Raw material selection and weighing:

[0040] 1. Lead ingot: 1# electrolytic lead

[0041] 2. Copper or copper alloy: pure copper or copper alloy, wherein the copper content in the copper alloy is greater than or equal to 90%, totaling 0.02kg to 0.04kg;

[0042] 3. Calcium block: purity ≥99%, 0.10~0.13kg;

[0043] 4. Tin ingot: grade above 99.9, flat-type front grid: 0.3-0.6kg; tube-type front grid: 1.0-1.3kg;

[0044] Two: Preparation process and key points

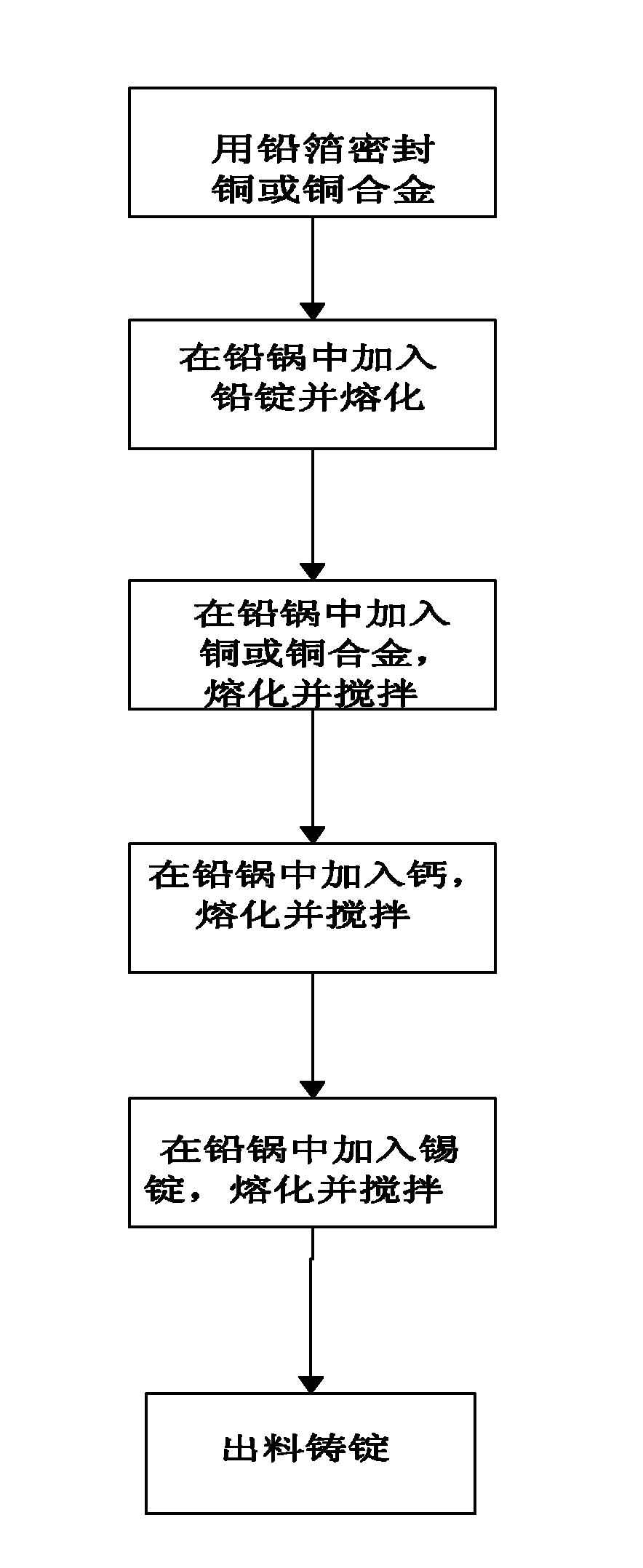

[0045] Such as figure 1 Shown is the flow chart of the method for preparing Pb-Ca-Sn-Cu quaternary alloy material or multi-element alloy II in the present invention.

[0046] 1. Wrap and seal copper or copper alloy with lead foil, or fill it in a hollow lead block for use.

[0047] 2. Weigh 1# electrolytic lead with 80% of the volume of the lead pot, heat to melt the electrolytic lead to form lead liquid, and keep t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com