Micromechanical structure and method for manufacturing micromechanical structure

一种微机械结构、电极结构的技术,应用在制造微观结构装置、微结构技术、微观结构装置等方向,能够解决不能表面结构差分式分析处理等问题,达到提高偏移量或零点稳定性、实现应力去耦合、好信噪比的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

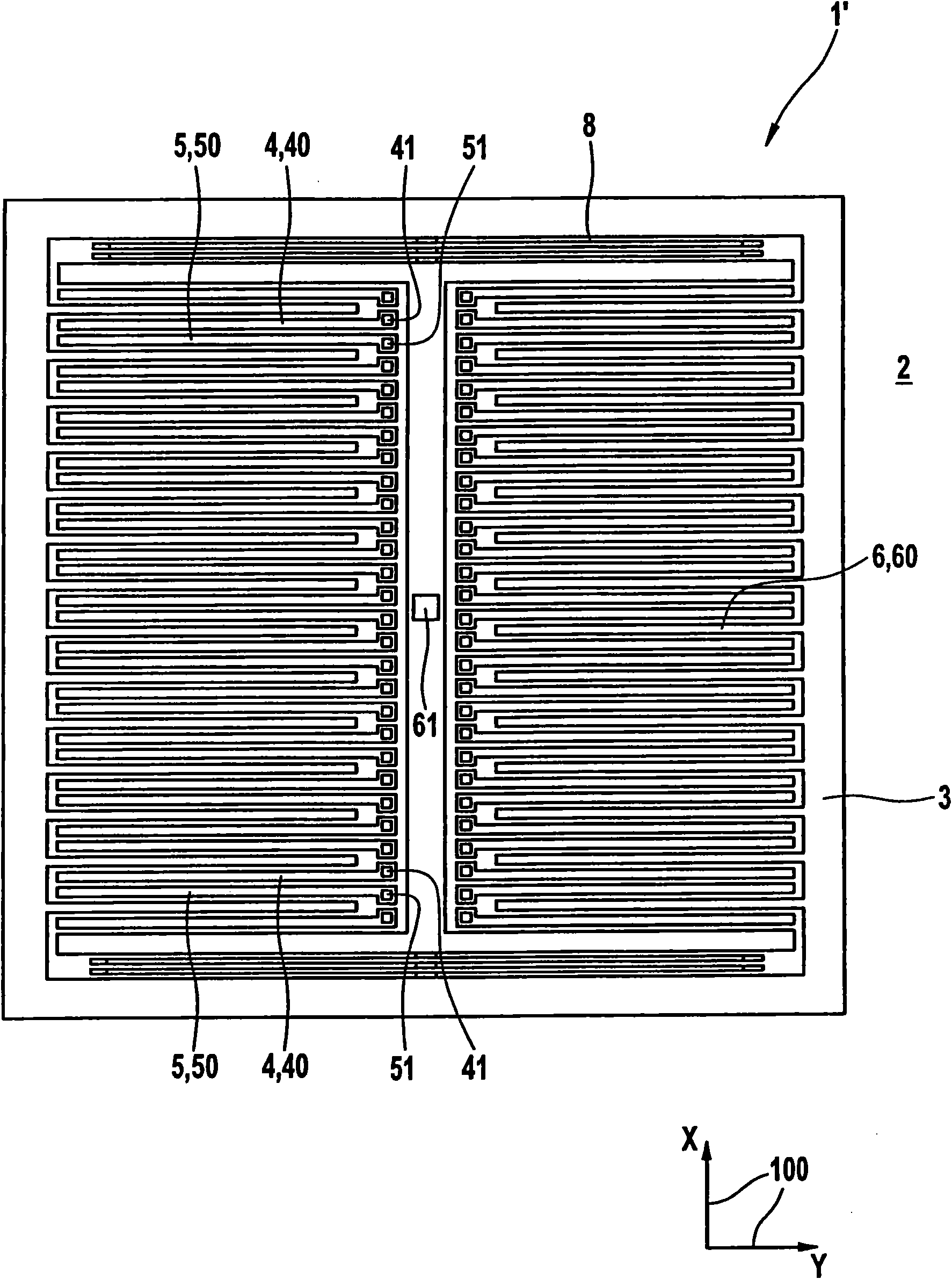

[0021] exist figure 1A schematic top view of a micromechanical structure 1' according to the prior art is shown in . The micromechanical structure 1' comprises a substrate 2 having a main plane of extension 100 and a seismic mass 3 movable relative to the substrate 2. The seismic mass 3 is coupled via the spring element 8 to a third anchoring element 61, which is fixedly connected to the substrate 2 in the central region 7 of the micromechanical structure 1'. Seismic mass 3 also includes a counter-electrode structure 6 with third finger electrodes 60 . The micromechanical structure 1' also comprises a first and a second electrode structure 4,5. The first electrode structure 4 includes first finger electrodes 40 in the form of spanner arms, wherein each of the first finger electrodes 40 is fixed on the substrate 2 via its own first anchoring element 41 . The second electrode structure 5 includes second electrode fingers 50 in the form of spanner arms, wherein the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com