Aluminasol bonded alumina mould case and manufacturing method thereof

A kind of alumina and aluminum sol technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve problems such as waste, casting surface pollution, damage to casting quality, etc., to achieve controllable process parameters and meet thermal shock resistance , the effect of not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

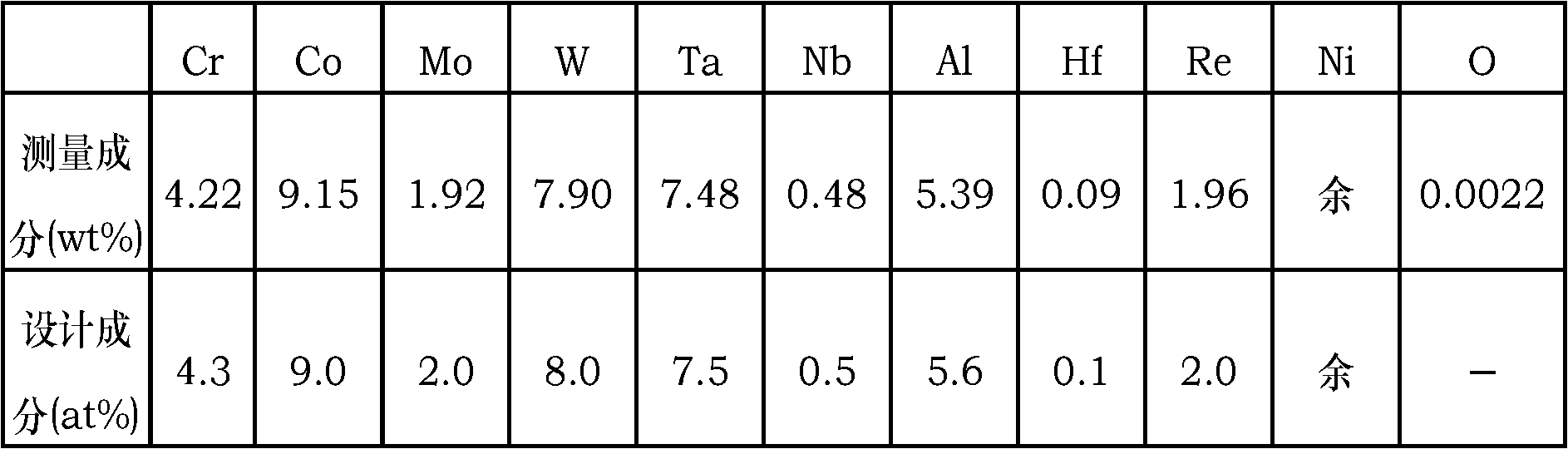

[0065] Alumina sol bonded alumina formwork for directionally solidified DD6 alloy (composition shown in the table below)

[0066] Element

Cr

co

Mo

W

Ta

Nb

Al

f

Re

Ni

Content / wt%

4.3

9.0

2.0

8.0

7.5

0.5

5.6

0.1

2.0

Remain

[0067] The first step: prepare the formwork slurry

[0068] The mold shell slurry is composed of aluminum sol (LA-25 aluminum sol produced by Zibo Jinqi Chemical), alumina powder, Cr 2 o 3 (mineralizer), ammonium polyacrylate (dispersant), n-octanol (defoamer) and JFC (wetting agent), the content of each component is shown in the table below:

[0069] Element

Aluminum sol

Cr 2 o 3

ammonium polyacrylate

n-octanol

JFC

Content / wt%

23

71.2

5

0.6

0.1

0.1

[0070] Step Two: Prepare the Formwork

[0071] (A) immerse the wax pattern of casting shape into t...

Embodiment 2

[0093] Pouring Ni 3 Aluminum sol-bonded alumina formwork for Al-based alloys (composition shown in the table below)

[0094] Element

Ni

Al

Mo

Re

Content / wt%

Remain

7.8

12.5

1.5

[0095] The first step: prepare the formwork slurry

[0096] The mold shell slurry is composed of aluminum sol (LA-20 aluminum sol produced by Zibo Jinqi Chemical), alumina powder, MgO (mineralizer), ammonium polyacrylate (dispersant), n-octanol (defoamer) and JFC (wetting agent); the content of each component is shown in the table below:

[0097] Element

Aluminum sol

Alumina powder

MgO

ammonium polyacrylate

n-octanol

JFC

Content / wt%

28

68.3

3

0.5

0.1

0.1

[0098] Step Two: Prepare the Formwork

[0099] (A) immerse the wax pattern of casting shape into the slurry prepared in the first step for 2 seconds and then take it out, sprinkle with 80 mesh alumina sand to for...

Embodiment 3

[0118] Aluminum sol bonded alumina formwork for directionally solidified TMS75 alloy (composition shown in the table below)

[0119] Element

Cr

co

Mo

W

Ta

Al

f

Re

Ni

Content / wt%

3.0

12.0

2.0

6.0

6.0

6.0

0.1

5.0

Remain

[0120] The first step: prepare the formwork slurry

[0121] The mold shell slurry is composed of aluminum sol (LA-25 aluminum sol produced by Zibo Jinqi Chemical), alumina powder, TiO (mineralizer), ammonium polyacrylate (dispersant), n-octanol (defoamer) and JFC (wetting agent); the content of each component is shown in the table below:

[0122] Element

Aluminum sol

Alumina powder

TiO

ammonium polyacrylate

n-octanol

JFC

Content / wt%

24

72

3

0.8

0.1

0.1

[0123] Step Two: Prepare the Formwork

[0124] (A) immerse the wax pattern of the casting shape into the slurry prepared in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com