Catalyst for preparing low-carbon mixed alcohol by using synthesis gas and preparation method thereof

A low-carbon mixed alcohol and catalyst technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of complex product components and unfavorable separation, and achieve the improvement of specific surface area, prevention of sintering, and reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

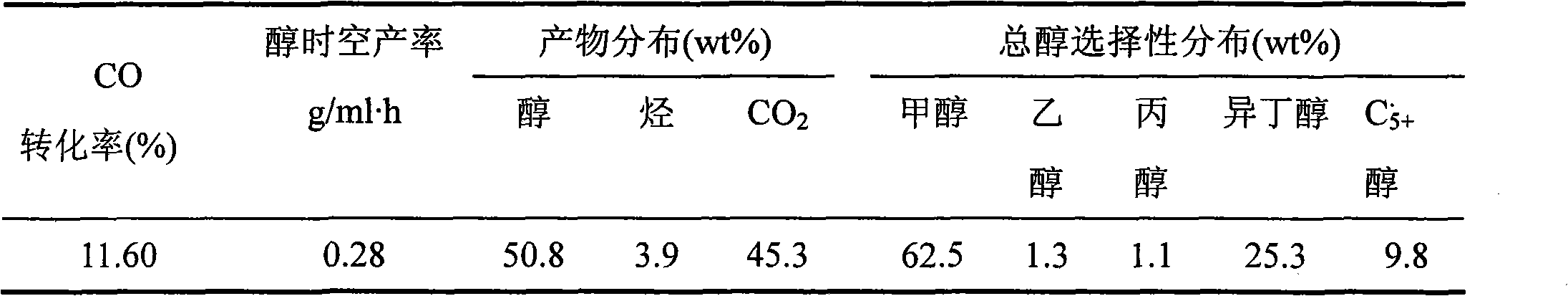

Embodiment 1

[0029] Press ZrO 2 : 69.7wt%, MnO 2 : 15.3wt%, K 2 O: 0.5wt%, Pd: 1wt%, CuO: 4.6wt%, C: 8.9wt%, the nitrates of Zr, Mn, and Cu elements are dissolved in deionized water, and co-precipitated with KOH solution at room temperature, Fully stir during the precipitation process and keep the pH = 13, wash the precipitate with deionized water until neutral, add starch and deionized water to the precipitate and stir evenly, heat and stir to make it into a paste, and dry at 90°C 20 hours, calcined at 500°C for 6 hours in a nitrogen atmosphere, crushed into 20-40 meshes, impregnated with K in an equal volume, dried at 90°C for 20 hours, calcined in a nitrogen atmosphere at 500°C for 6 hours, and then impregnated with an equal volume of Pd ( Pd(NO 3 ) 2 as a precursor), dried at 90°C for 20 hours, and calcined at 330°C for 6 hours in a nitrogen atmosphere to obtain the desired catalyst. CO+H 2 The reaction was carried out in a stainless steel tube reactor with an inner diameter of 1...

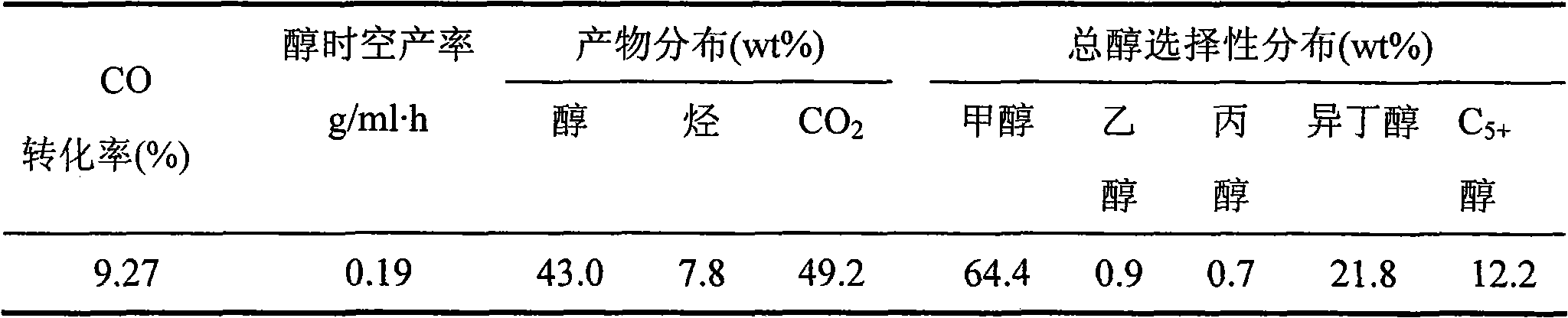

Embodiment 2

[0033] The catalyst composition is ZrO 2 : 73wt%, MnO 2 : 16wt%, K 2 O: 0.5wt%, Pd: 1wt%, CuO: 4.8wt%, C: 4.7wt%, the use conditions are P=6.0MPa, T=340℃, GHSV=7200h -1 , H 2 / CO=1, all the other conditions are with embodiment 1, and the obtained results are as shown in table 2:

[0034] Table 2 Analysis results of gas chromatography

[0035]

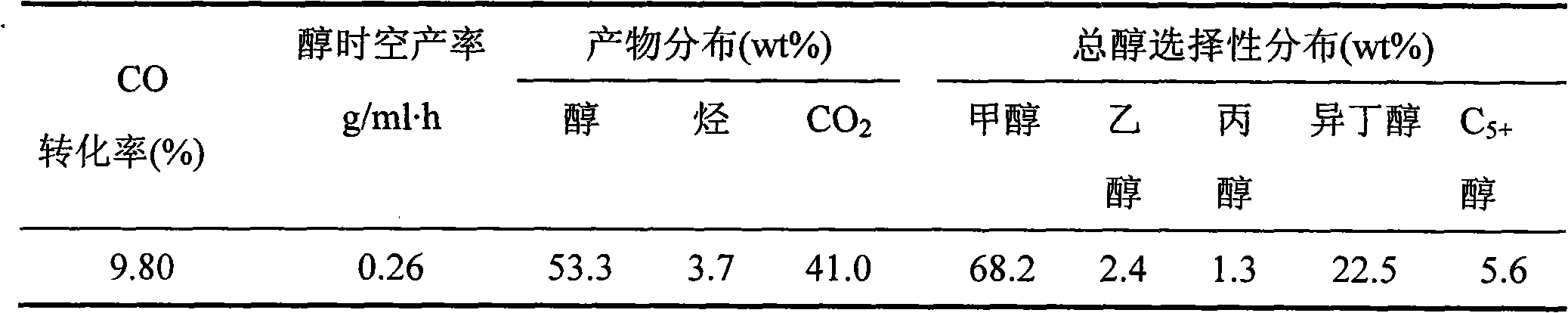

Embodiment 3

[0037] The catalyst composition is ZrO 2 : 63.9wt%, MnO2 : 14.0wt%, K 2 O: 0.5wt%, Pd: 1wt%, CuO: 4.2wt%, C: 16.4wt%, the use conditions are P=6.0MPa, T=340℃, GHSV=7200h -1 , H 2 / CO=1, all the other conditions are with embodiment 1, and the obtained results are as shown in table 3:

[0038] Table 3 Analysis results of gas chromatography

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com