Method for controlling drive circuit of cold-cathode fluorescence lamp and control circuit

A technology of a cold cathode fluorescent lamp and a control method, which is applied in the directions of light sources, electric light sources, electrical components, etc., can solve the problems of increasing the complexity of circuit design, increasing production costs, and complex control circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The CCFL driving circuit control method and control circuit of the embodiments of the present invention will be described in detail below. In the following description, some specific details, such as specific circuit structures in the embodiments and specific parameters of these circuit elements, are used to provide a better understanding of the embodiments of the present invention. It will be understood by those skilled in the art that the present invention may be practiced without many of the details or other combinations of methods, elements, materials, etc.

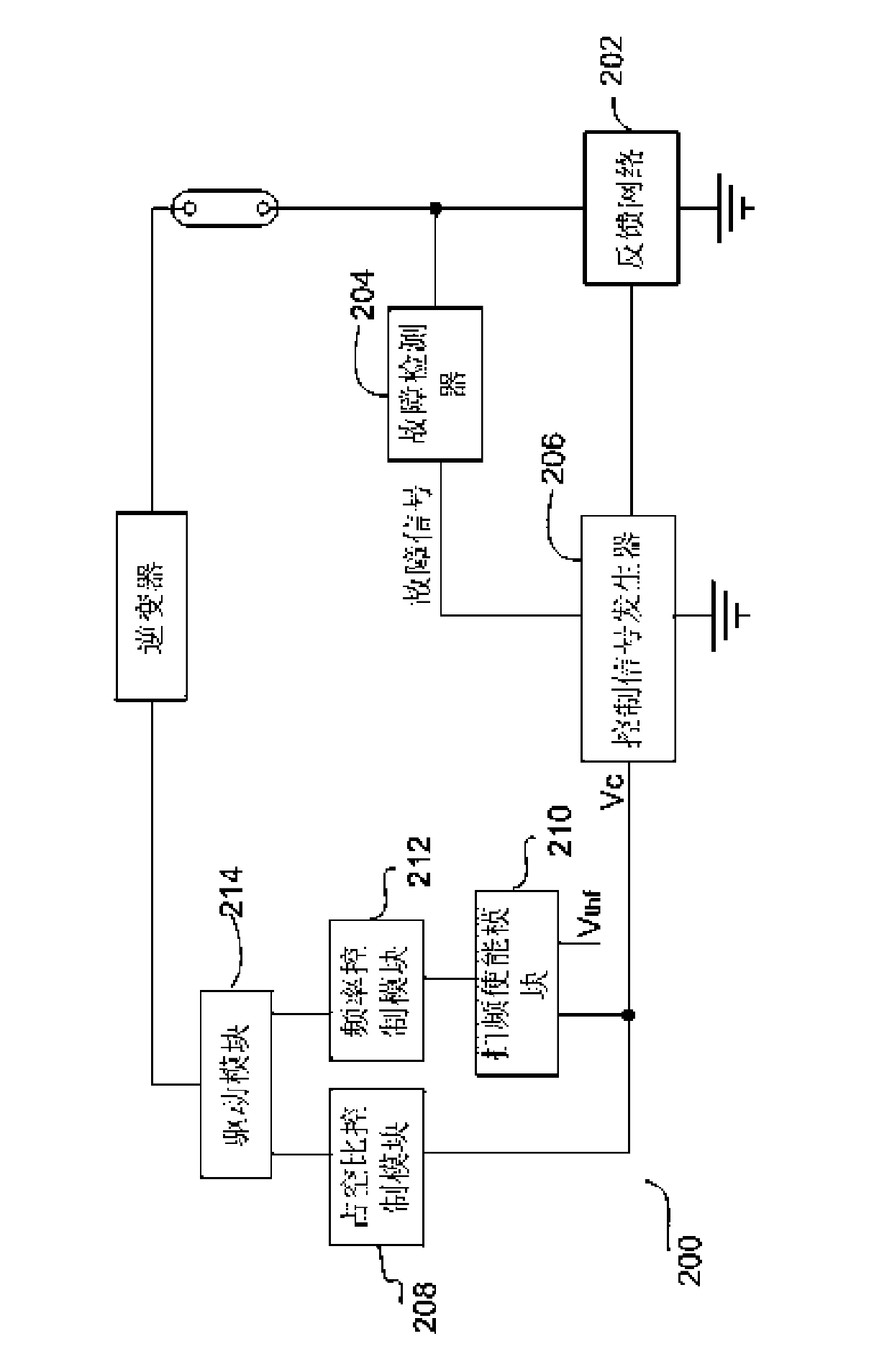

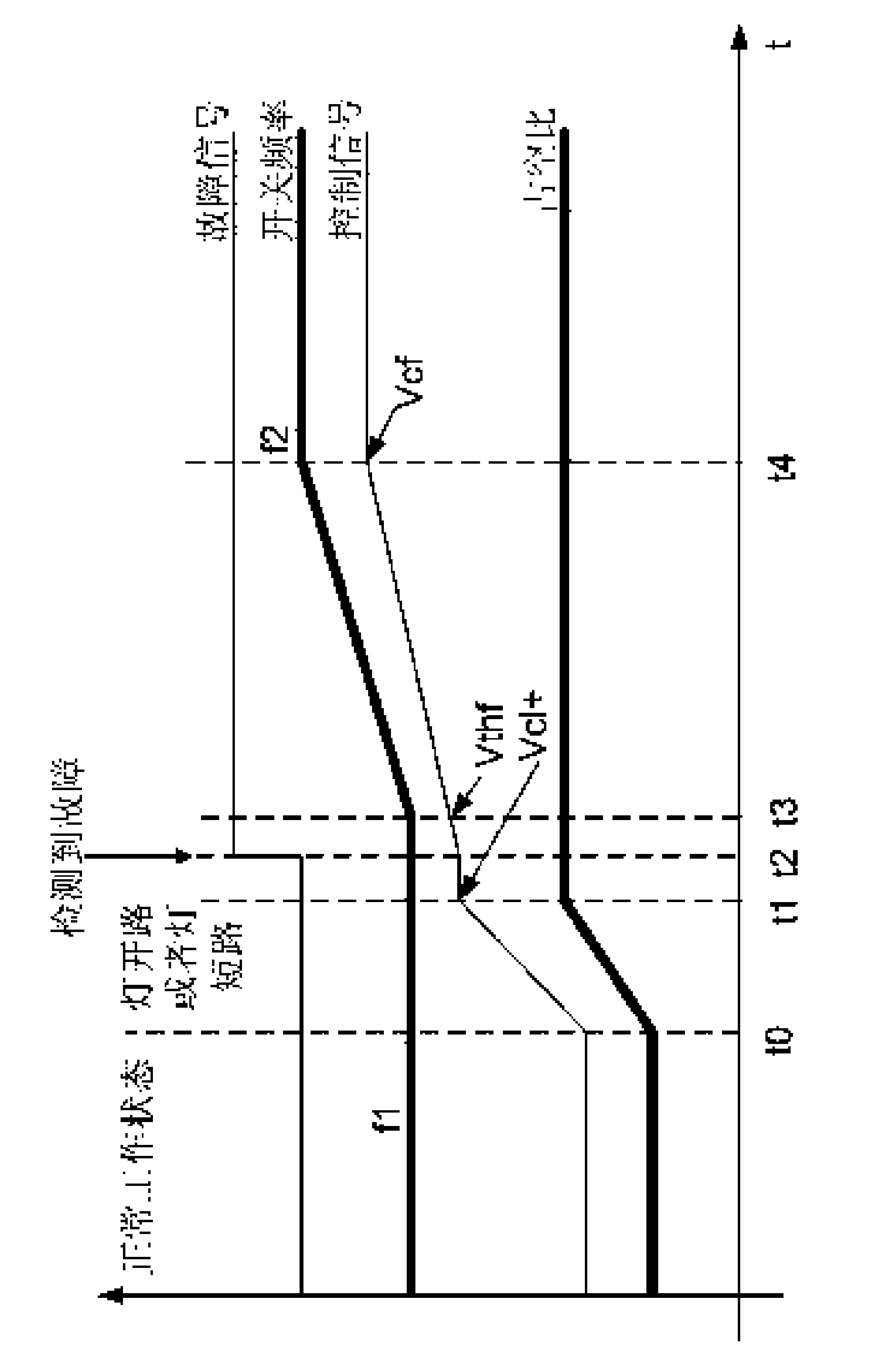

[0064] figure 2 It is a schematic diagram of the CCFL drive circuit control circuit according to one embodiment of the present invention. The control circuit 200 is mainly composed of a feedback network 202 , a fault detector 204 , a control signal generator 206 , a duty cycle control module 208 , a frequency sweep enabling module 210 , a frequency control module 212 and a driving module 214 . The input term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com