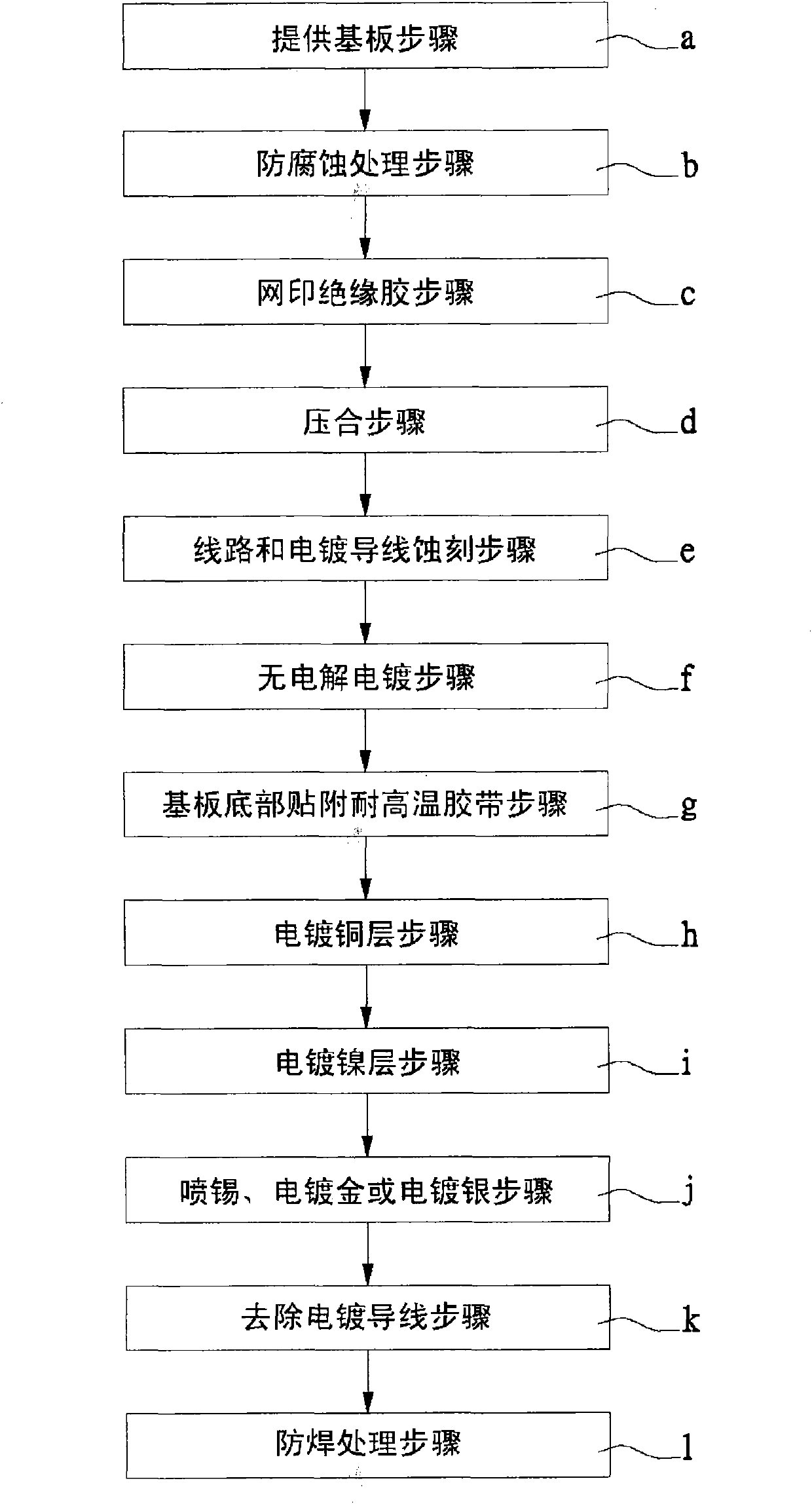

Light-emitting diode radiating substrate and preparation method thereof

A technology for light-emitting diodes and heat-dissipating substrates, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

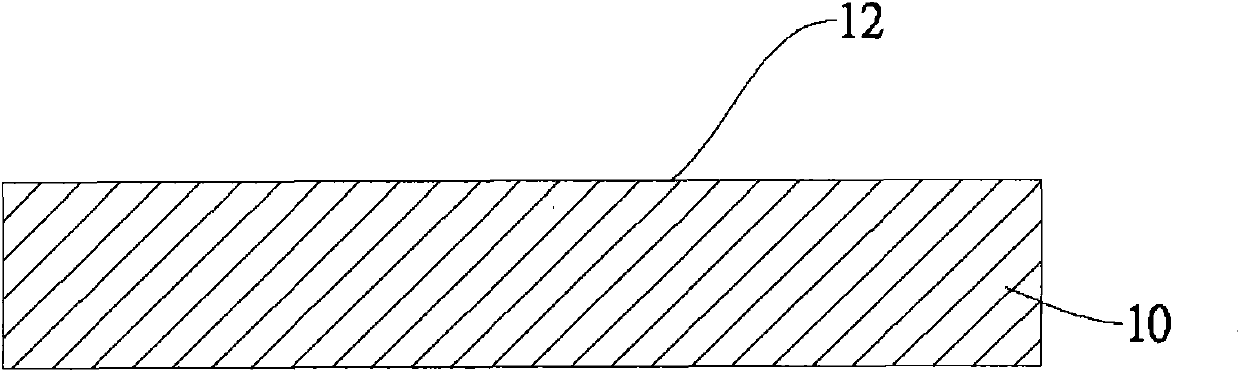

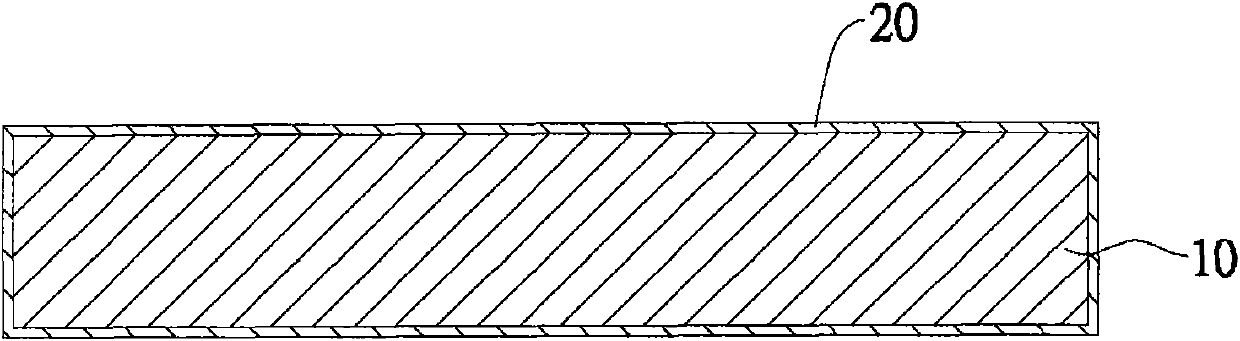

Embodiment Construction

[0040] The "electroless plating" described here is also called "electroless plating", so the terms "electroless nickel plating" and "electroless nickel" can be used interchangeably. It is a method of forming a uniform coating on the workpiece by using a redox reaction without electricity. The electroless plating includes displacement plating (such as ion exchange or charge exchange deposition), contact plating, and essentially electroless plating. This is a well-known technology in the art, but it has not been used to improve the welding characteristics of aluminum substrates.

[0041] The "pretreatment before electroplating" described here generally refers to the treatment carried out before electroplating, but in the present invention is the treatment carried out before electroless plating, and the treatment method is the same, including pickling and Remove the film, oxide layer or rust layer on the surface of the workpiece to increase the adhesion of the coating, and remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com