Gas-sensitive absorption device based on hollow optical fibre

A hollow-core optical fiber and absorption device technology, which is applied in the field of gas sensing detection, can solve the problems of mechanical processing accuracy requirements, light source parallelism requirements, high price, high mechanical accuracy requirements, short optical path, etc., so as to improve the optical transmission efficiency and The effect of gas contact efficiency, low mechanical precision requirements, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: An example of the composition of a hollow-core optical fiber gas-sensitive absorption device

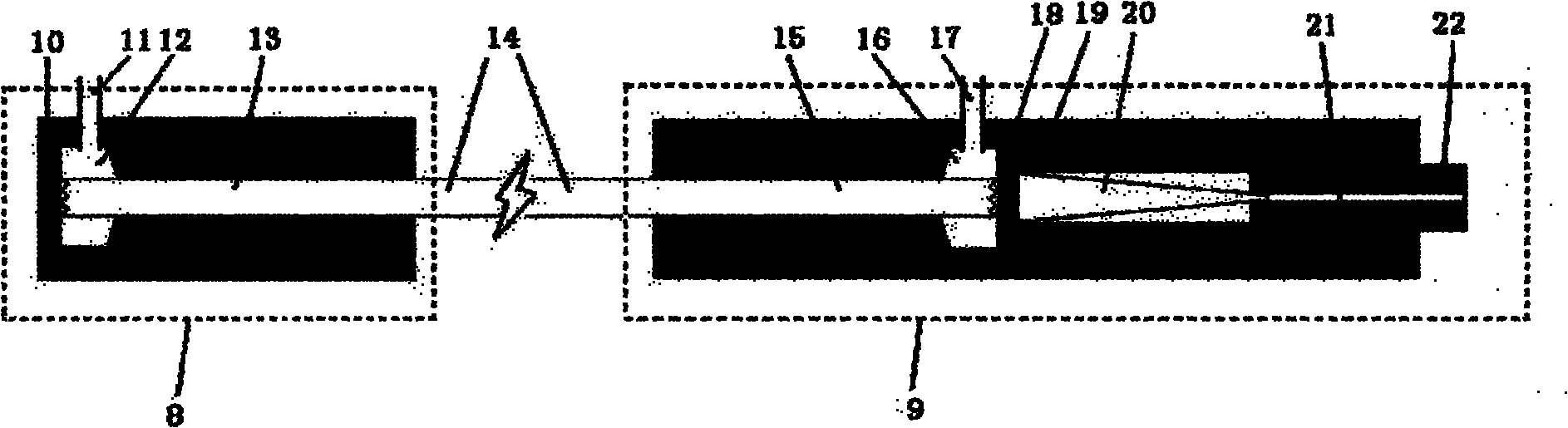

[0035] The air-sensitive absorption device (4) based on the hollow-core optical fiber of the present invention has the characteristics of simple structure and low precision requirement. In this embodiment, the end caps 8 and 9 are processed by a numerically controlled lathe, and the core component of the device, the hollow-core optical fiber, is a self-made hollow-core optical fiber.

[0036] The front end head (8) is processed by a numerically controlled lathe, and the base material is made of polyurethane plastic (PU), or chemically stable plastics or alloys such as polytetrafluoroethylene (PTFE) and polyethylene (PE). A polyurethane plastic (PU) rod with a diameter of 16mm is selected, and the length is cut to 20mm. Holes are drilled along the central axis to form a first hollow-core optical fiber hole (13), a first micro air chamber (12) and a clamping hole ...

Embodiment 2

[0040] Embodiment 2: the device of the present invention replaces the example of air chamber absorption device

[0041] The use of the hollow-core optical fiber gas-sensing absorption device (4) to replace the open air chamber can improve the light transmission efficiency, increase the detection optical path, and reduce the requirements of the spectral detection method on the light source. We used a comparative experimental device to test the light transmission effect of the hollow-core optical fiber gas-sensing absorption device (4) replacing the open absorption gas chamber.

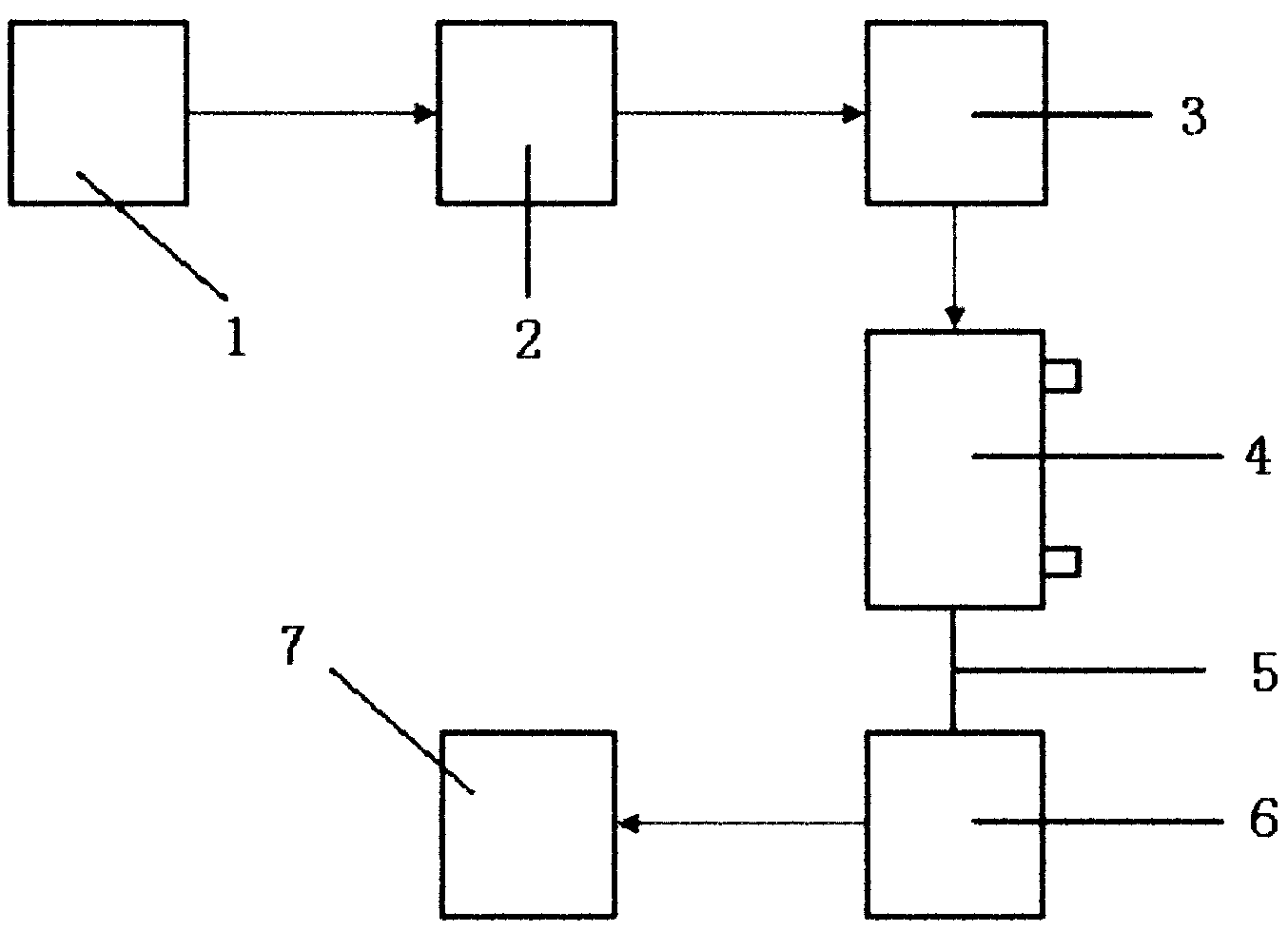

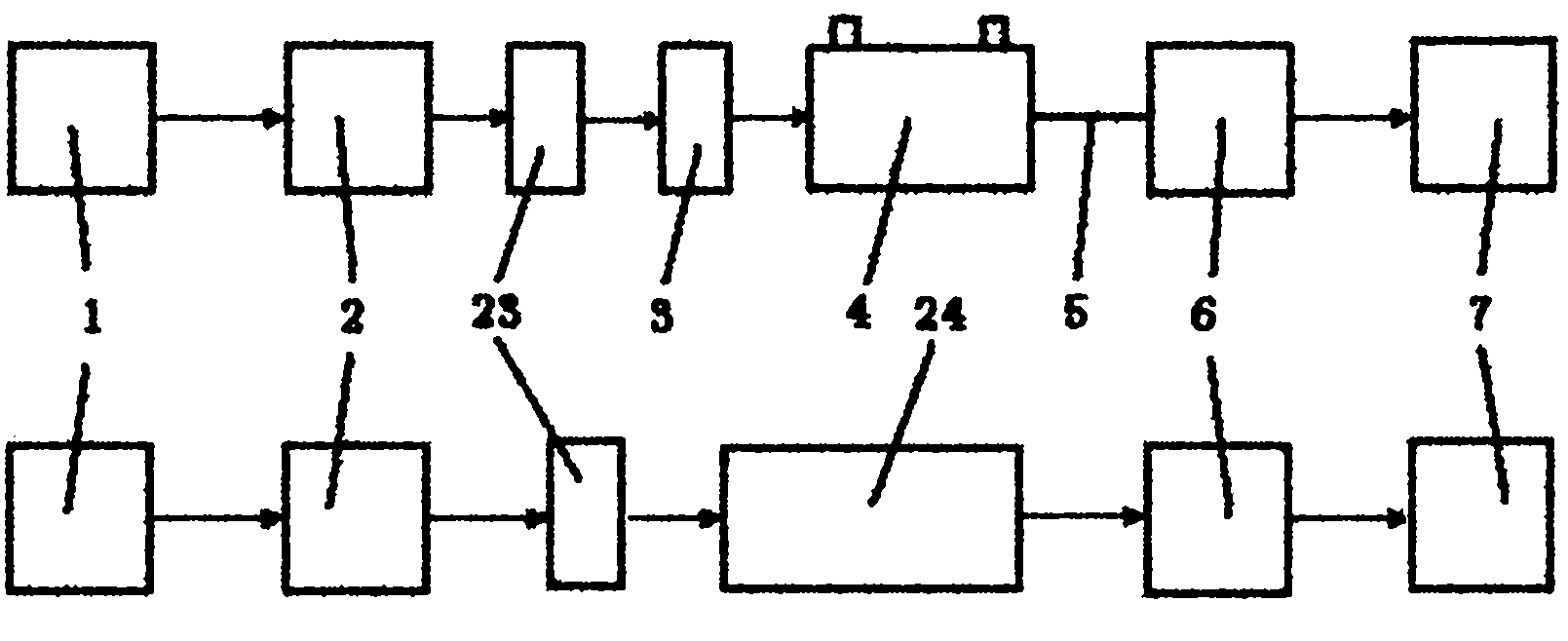

[0042] Experimental device such as image 3 As shown, the optical path structure includes a light source (1), a monochromator (2), an optical chopper (23), a coupler (3), a hollow-core fiber gas-sensitive absorption device (4), a pigtail (5), a photosensitive Component (6), amplifier circuit (7). The contrast optical path includes a light source (1), a monochromator (2), an optical chopper (23), a cou...

Embodiment 3

[0057] Example 3: Application of hollow-core optical fiber gas-sensitive absorption device

[0058] The hollow-core optical fiber gas-sensing absorption device (4) has the characteristics of simple processing, high light source utilization rate and wide transmission range, and the device can directly replace the gas-sensing absorption device in existing instruments to form a new instrument. Various types of gas detection instruments can be constructed conveniently by using the hollow-core optical fiber gas-sensing absorption device (4), light source (1), detector (6), data processing (7) and other systems.

[0059] like figure 1 , 2 As shown, the hollow-core optical fiber gas-sensing absorption device (4), bromine tungsten lamp light source (1), adjustable monochromator (2), coupling lens (3), InGaAs detector (6), host computer system (7) Form a near-infrared detection system. The light emitted by the bromine tungsten light source (1) is incident on the adjustable monochrom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com