Method for preparing superior fuel oil from inferior crude oil

A technology of low-quality feedstock oil and feedstock oil, which is applied in the field of catalytic conversion combination of hydrocarbon oil, can solve the problems of low propylene yield, underutilization of gasoline latent content, increase of dry gas yield, etc., and achieve reduction of oil slurry yield, It is beneficial to the operation of the catalytic cracking unit and the effect of improving the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

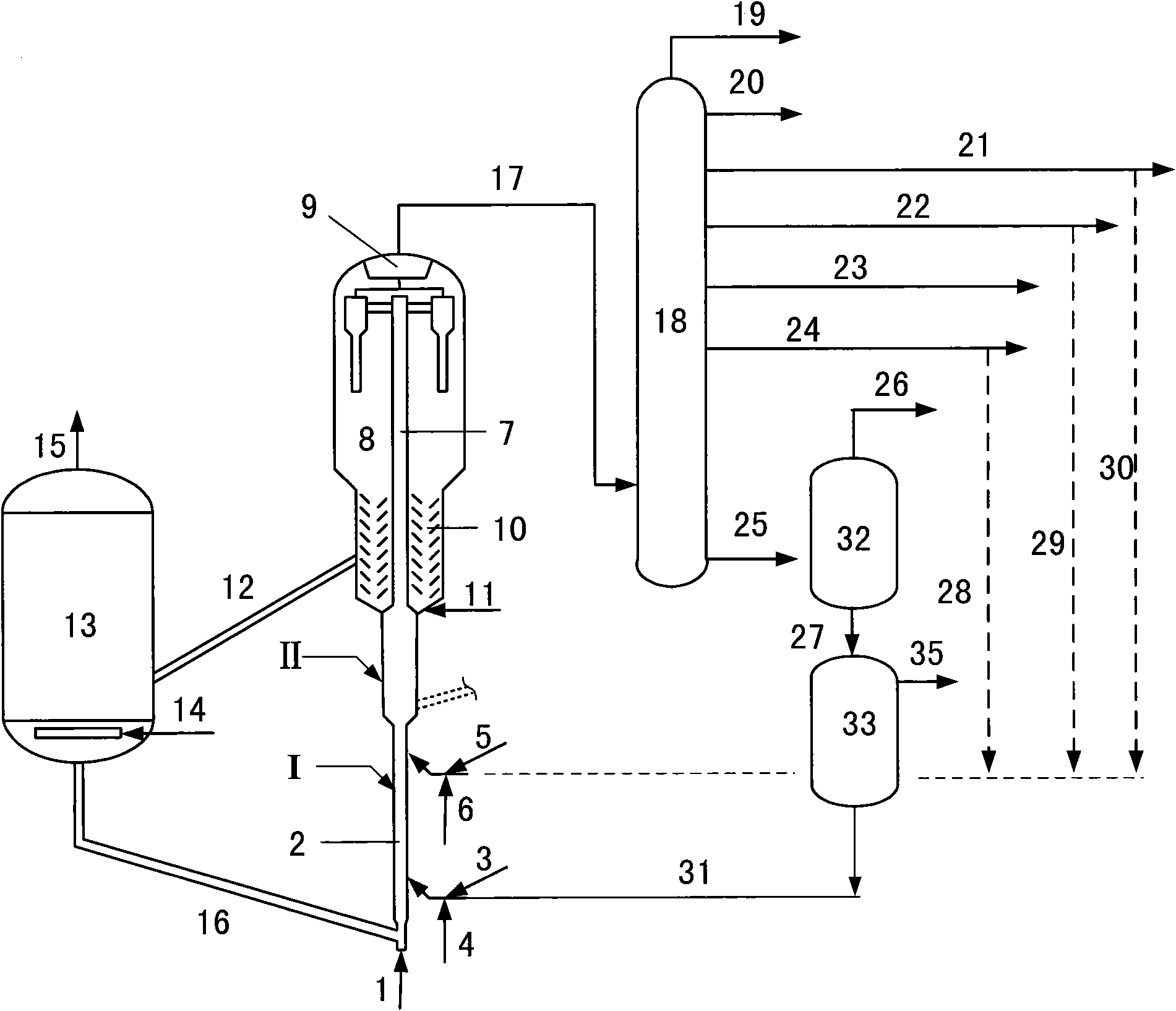

[0065] This example follows figure 1 The process of vacuum residue oil A is used as the raw material for catalytic cracking, and the test is carried out on the medium-sized device of the riser reactor. The inferior raw material enters the lower part of the reaction zone I, contacts with the catalyst GZ-1 and reacts. In the lower part of zone I, low-quality raw materials are subjected to cracking reaction at a reaction temperature of 600°C, a reaction time of 0.4 seconds, a weight ratio of catalyst to raw material of 6, and a weight ratio of water vapor to raw material of 0.05; After mixing propane, C4 hydrocarbons and diesel oil, the cracking reaction is carried out at a reaction temperature of 500°C, a reaction time of 5 seconds, and a weight ratio of water vapor to raw material of 0.05. The distillation range is cut to obtain dry gas, liquefied gas (including propylene, propane and C4 hydrocarbons, the same below), gasoline, diesel oil and catalytic wax oil with a cut point ...

Embodiment 2

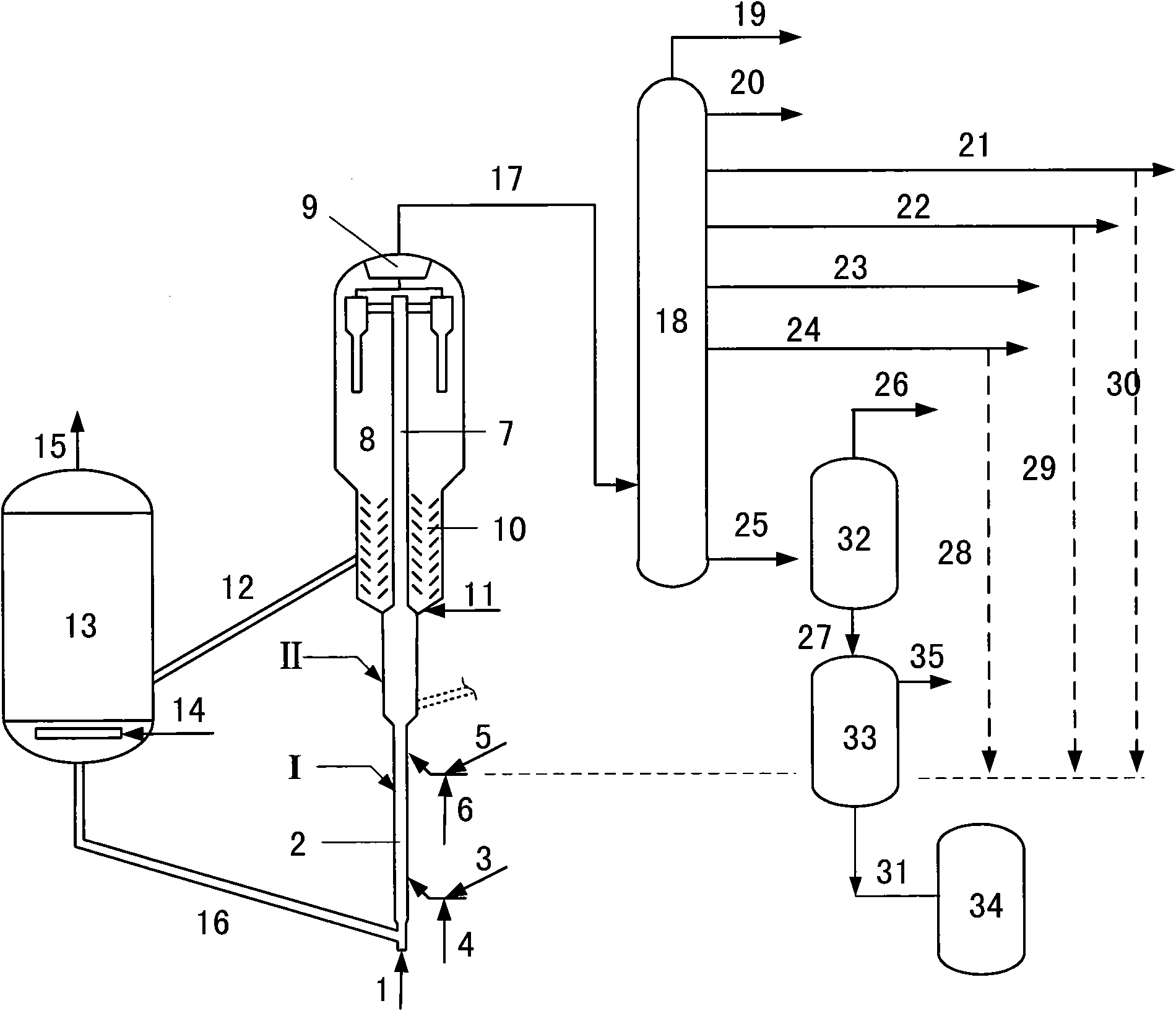

[0071] This example follows figure 2 Inferior hydrogenation residue raw material C was used as the raw material for catalytic cracking, and the test was carried out on the medium-sized device of the riser reactor. The inferior raw material entered the lower part of the reaction zone I, contacted with the catalyst GZ-1 and reacted. In the lower part of zone I, low-quality raw materials are subjected to cracking reaction at a reaction temperature of 600°C, a reaction time of 0.4 seconds, a weight ratio of catalyst to raw material of 6, and a weight ratio of water vapor to raw material of 0.05; After cooling the regenerated catalyst of the excitation medium, the cracking reaction is carried out at a reaction temperature of 500°C, a reaction time of 5 seconds, and a weight ratio of water vapor to raw material of 0.05. The distillation range is cut to obtain dry gas, liquefied gas including propylene, gasoline, diesel oil and catalytic wax oil with a cut point greater than 330 ° C...

Embodiment 3

[0077] This example is based on figure 2 The high-acid crude oil raw material E is used as the raw material for catalytic cracking, and the test is carried out on the medium-sized device of the riser reactor. The inferior raw material enters the lower part of the reaction zone I, contacts and reacts with the catalyst GZ-1, and in the reaction zone I In the lower part, low-quality raw materials are subjected to cracking reaction at a reaction temperature of 600°C, a reaction time of 0.4 seconds, a weight ratio of catalyst to raw material of 6, and a weight ratio of water vapor to raw material of 0.05; , The reaction time is 5 seconds, and the cracking reaction is carried out under the condition that the weight ratio of water vapor to raw material is 0.05. The oil gas and the catalyst with carbon are separated in the settler, and the product is cut according to the distillation range in the separation system, so as to obtain dry gas, including propylene. Liquefied petroleum gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com