Seal welding method of titanium pipe and titanium tube plate of all-titanium condenser

A condenser and sealing welding technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low connection strength, poor air tightness, leaking pipe and tube sheet joints of expansion tubes, etc., to avoid welding The effects of current fluctuations, shortening the construction period, and enhancing the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

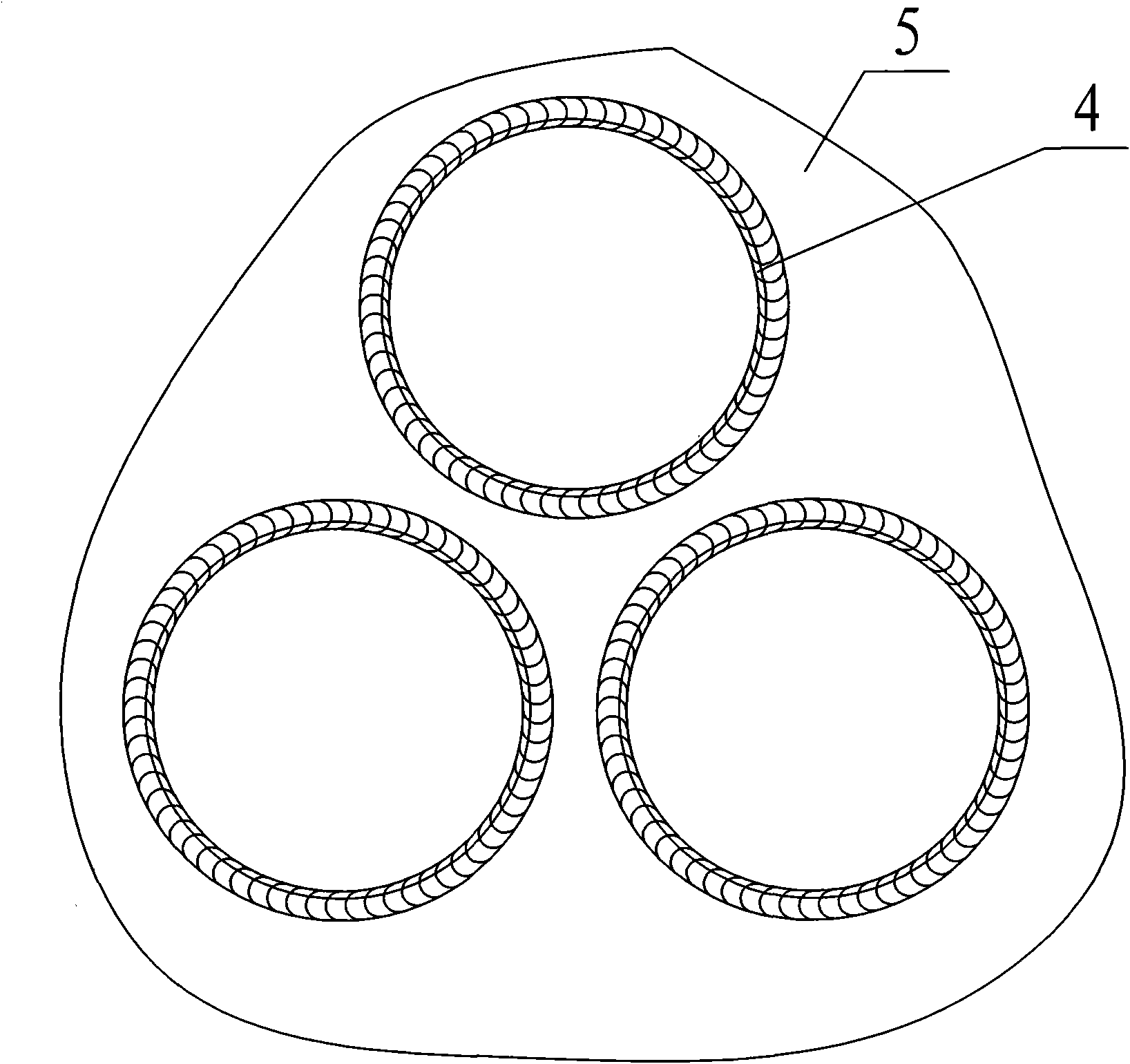

[0029] A sealing welding method between titanium tube and titanium tube plate of an all-titanium condenser. The parameters are selected according to the requirements of the forming size. First, the width of the weld bead is required not to exceed half of the width of the hole bridge, that is, <3mm. Second, the weld bead reinforcement and the tube The size of the inner protrusion is even; when welding titanium, use argon gas to protect the front side of the weld, the reverse side of the weld and the welding area above 200 °C. The shape and penetration form of welding beads with different shielding gases are different. Firstly, the shape and penetration form of argon arc welding bead is adopted; secondly, the shape and penetration form of argon-helium mixed gas welding bead is used; the third is the shape and penetration form of helium welding bead. Melting form11.

Embodiment 2

[0031] The sealing welding method between titanium tube and titanium tube plate of the all-titanium condenser described in embodiment 1, the frontal protection of the weld seam: a single gas cylinder is used for the gas in the protective cover, which is not affected by the start and stop of welding according to a given The flow rate is continuous air supply; use a larger gas flow rate, and the gas flow rate in the protective cover is 4-6 liters per minute.

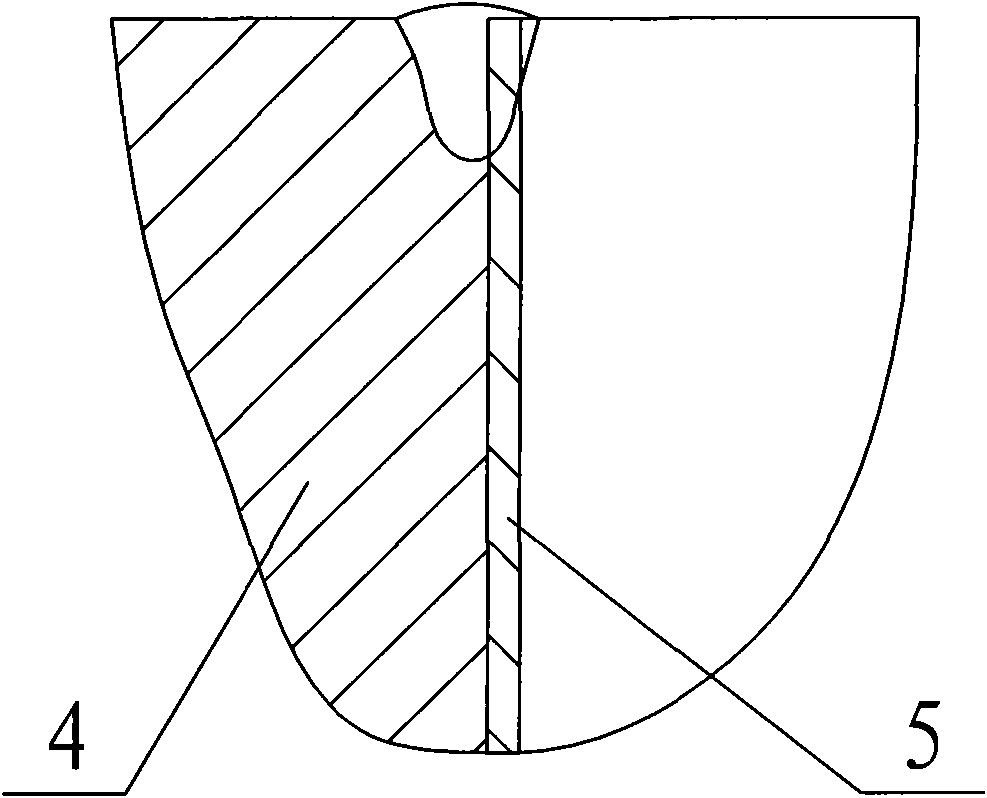

[0032] In the method of sealing welding between titanium tubes and titanium tube sheets of the all-titanium condenser, the protection of the back of the weld seam: first, the process of first expanding the tube and then welding is adopted, which can cut off the intrusion of air during welding and protect the back of the weld seam.

Embodiment 3

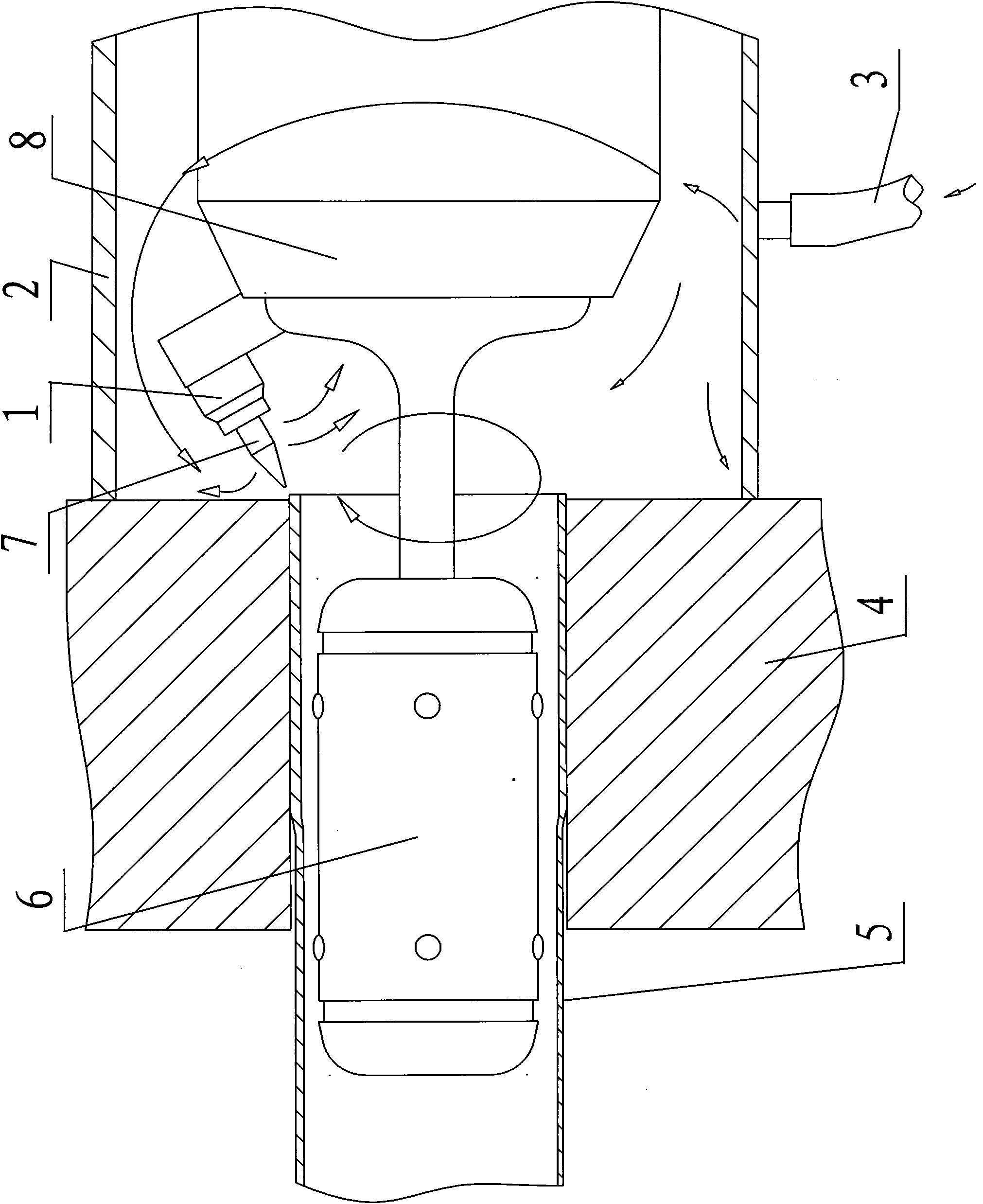

[0034] An all-titanium condenser titanium tube and titanium tube plate seal welding device, which consists of a protective cover 2 with an argon gas inlet 3, the protective cover 2 is connected to a titanium tube plate 4, and the titanium tube The plate 4 is connected to the titanium tube 5 , a spray gun 8 protrudes into the protective cover 2 , the spray gun 7 is connected to the hollow rod 6 , the spray gun 8 has a nozzle 1 , and the nozzle 1 is connected to the electrode 7 .

[0035] Example 3:

[0036] The titanium tube and titanium tube plate sealing welding method of the all-titanium condenser described in embodiment 1 or 2, the 1# machine of Shajiao Power Plant is a 200,000-kilowatt three-exhaust steam condenser unit, and the cooling pipe and the tube plate are all made of industrial pure Titanium, called all-titanium condenser. Its titanium is supplied by Kobe Steel, Japan.

[0037] The titanium tube plate uses the grade 3 titanium plate in the Japanese Industrial St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com