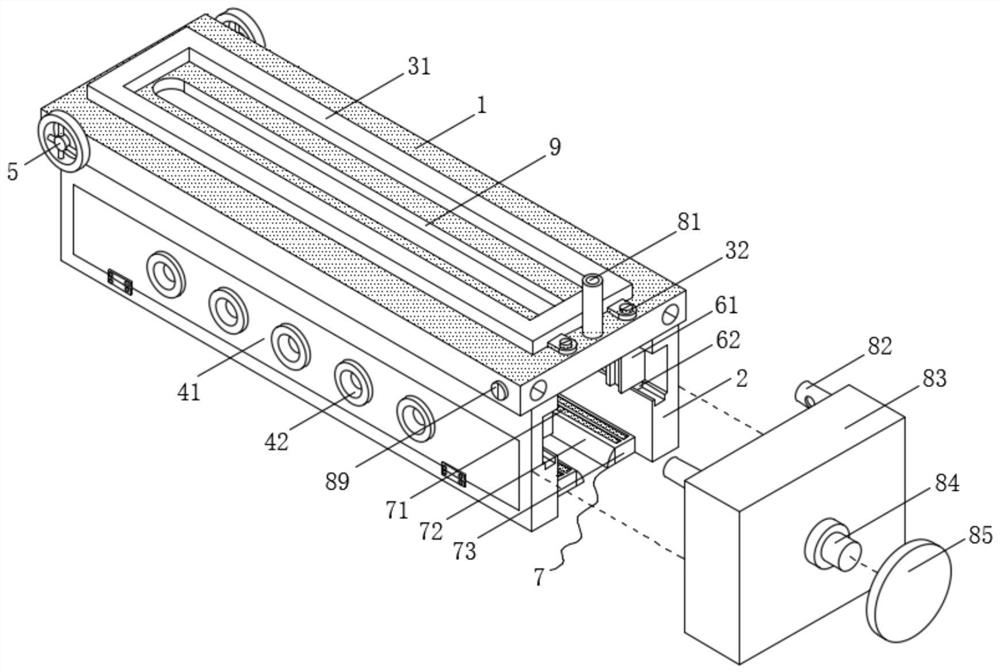

Laminated beam stirrup anti-inclination device with lightweight design

A lightweight design, anti-tilt technology, used in packaging, transportation and packaging, vehicles for freight, etc., can solve the problems of stirrup tilt, carriage impact, increase the damage rate of laminated beams, etc., to avoid fragmentation , Avoid friction, improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

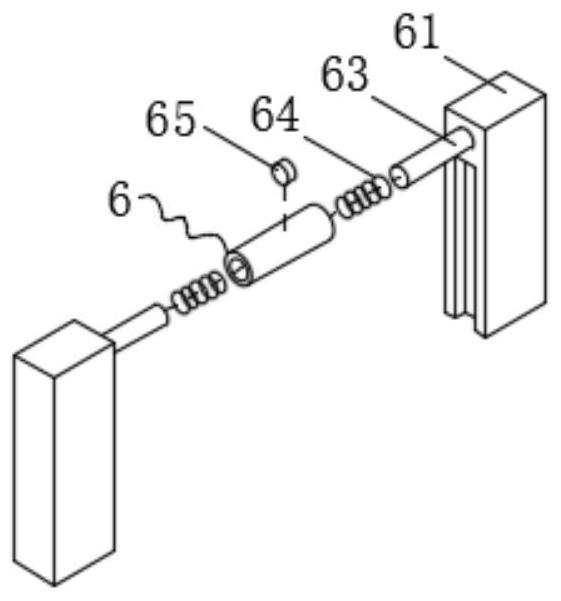

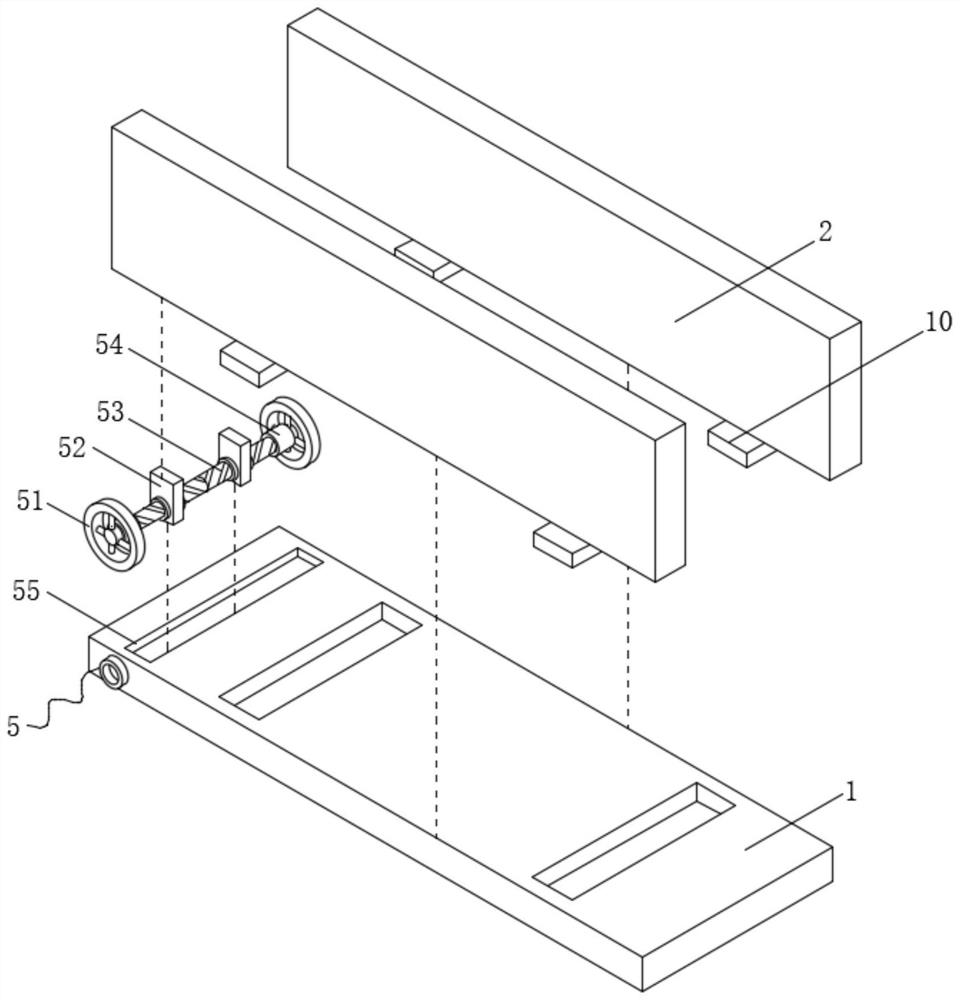

[0044] The specific embodiment is as follows: the first magnet block 48 and the second magnet block 49 are mutually adsorbed to fix the support plate 41, the support plate 41 will not be automatically disengaged when stored in the storage slot, and the support plate 41 is rotated to a horizontal position during transportation. Control the fixed rod 47 to rotate and control the first slide block 43 to move in the first chute at the same time, adjust the position of the hook 46 to allow the hook 46 to be hooked in the hanging ring 45, so as to achieve a stable fixing effect on the support plate 41. In the first spring 413 Under the action of elastic force, the connecting rod 414 leaves the push plate 415 and moves to the outside. When the push plate 415 is hit, it can drive the connecting rod 414 to squeeze the first spring 413. Under the elastic buffer effect of the first spring 413, the side plate 2 It can receive a good protection effect and prevent the composite beam from bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com