Injection sealed screen shell surface antifogging processing technology and product and video electronic device

A treatment process and screen surface technology, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, etc., can solve problems such as unsatisfactory anti-fog performance, reduce coating costs, and many dust spots, and achieve prevention Water mist condensation and electrostatic dust absorption, improve strength and pass rate, good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

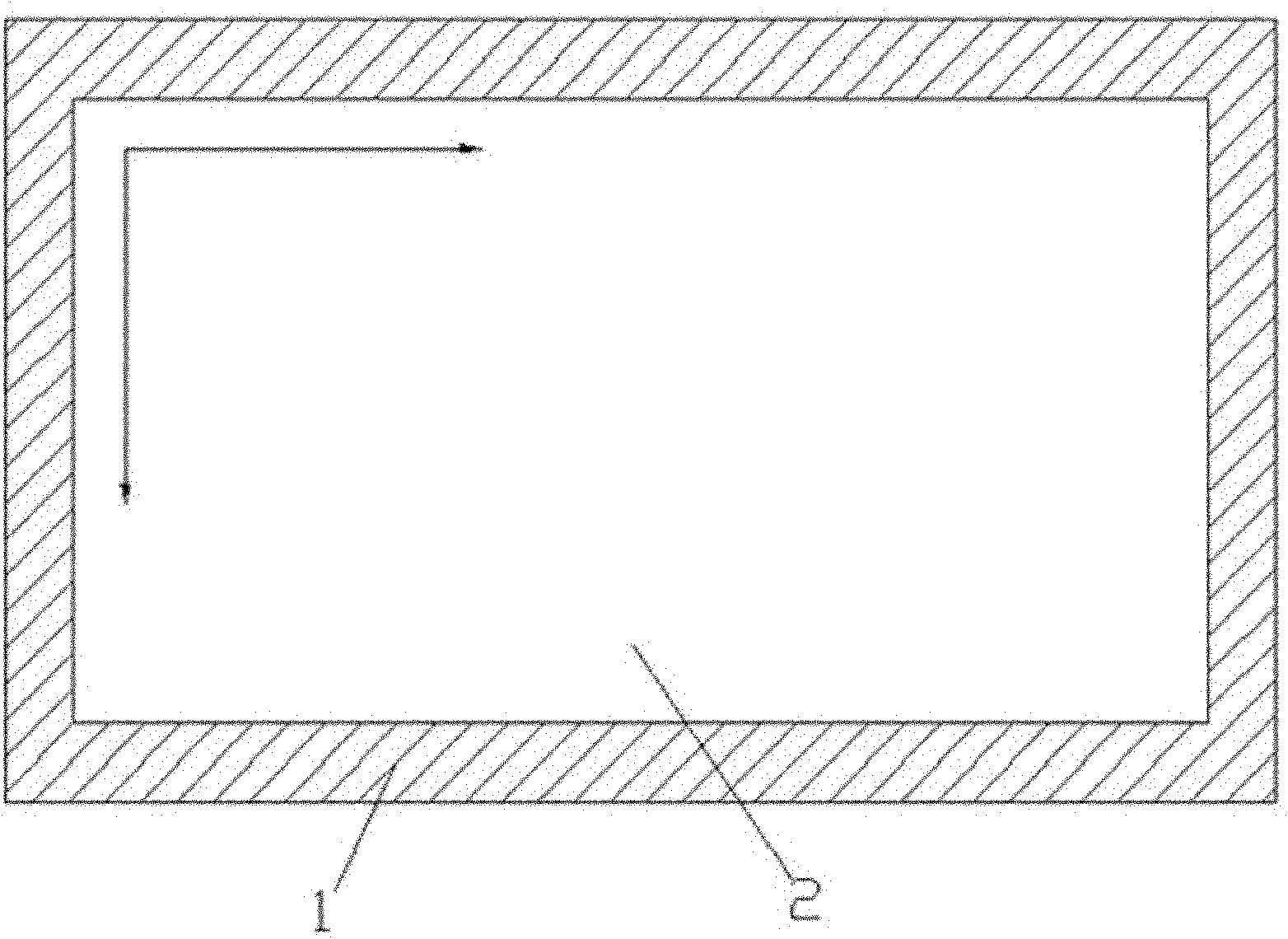

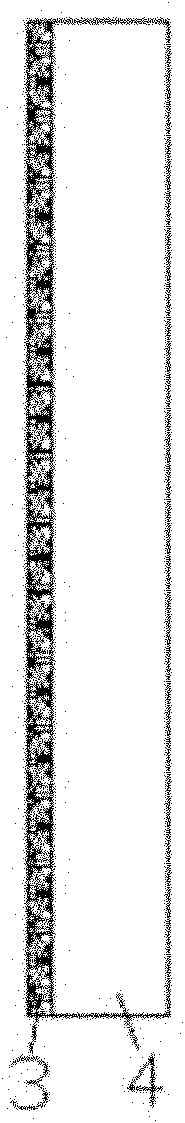

[0031] refer to figure 1 , figure 2 , now explain the surface process treatment of a TV injection molded screen cover, as shown in the figure, first use the spray masking tool 1 to cover the area that does not need to be sprayed on the cover 4, and the unshielded area is the spray area 2, and then Spraying is carried out, and finally a sprayed layer 3 is formed on the sprayed area 2 .

[0032] In this embodiment, an injection molding process is used to make the screen cover 4 of the TV set, and the material is polymethyl methacrylate (PMMA), also known as acryli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com