Method and device for preparing methyl chloride and ammonia by utilizing ammonium chloride and methyl alcohol

A technology for methanol preparation and methyl chloride, which is applied in the field of devices for preparing methyl chloride and ammonia, can solve the problems of corrosion of equipment by hydrogen chloride, block pipelines, and high energy consumption, and achieve the effects of large circulation, low consumption and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

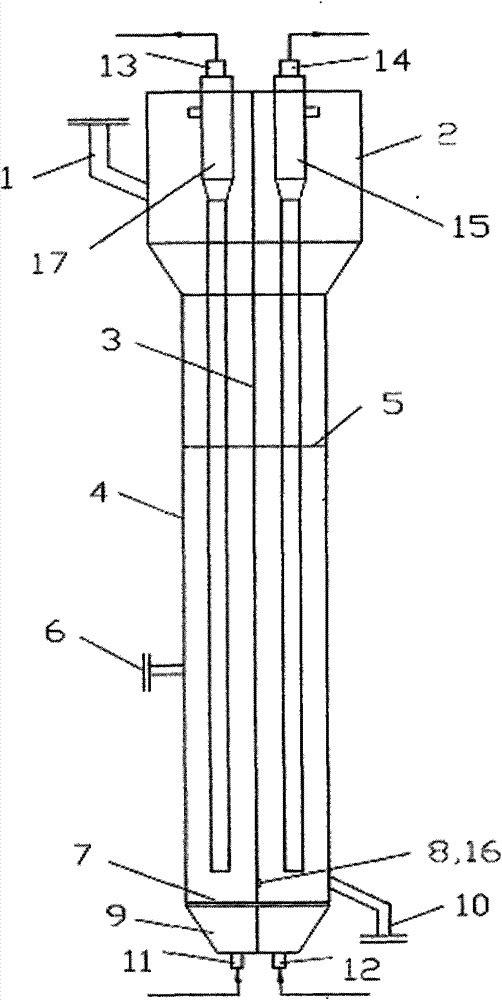

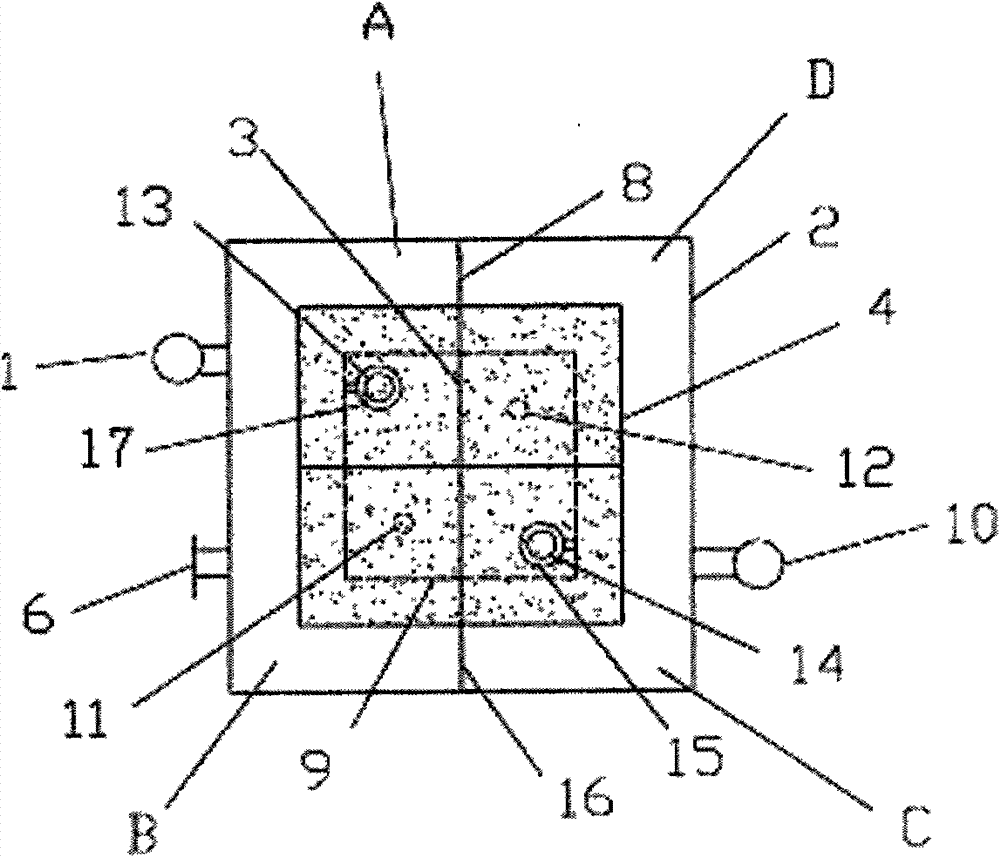

[0049] Using the device of the present invention, ammonium chloride and methanol are used to prepare methyl chloride and ammonia. Feed is ammonium chloride and methanol vapor, the ratio of the amount of the two substances is 0.85: 1; the temperature of the reaction zone is 320 ℃, the weight space velocity is 0.8 hours-1, and the superficial velocity of methanol vapor is 0.4 m / s, The flue gas superficial velocity is 0.3 m / s. After the reaction, the conversion rate of ammonium chloride was 99.3%, and the selectivity of methyl chloride was 83.2%.

Embodiment 2

[0051] Using the device of the present invention, ammonium chloride and methanol are used to prepare methyl chloride and ammonia. Feed is ammonium chloride and methanol vapor, the ratio of the amount of the two substances is 0.9: 1; the temperature of the reaction zone is 330 ℃, the weight space velocity is 0.85 hours-1, and the superficial velocity of methanol vapor is 0.5 m / s, The flue gas superficial velocity is 0.4 m / s. After the reaction, the conversion rate of ammonium chloride was 99.5%, and the selectivity of methyl chloride was 85.6%.

Embodiment 3

[0053] Using the device of the present invention, ammonium chloride and methanol are used to prepare methyl chloride and ammonia. Feed is ammonium chloride and methanol vapor, the ratio of the amount of the two substances is 0.9: 1; the temperature of the reaction zone is 340 ℃, the weight space velocity is 1.1 hours-1, and the superficial velocity of methanol vapor is 0.6 m / s, The flue gas superficial velocity is 0.5 m / s. After the reaction, the conversion rate of ammonium chloride was 100%, and the selectivity of methyl chloride was 89.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com