Method for smelting bell-less top blast furnace high proportion pellet ore burden structure

A smelting method and technology of charge structure are applied in the field of smelting high-proportion pellet charge structure of a bellless top blast furnace, and can solve the problems of restricting blast furnace production and improving technical and economic indicators, increasing resistance of blast furnace bolly gas soft melting zone, and affecting Blast furnace column permeability and other issues, to improve production stability and economic benefits, stabilize and uniform edge gas flow, and improve the quality of pig iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

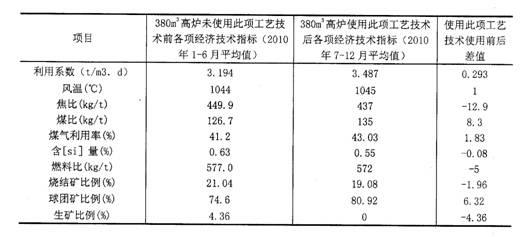

Examples

Embodiment Construction

[0018] A smelting method with a high-proportion pelletized ore charge structure for a bellless furnace top blast furnace. First, increase the alkalinity of the sintered ore to 2.5-3.5 times or add a flux with a high CaO content to meet the needs of the blast furnace slagging system; through the blast furnace batching and furnace The top charging process improves the air permeability of the center and edge of the blast furnace material column in the vertical direction to form two airflows; the theoretical combustion temperature of the tuyeres is controlled between 2200 ° C and 2300 ° C; the smelting is smelted with the operating guidelines of low silicon and low slag alkalinity. Under the condition of ensuring the smooth operation of the blast furnace, the utilization rate of gas is improved and the ratio of coke into the furnace is reduced.

[0019] The operation steps are as follows:

[0020] (1) Increase the alkalinity of the sintered ore to 2.5-3.5 times or add flux with hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com