High-temperature high-pressure gas-liquid two-phase corrosion simulated experiment device and experimental method thereof

A technology that simulates experimental devices and high temperature and high pressure. It is used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. It can solve the problems of simultaneous and online measurement, and achieve the effect of convenient use and simple connection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

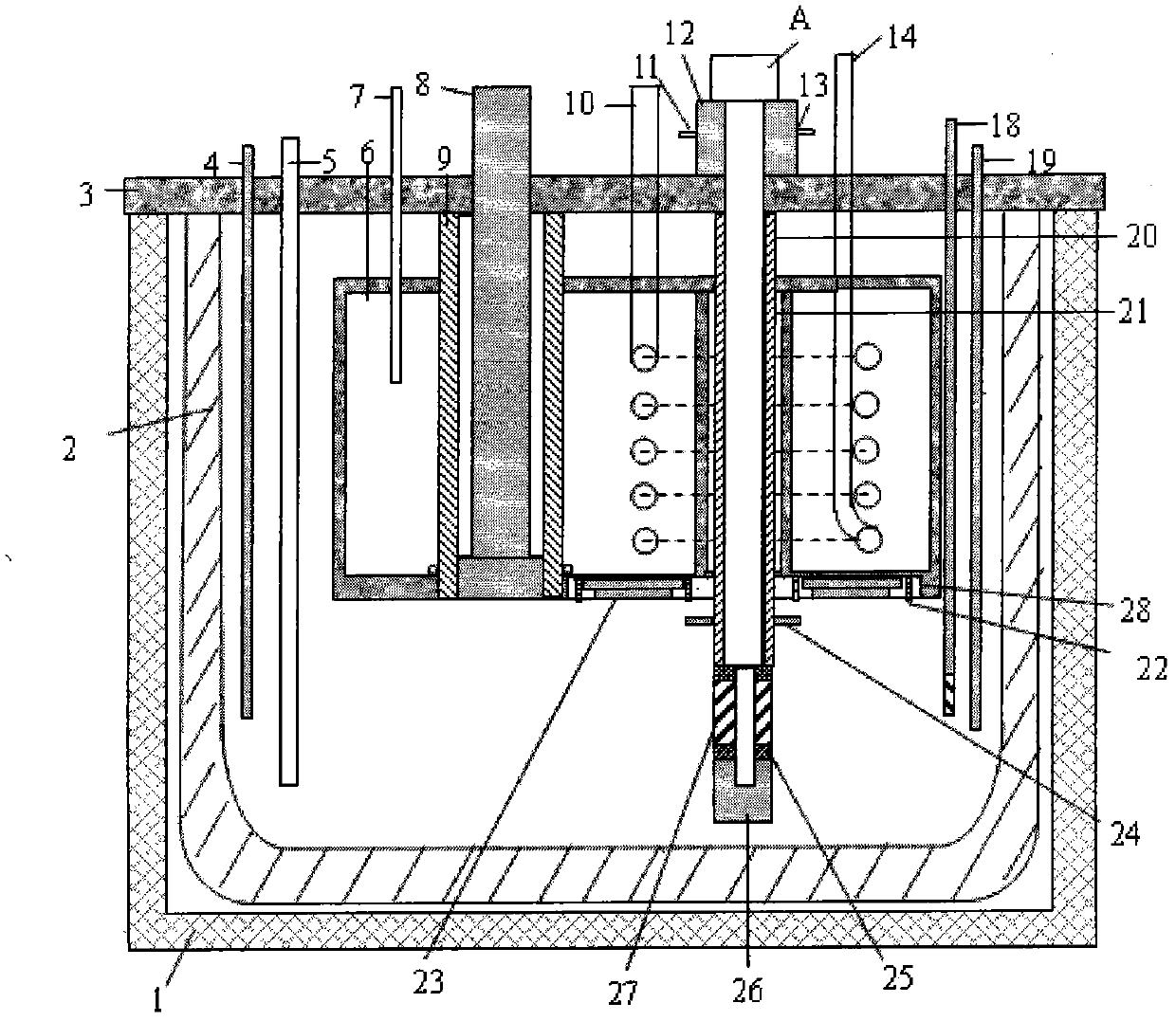

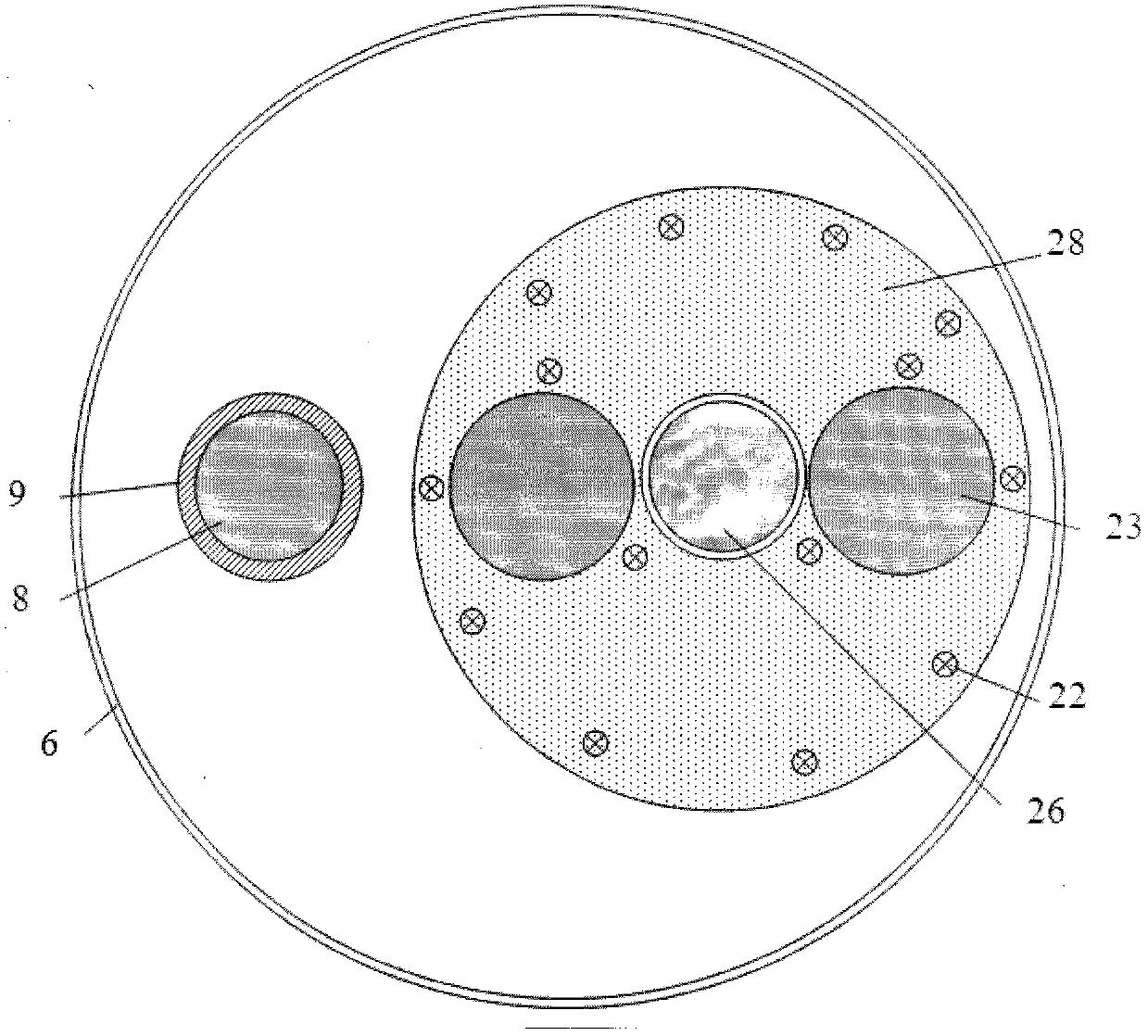

[0031] The invention provides a high-temperature and high-pressure gas-liquid two-phase corrosion simulation experiment device, which includes a thermal insulation heating device, a high-temperature and high-pressure reaction kettle, a first temperature-measuring resistor in the high-temperature and high-pressure reaction kettle, an upper cover of the high-temperature and high-pressure reaction kettle, and an air inlet pipe. The simulated experimental device also includes a condensation system, a liquid phase corrosion test system and a gas phase condensate corrosion test system.

[0032] The condensing system includes a condenser located in a high-temperature and high-pressure reactor, a second temperature-measuring resistor and a cooling water coil in the condenser.

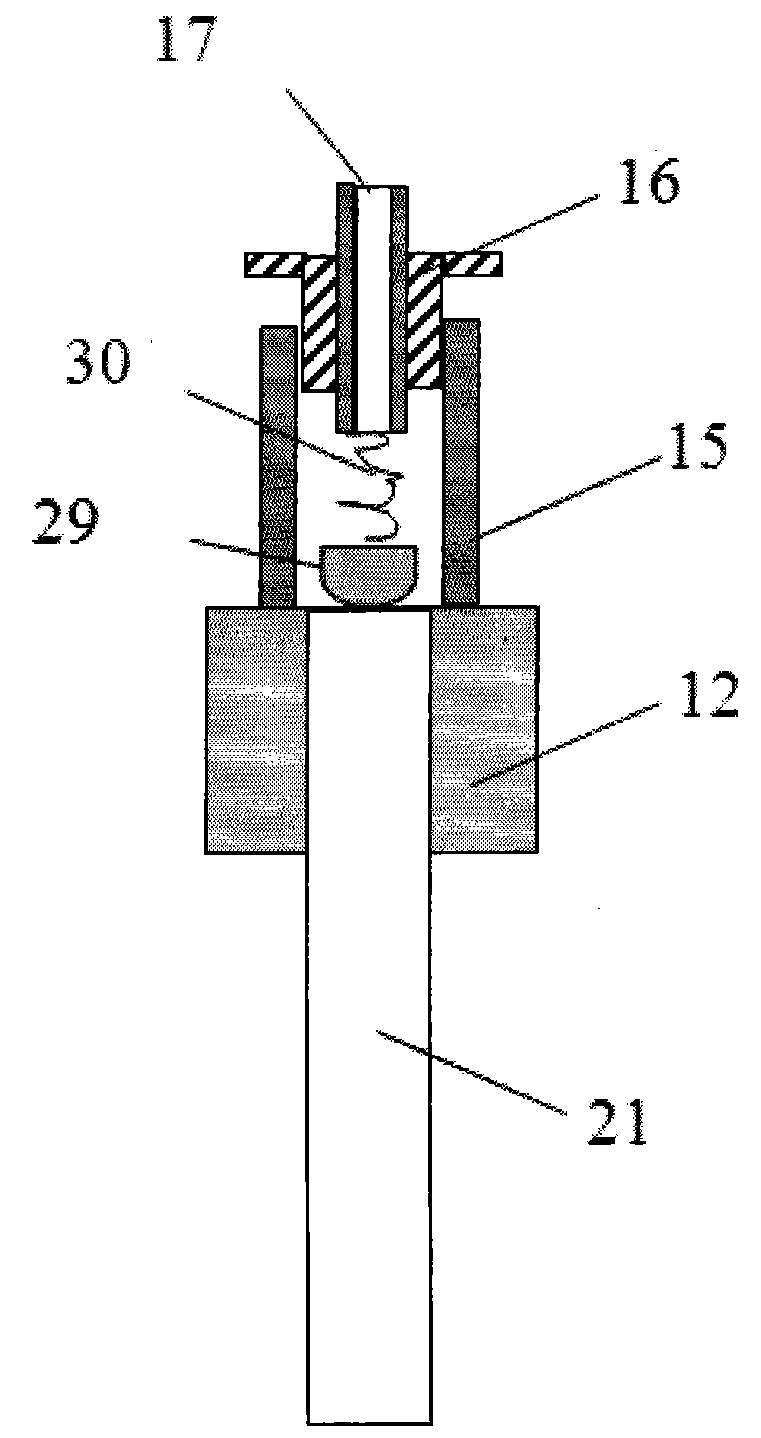

[0033] The liquid phase corrosion test system includes a magnetic drive device, a rotating shaft, a cylindrical electrode, an auxiliary electrode and a reference electrode, etc. The rotating shaft includes meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com