Retractable tunneling machine convenient for underground transport

A roadheader and telescopic technology, which is applied in the field of telescopic roadheaders, can solve the problems of fast loss of picks, inability of the cutting head to be retracted, and non-disassembly, etc., so as to reduce the loss of picks, facilitate the transportation of materials, and improve the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

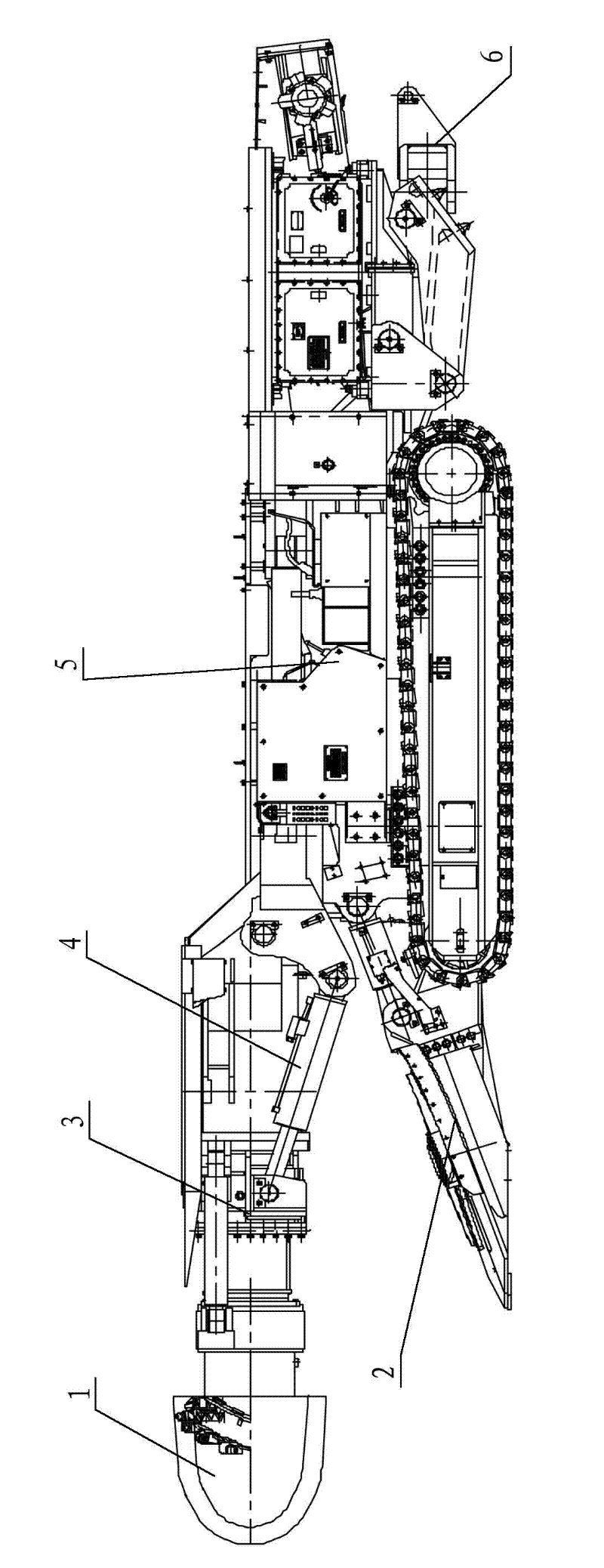

[0017] see figure 1 , the present invention includes a cutting head telescopic section 1, a shovel plate 2, a cutting reducer box 3, a body 5, a rear support 6, and a first conveyor 8, and is characterized in that:

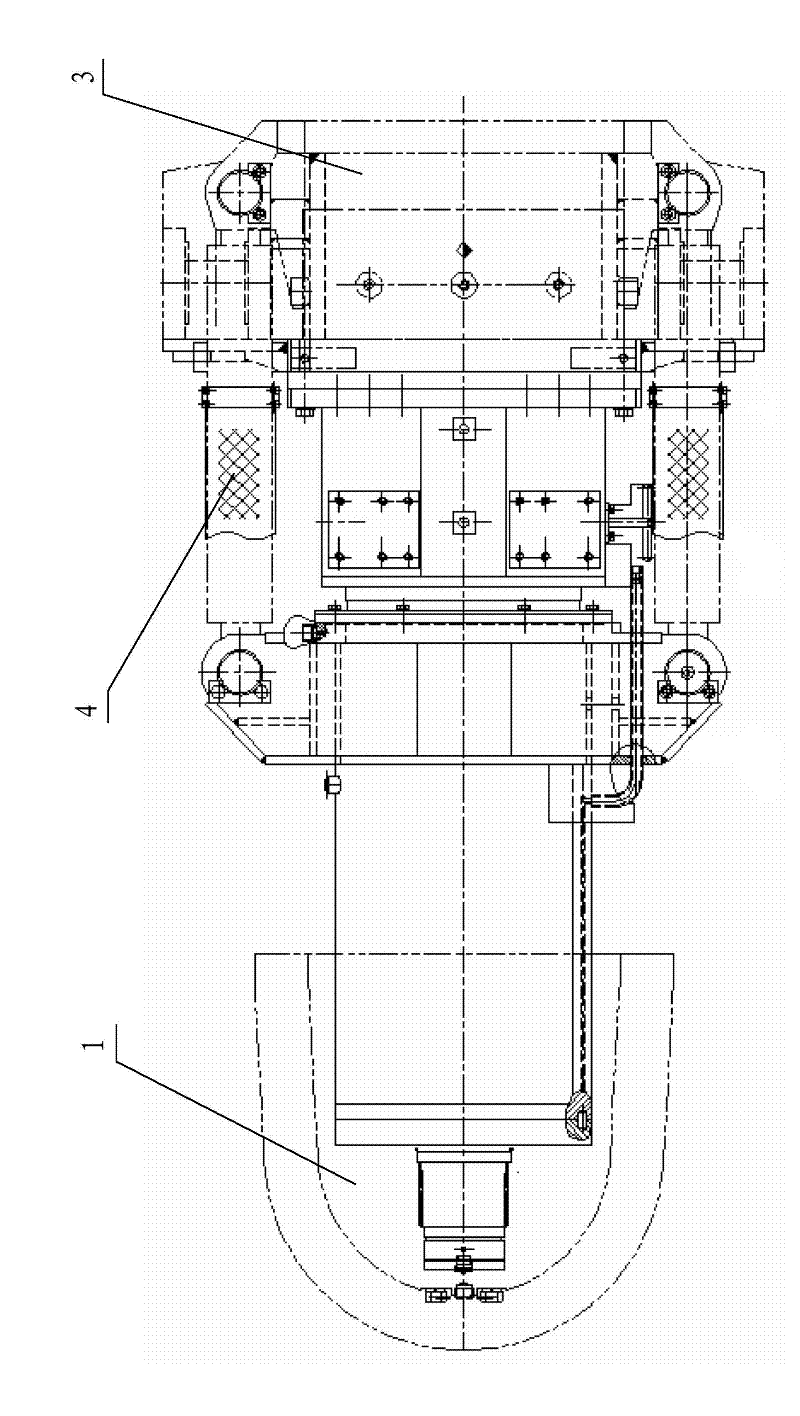

[0018] see figure 2 , the cutting reducer casing 3 is connected with the cutting head telescopic section 1 through two hydraulic cylinders 4, that is, the cylinder bodies of the two hydraulic cylinders are fixed on the cutting reducer casing, and the piston rod of the hydraulic cylinder is fixed on the cutting head telescopic section, so that The cutting head is retractable, which is good for cutting hard rock;

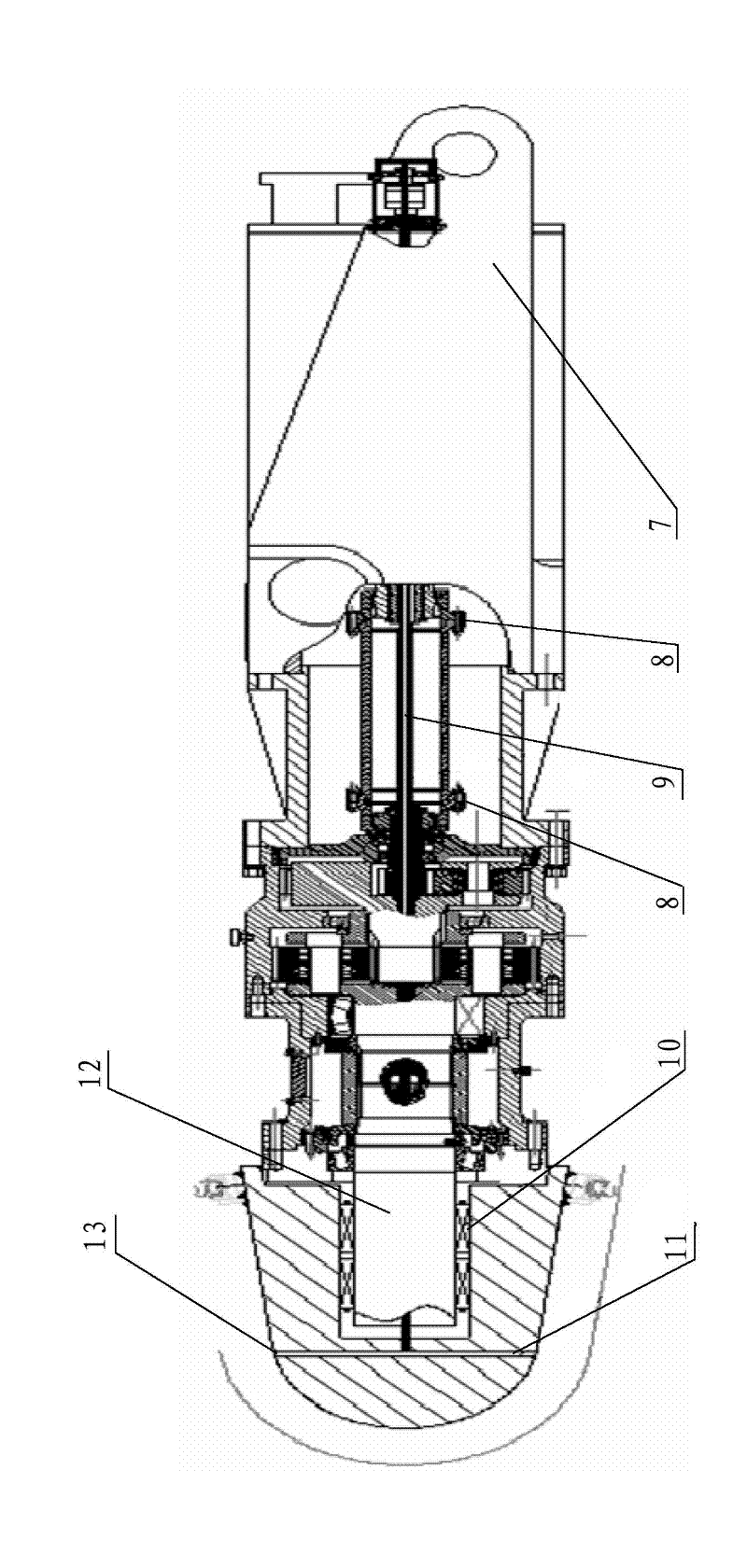

[0019] see image 3 , the special waterway 11 for high-pressure water is set at the cutting head, and high-pressure water is used to assist cutting. Specifically, the cutting part processes coaxial round holes in sections from the tail end 7 of the motor to the head end of the main shaft 12. In the round holes, one can withstand a pressure higher than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com