Solid-phase decarburization method of high-carbon Fe-Mn alloy

A technology of high-carbon ferromanganese and ferromanganese alloy, which is applied in the field of solid-phase decarburization of high-carbon ferromanganese alloy, can solve the problems of poor comprehensive effect of decarburization, low decarbonization efficiency, and high energy consumption of decarbonization, so as to reduce energy consumption , fast decarburization speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

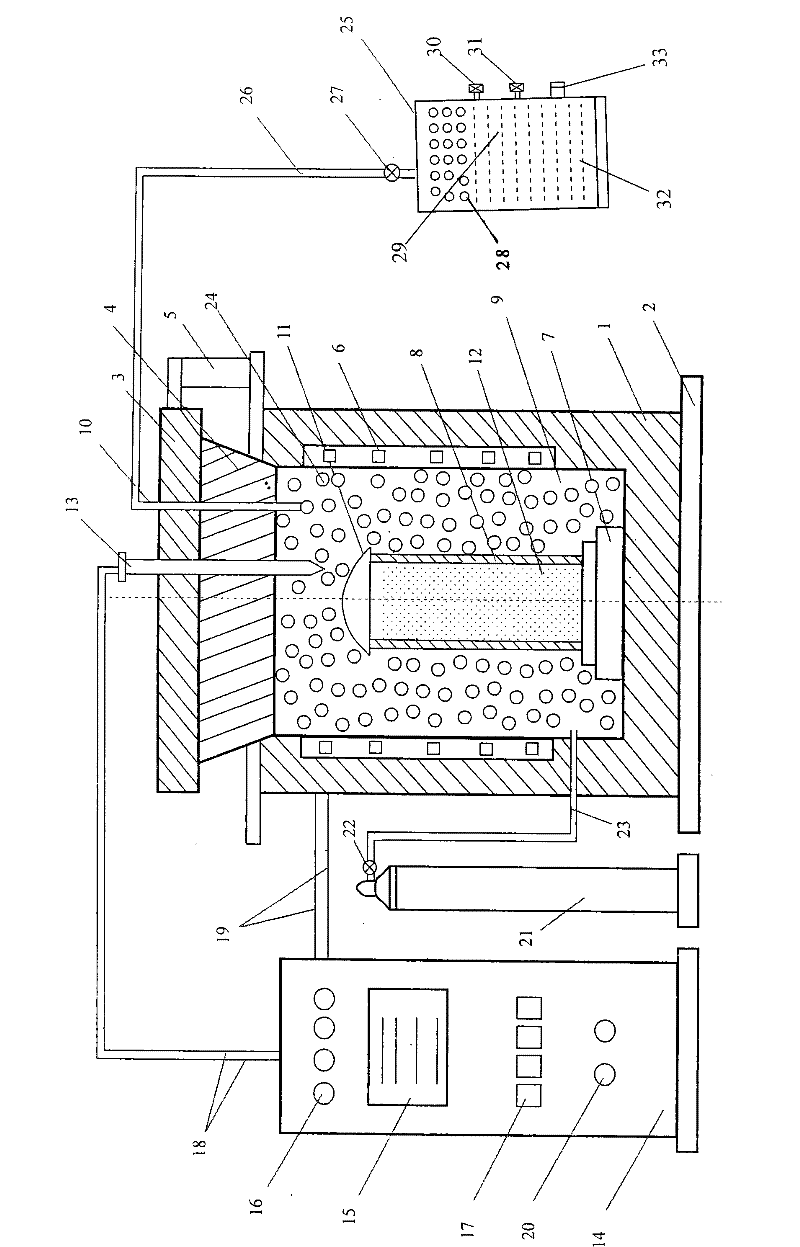

[0067] The present invention will be further described below in conjunction with the accompanying drawings:

[0068] figure 1 As shown, it is the state diagram of microwave heating solid-phase decarburization, and the positions of each part should be correct and operate in sequence.

[0069]The preparation is carried out in a microwave heating solid-phase decarburization furnace. The lower part of the microwave decarburization furnace 1 is the furnace seat 2, the upper part is the sealing cover 4 and the furnace cover 3, and the opening and closing are controlled by the opening and closing frame 5. 3. The sealing cover 4 is provided with a thermocouple 13, an air hole 10, a microwave generator 6 is provided on the furnace wall of the microwave decarburization furnace 1, and the microwave generator 6 is a furnace cavity 9 in the microwave decarburization furnace 1, In the middle and lower part of the furnace cavity 9 is the crucible seat 7, in the upper part of the crucible se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com