Device and method for separating residue from catalytic cracking oil slurry

A technology for catalytic cracking of oil slurry and residues, which is applied in the petrochemical field and can solve the problems of filter blockage, easy blockage of the filter, and inability to achieve complete separation of liquid and solid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

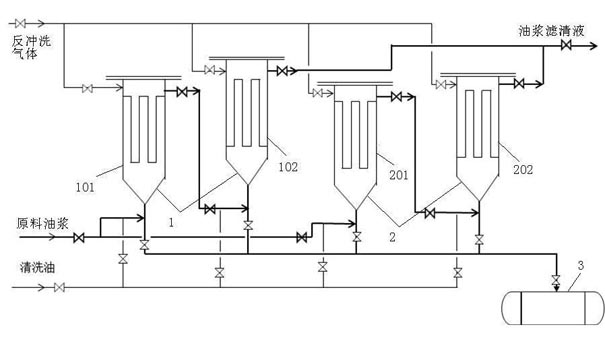

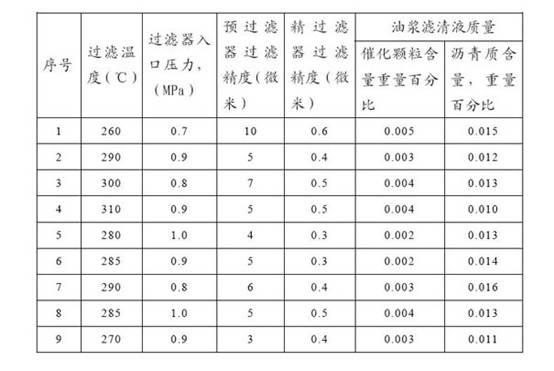

[0036] Such as figure 1 As shown, a device for separating residues from catalytic cracking oil slurry using the process method of the present invention includes two sets of filter sets. The first filter set 1 is composed of a pre-filter 101 and a fine filter 102 connected in series. The top of filter 101 is provided with a pre-filtered oil outlet, and this pre-filtered oil outlet is connected to the bottom of fine filter 102, and the second filter group 2 is made up of pre-filter 201 and fine filter 202 connected in series, pre-filter The top of 201 is provided with a pre-filtered oil outlet, and the pre-filtered oil outlet is connected to the bottom of fine filter 202 . Filter cake tank 3 is arranged on the bottom of prefilter 101,201 and fine filter 102,202, is used to hold the filter cake after stripping and the cleaning oil after cleaning; There is a raw material oil slurry inlet and a cleaning oil inlet, and the bottom end of the fine filter 102, 202 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com