Paint composition and preparation and using methods thereof

A composition and coating technology, which can be applied to epoxy resin coatings, coatings, devices for coating liquid on surfaces, etc. The effect of adhesion and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

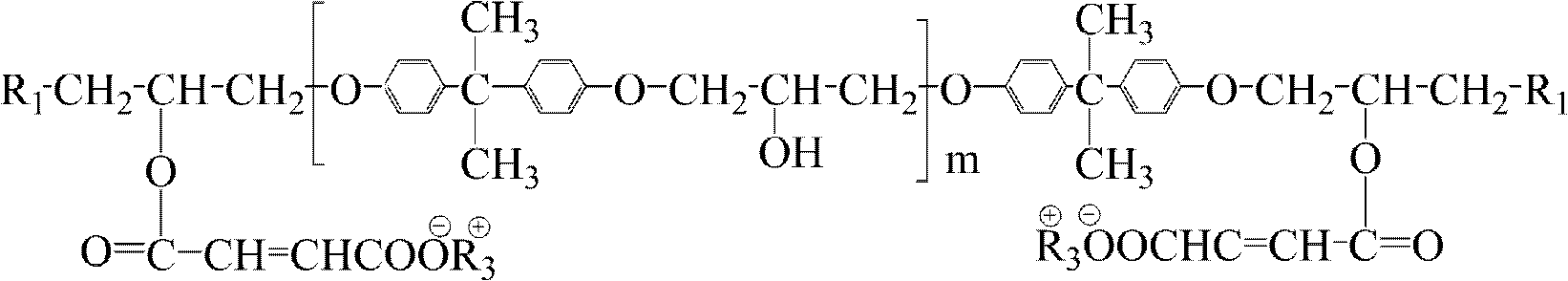

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a preparation method of the above-mentioned coating composition, comprising:

[0056] Add water-based epoxy acrylate, photoinitiator and cross-linking agent to the auxiliary agent under stirring state, and then filter.

[0057] Concrete preparation process is preferably as follows:

[0058] a) Put the leveling agent and defoamer in the mixer and mix evenly, set the stirring speed to 700rpm-900rpm, stir for 10min-20min, add water-based epoxy acrylate, and increase the stirring speed to 1200rpm-1400rpm and stir 2h~4h.

[0059] b) Add co-solvent, photoinitiator and water-based crosslinking agent to the mixture obtained in step a, set the stirring speed to 1400rpm-1600rpm, stir for 25min-40min and then filter with a 200-mesh filter to obtain a water-based epoxy acrylate coating.

[0060] The using method of coating composition provided by the invention is as follows:

[0061] After the coating composition is sprayed on the surface of t...

Embodiment 1~ Embodiment 6

[0075] The coating composition of above-mentioned 6 embodiments all is to prepare according to the following method:

[0076] 1. Add the leveling agent and defoamer to the paint tank, set the stirring speed to 800rpm, stir for 15 minutes, add water-based epoxy acrylate, set the stirring speed to 1300rpm, and stir for 2.5 hours.

[0077] 2. Add a cosolvent, a photoinitiator and a crosslinking agent to the mixture obtained in step 1, set the stirring speed to 1500 rpm, stir for 30 minutes, and filter with a 200-mesh filter to obtain a coating composition.

[0078] Above-mentioned 6 embodiment raw materials and consumption are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com