Electrocatalysis particle for treating cyanide-containing waste water and method for treating cyanide-containing waste water

A technology of catalytic particles and electrocatalysis, which is applied in the field of water treatment, can solve the problems of low current efficiency, high operating cost, and insufficient economy of electrolysis, and achieve the effects of low preparation cost, high mechanical strength, and improved treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Calculated by weight percentage, with 42% activated carbon as the matrix, 14% iron oxide, 23% copper oxide, 4.5% manganese oxide, 1.2% zinc oxide, 0.6% zirconia, 0.7% cerium oxide as the initiator, and 14% wood Calcium sulfonate is used as the binder and mixed with water, then extruded and cut into pellets, then air-dried, and finally heated and carbonized and activated for 3 hours under the condition of 470°C and anoxic, and made into particles with a particle size of 4-6mm. Electrocatalytic particles for cyanide removal.

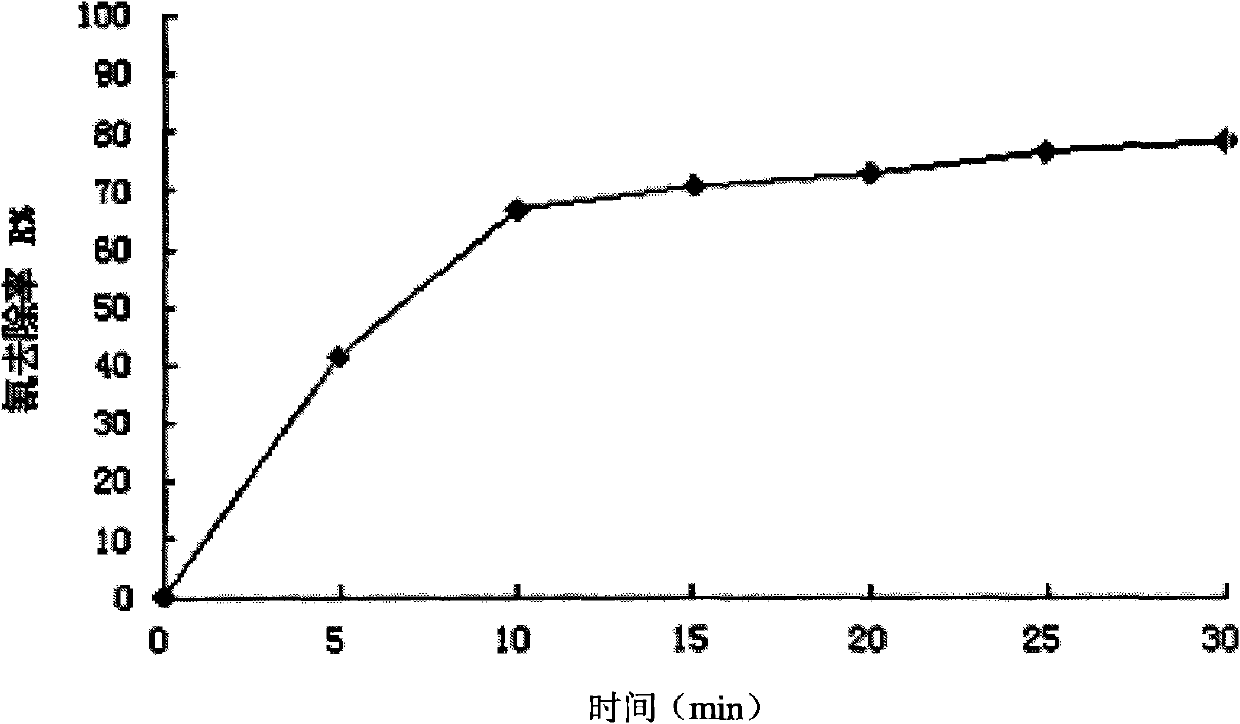

[0029] The synthesized electrocatalytic pellets for cyanide removal are subjected to an air flow rate of 1000L / h, a pulsed DC voltage of 30V, a pH of 9.5, a volume of cyanide-containing wastewater of 200L, and a reaction time of 5, 10, 15, 20, 15, and 30 minutes respectively. Under the conditions, to the cyanide concentration being 196mg / L waste water, carry out gap type static experiment ( figure 2 ); and under the same conditions, with the treat...

Embodiment 2

[0031] Under the condition of the same electrocatalytic particle for cyanide removal (electrocatalytic particle of the present invention), and at an air flow rate of 1000L / h, the treatment capacity is 200L / hr, the mass ratio of electrocatalytic particle to waste water is 1:2, and the waste water is The residence time in the catalytic cell is 30 minutes, the cathode electrode material in the electrocatalytic cell is stainless steel, the anode electrode material is graphite, the distance between the electrodes is 60cm, and the applied pulse DC voltage of the electrodes is 30 volts. Under conditions, the cyanide-containing wastewater is treated (total cyanide concentration 170-200mg / L, pH 9.0-11.0), respectively adopting a wastewater treatment device (electrocatalytic particle circulation cleaning device) as used in Chinese patent CN200920263896.7, and adopting Compared with the traditional device (without the function of electrocatalyst particle circulation cleaning), the on-site...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com