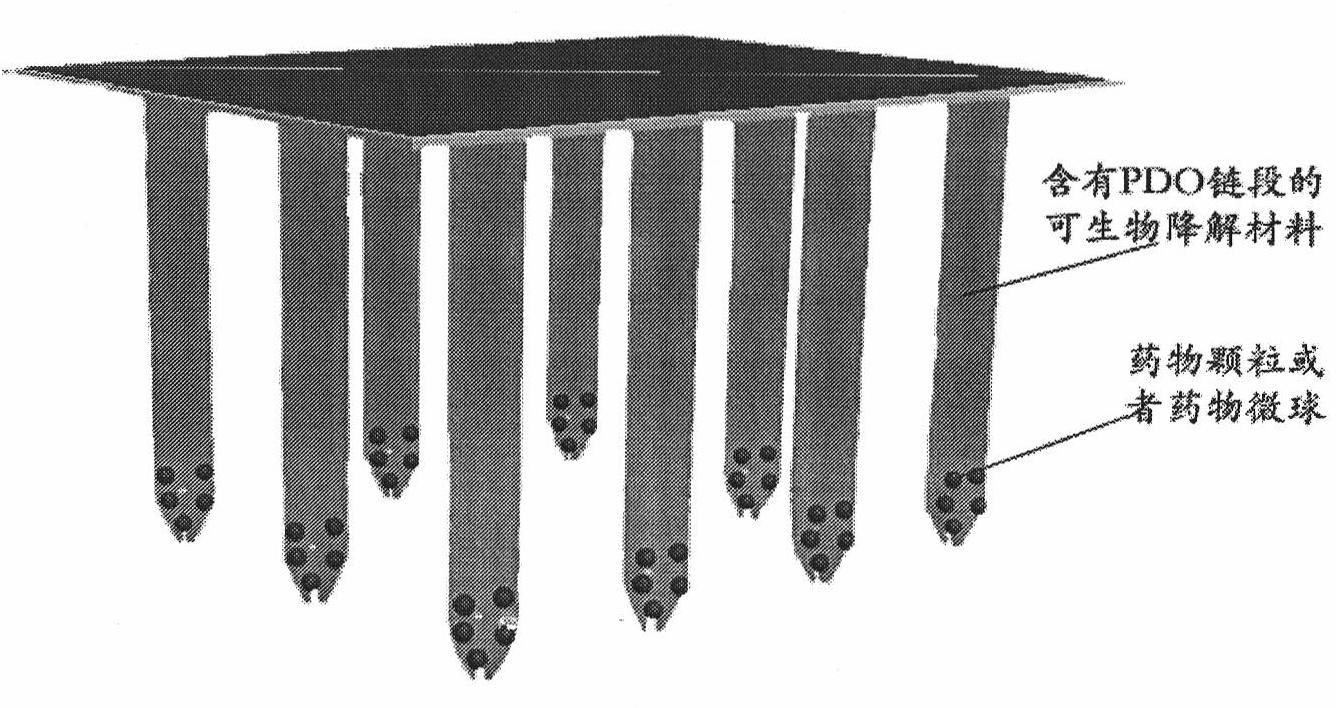

Novel micro-needle patch containing degradable polymer and preparation method thereof

A technology of polymer and micro-needle patch, applied in the field of medicine, can solve the problems of a single variety of biodegradable polymers and the inability to meet the requirements of controlled release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the P (PDO-LA) (95: 5) microneedle patch of preparation bovine serum albumin (BSA)

[0019] The mold for preparing the microneedles was cleaned, dried in an oven, and then placed on a petri dish. Disperse 50mg of bovine serum albumin (BSA) powder in acetonitrile at a concentration of 10% (w / v), sonicate, mix, and filter so that the particle size of bovine serum albumin (BSA) powder is 1-30 μm; Disperse in acetonitrile so that the concentration is 20% (w / v); then pour it into a polydimethylsiloxane (PDMS) elastomer mold, dry under reduced pressure for 2-5 minutes, and completely evaporate the solvent. Clean up the bovine serum albumin (BSA) powder remaining on the outside of the mold, then melt 1.0g of P(PDO-LA) (95:5) polymer, and pour it into the above PDMS mold under high temperature and vacuum conditions (110oC, -70kPa), Continue for 10-20 minutes, and then cool to room temperature, then the microneedle patch can be taken out from the mold to prepare a...

Embodiment 2

[0020] Example 2: Preparation of P(PDO-LA) (95:5) microneedle patch of risperidone microspheres

[0021]Dissolve 50mg risperidone and 0.2g P(PDO-LA) (5:95) in a mixed solution of dichloromethane and methanol, stir to dissolve, slowly drop this solution into 2mL PVA aqueous solution (10%), and Stir while adding dropwise, and stir at high speed for 5 minutes after the dropwise addition is completed; then slowly add this emulsion into 50 mL of PVA solution with a concentration of 2%, stir while adding dropwise, at a speed of 200 r / min, stir for 4 hours, and volatilize the organic solvent to make it solidified. Then centrifuge, wash, and freeze-dry to obtain microspheres with a particle size of 20-50 μm. The microspheres were placed in a clean PDMS mold, and then 1.0g of P(PDO-LA) (95:5) polymer was melted and poured into polydimethylsiloxane under high temperature vacuum conditions (110oC, -70kPa) (PDMS) elastomer mold for 10-20 minutes, and then cooled to room temperature, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com