Multi-edge pipe combined wind power tower

A combined, ribbed tube technology, applied in wind power generation, wind turbines, wind turbine components, etc., can solve the problems of persistently high wind power prices, difficult construction and installation, and huge production equipment, achieving low maintenance costs and savings Great, light-weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

illustration:

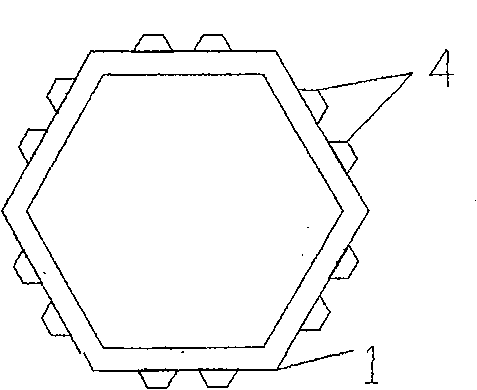

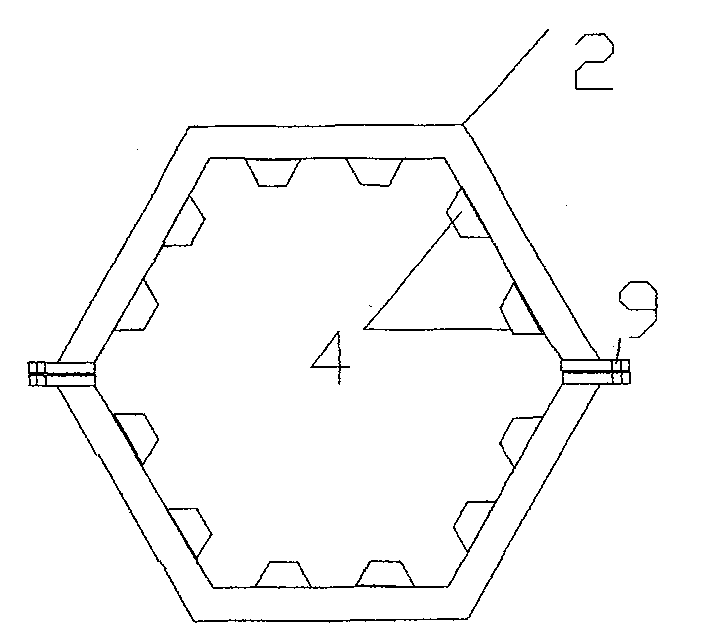

[0021] 1. Internal fasteners

Embodiment

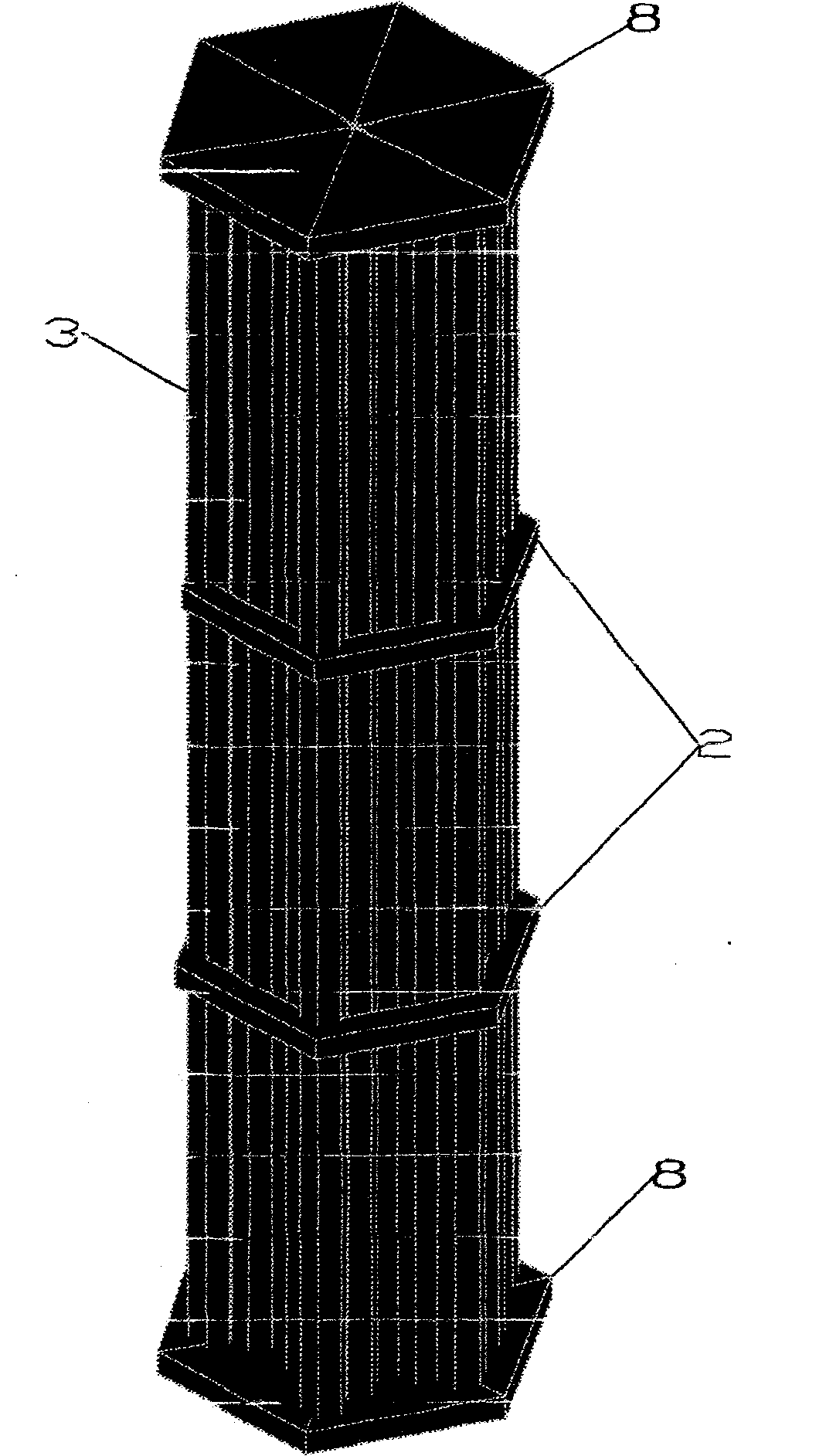

[0023] As shown in the figure, the embodiment of the present invention provides a hexagonal tube combined wind power tower with good rigidity and light weight. First, fix the internal fasteners 1 on the mould, according to the number of internal fasteners 1 required by the design rigidity requirements of the product; secondly, protect the internal fasteners of different materials and wall thicknesses selected according to the needs of the product. The pipe 4 is fixed on the inner fastener 1; then the hexagonal galvanized steel pipe 3 of different materials and wall thicknesses selected according to the needs of the product is cut into a certain length, and the arranged rings are sequentially combined and placed in the inner fastener. Firmware protective tube 4; then the outer fastener protective tube 5 is placed and fixed between each hexagonal galvanized steel pipe 3 in sequence, and the outer fastener protective tube 5 is hooped with the outer fastener 2, from The screw hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com