Perovskite structure-based single-phase iron-based superconductive material and preparation method thereof

A technology of perovskite structure and superconducting materials, applied in the field of superconducting materials and their preparation, can solve the problems of no superconductivity, etc., achieve good superconducting stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

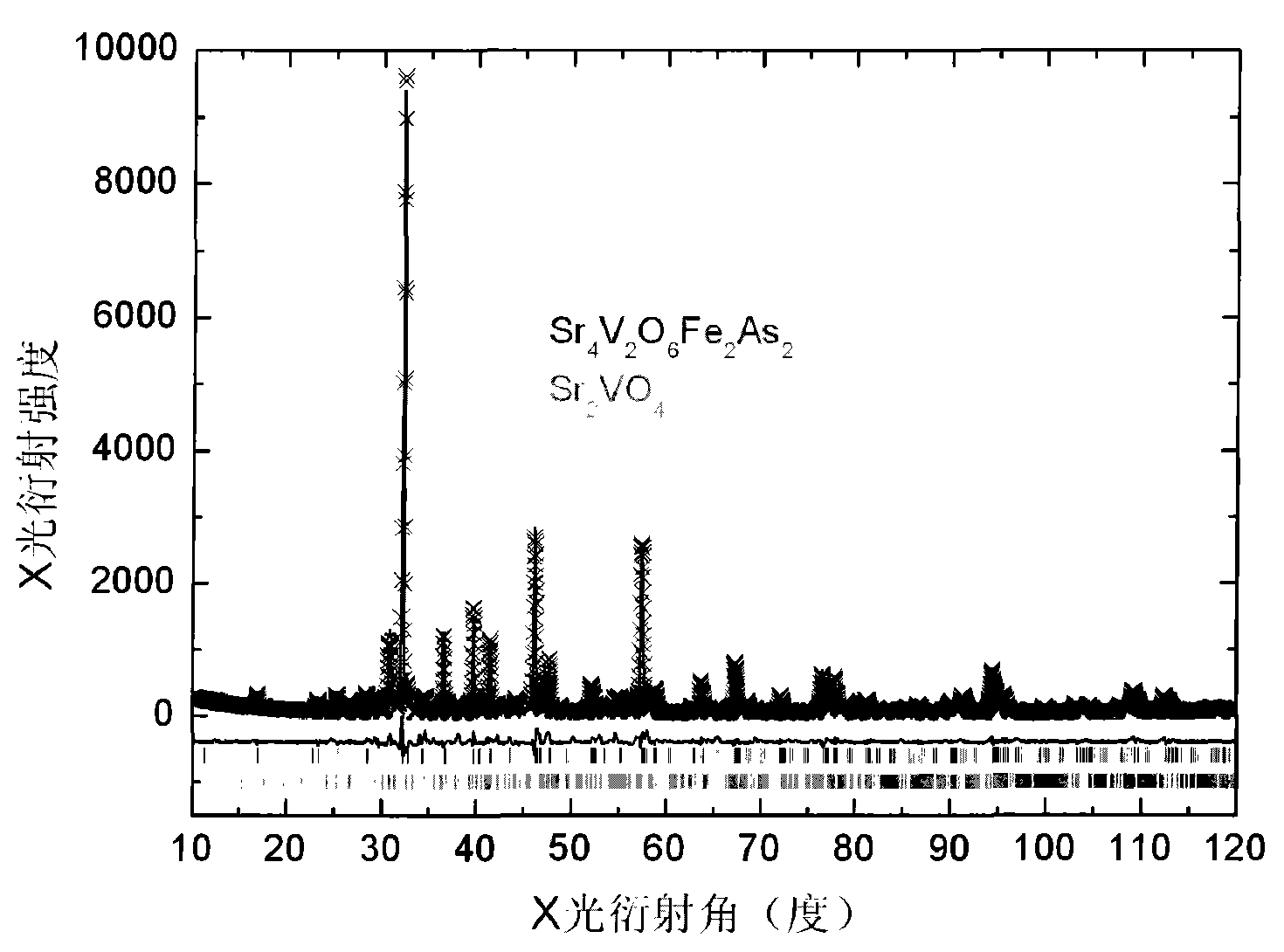

[0030] Synthesis of superconducting material Sr by solid-state reaction method 4 V 2 o 6 Fe 2 As 2 . The operation steps are as follows

[0031] 1) Step 1:

[0032] a. Preparation of SrAs precursor: adopt solid-state reaction method, this solid-state reaction method comprises quartz glass tube sealing method or high-melting point metal sealing method; As particles with 99.5% purity and Sr particles with 99%-99.99% purity are mixed with 1 : 1 molar ratio mixing and grinding, then the mixed and ground raw materials are pressed into small discs with a diameter of 10mm, wherein the tablet pressure is 2Mpa; sealed in a high vacuum (about 10 -5 Pa) in a quartz tube or a high-melting-point metal tube, first slowly raise the temperature to 500°C for 12 hours, then sinter at 680°C for 10 hours, and then slowly cool down to room temperature to obtain the SrAs compound;

[0033] b. Preparation of FeAs precursor: weigh As particles and Fe powder at a molar ratio of 1:1; grind and m...

Embodiment 2

[0039] Using V 2 o 5 Synthesis of Superconducting Material Sr by Solid State Reaction with Precursors 4 V 2 o 6 Fe 2 As 2 . The operation steps are as follows

[0040] 1) Step 1:

[0041] a. Preparation of SrAs precursor: adopt solid-state reaction method, this solid-state reaction method comprises quartz glass tube sealing method or high-melting point metal sealing method; As particles with 99.5% purity and Sr particles with 99%-99.99% purity are mixed with 1 : 1 molar ratio mixing and grinding, and then pressed into a small disc with a diameter of 10mm, wherein the tablet pressure is 3Mpa, 4Mpa or 6Mpa; sealed in a high vacuum (about 10 -5 Pa) in a quartz tube or a high melting point metal tube, first slowly raise the temperature to 500°C for 12 hours, then sinter at 680°C or 750°C for 7, 8, 9 or 10 hours, and then slowly cool down to room temperature , to obtain the SrAs compound;

[0042] Among them, the particle size of As particles and Sr particles is 100 mesh,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com