Red phosphor powder for white LED as well as preparation method and application thereof

A technology of red fluorescent powder and fluorescent powder, which is applied in chemical instruments and methods, luminescent materials, and the use of gas discharge lamps. It can solve the problems of easy decomposition, unstable chemical properties, and low luminous efficiency, and achieve stable physical and chemical properties. , Wide range of excitation wavelengths, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

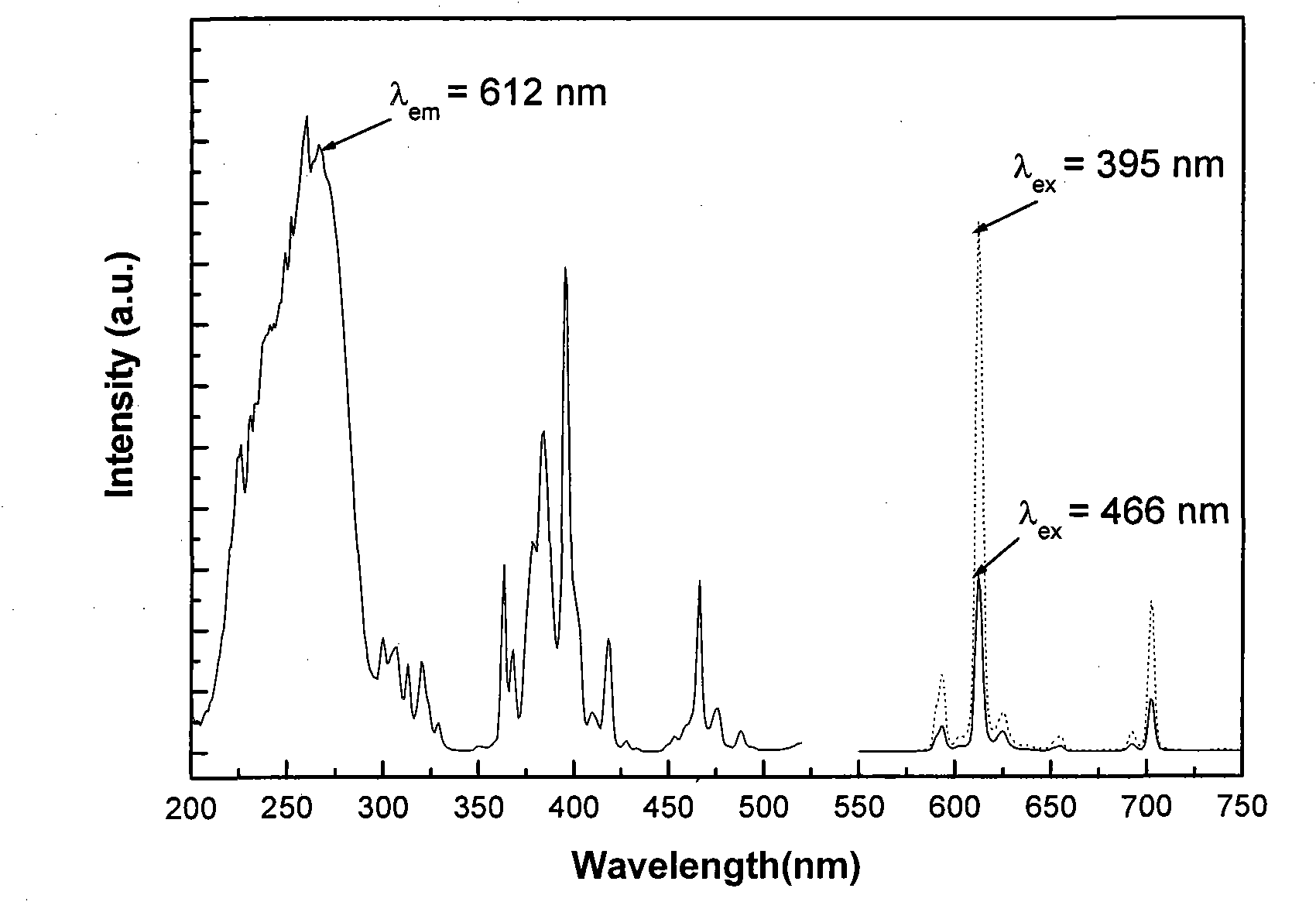

[0037] Example 1: LiGd 0.80 Nb 2 o 7 : 0.20 Eu 3+ Preparation example of phosphor powder.

[0038] Weigh 0.3688 g Li respectively 2 CO 3 (analytical pure), 1.4474 g Gd 2 o 3 (99.999%), 2.6533 g Nb 2 o 5 (99.999%), 0.3513 g Eu 2 o 3 (99.999%), grind and mix evenly in an agate mortar, put it into an alumina crucible, bake at 1200 ° C for 5 hours, cool to room temperature with the furnace, and grind to obtain LiGd in the present invention. 0.80 Nb 2 o 7 : 0.20 Eu 3+ red phosphor. Its excitation and emission spectra are shown in figure 1 .

Embodiment 2

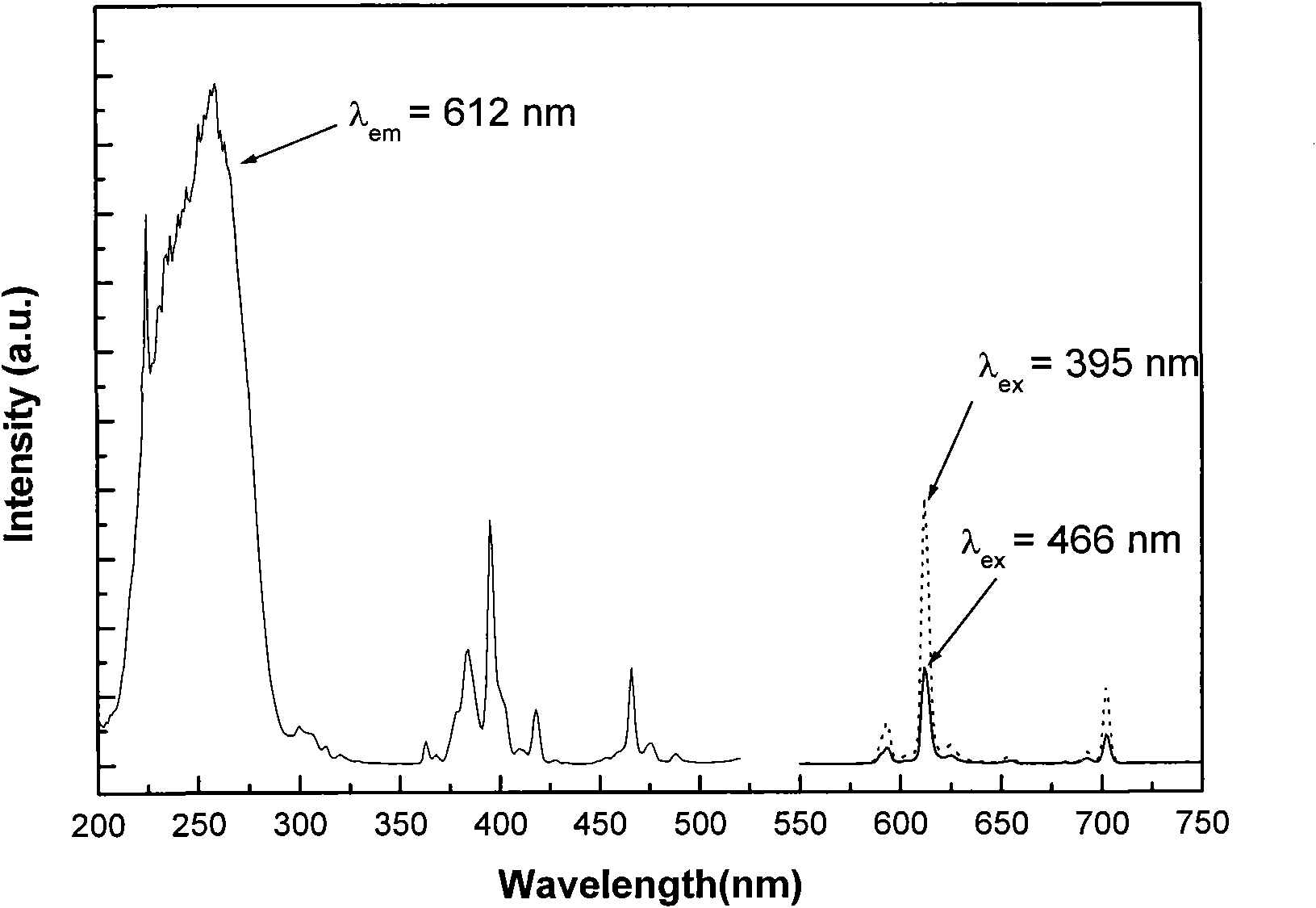

[0039] Example 2: NaGd 0.80 Nb 2 o 7 : 0.20 Eu 3+ Preparation example of phosphor powder.

[0040] Weigh 0.5126 g of Na respectively 2 CO 3 (analytical pure), 1.4024 g Gd 2 o 3 (99.999%), 2.5709 g Nb 2 o 5 (99.999%), 0.3404 g Eu 2 o 3 (99.999%), ground and mixed evenly in an agate mortar, put it into an alumina crucible, baked at 1200°C for 5 hours, cooled to room temperature with the furnace, and ground to obtain NaGd in the present invention. 0.80 Nb 2 o 7 : 0.20 Eu 3+ red phosphor. Its excitation and emission spectra are shown in figure 2 .

Embodiment 3

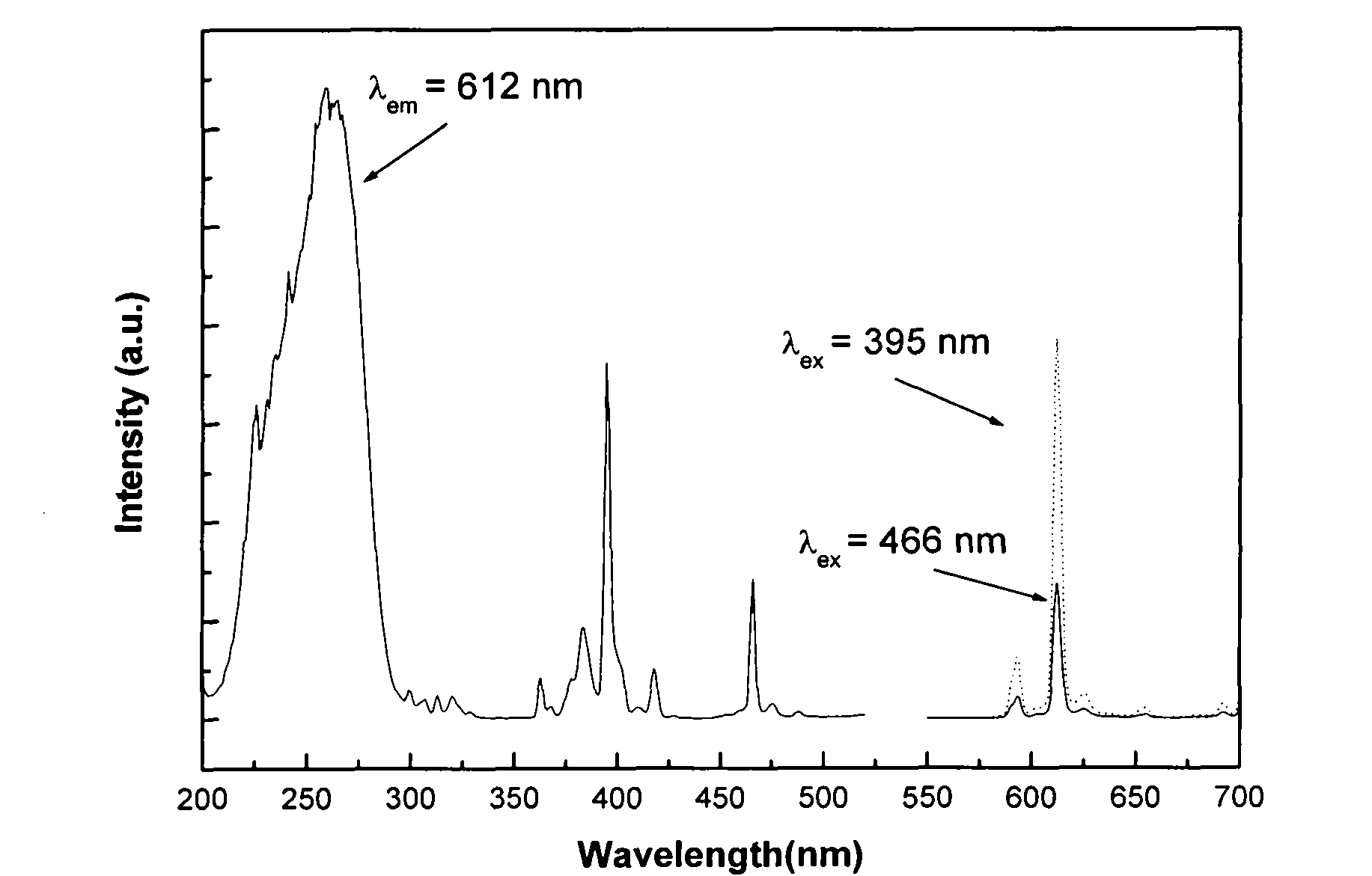

[0041] Example 3: KGd 0.80 Nb 2 o 7 : 0.20 Eu 3+ Preparation example of phosphor powder.

[0042] Weigh 0.6482 g of K 2 CO 3 (analytical pure), 1.3600 g Gd 2 o 3 (99.999%), 2.4932 g Nb 2 o 5 (99.999%), 0.3301 g Eu 2 o 3 (99.999%), ground and mixed evenly in an agate mortar, put it into an alumina crucible, baked at 1200°C for 5 hours, cooled to room temperature with the furnace, and ground to obtain KGd in the present invention. 0.80 Nb 2 o 7 : 0.20 Eu 3+ red phosphor. Its excitation and emission spectra are shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com